What is cad cam systems in dentistry. CAD CAM systems in dentistry

CAD/CAM stands for "Computer Assisted Design/Computer Aided Manufacturing", which translates into Russian as "Computer Assisted Design/Computer Aided Manufacturing".

CAD/CAM systems have been successfully used for a long time in various branches of mechanical engineering, as well as in the jewelry industry.

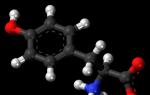

In dentistry, CAD/CAM systems are used to produce denture frameworks by computer-assisted design and CNC milling.

This is the most modern, to date, technology for the production of denture frameworks.

What can be produced using CAD/CAM systems?

single crowns and bridges of short and long length;

telescopic crowns;

individual abutments for implants;

recreate the complete anatomical shape for models of press-ceramics applied to the framework (overpress);

· create temporary crowns in full profile and various molded models.

What materials are used in CAD/CAM?

zirconia, titanium, cobalt-chromium alloy, plastic, wax.

Advantages of CAD/CAM systems compared to the traditional method:

· The highest precision of work (deviation of the sizes 15-20 microns in comparison with 50-70 microns when casting)

· High qualification and extensive experience of the system operator is not required

The system can be operated by one person

・Work space saving

Saving working time (five times faster)

Cleanliness of work

High productivity (up to 120 units per day)

Stages of the CAD / CAM system:

|

1. The plaster model enters the milling center. 2. The plaster model is scanned using a special device (scanner). The scanner converts information about the appearance of the model into a computer file. Further, with the help of a special computer modeling program (CAD-module), a framework, abutment, suprastructure, etc. are constructed on the model. The program offers a design, and the technician can change it with the movements of a computer "mouse" in much the same way as a wax composition is made on a plaster model with an electric spatula. 3. After modeling, the file with the design enters the control unit of the milling machine. Depending on the selected material, the milling machine cuts (mills) a frame from the workpiece. As a result, a three-dimensional model created earlier on a computer is embodied in the material. If zirconium dioxide was chosen as the material, after milling the structure needs to be sintered (agglomerated). 4. The zirconia frame is placed in a special sintering oven where it acquires its final size, color and strength. 5. Durable, aesthetic, accurate and lightweight frame is ready. What is needed to work with a CAD/CAM system? Premises - from 10 sq m, one operator · Scanner · Milling machine Vacuum cleaner (you can use a regular household one) zirconium dioxide framework sintering furnace zirconium oxide discs What are CAD/CAM systems? CAD / CAM systems are divided into two types: "open" and "closed". "Closed" systems are equipment that can operate only with certain consumables(discs, blocks of zirconium oxide, etc.), usually produced by one company. For example, Cerec and inLab from Sirona; Cercon by DeguDent. |

CAD/CAM (Computer- aided Design, Computer- aided manufacturing) is the collective name for modern technologies that automate the process of manufacturing orthopedic restorations. Before to create artificial crown or tab required 2-4 visits separated by several days of waiting. The waiting period was necessary for the dental technician to model and reproduce the metal or ceramic restoration. Today, thanks to CAD/CAM technology, it is possible to make a crown or inlay on a tooth within one day.

Speaking specifically, CAD / CAM is a complex that includes the following equipment:

The scanner is needed to create a virtual 3D model of the patient's teeth. There are both intraoral scanners that "digitize" the situation in the oral cavity directly, and conventional ones that scan pre-made plaster models of the patient's jaws.

The obtained three-dimensional model of the patient's teeth is processed in a computer program, where a virtual model of the future restoration (inlay, crown or veneer) necessary to compensate for the defect is created in automatic (or semi-automatic) mode for the destroyed tooth. The CAD/CAM interface is similar to a 3D editor. The doctor has the opportunity to create or change any element of the modeled restoration: the height of the cusp, the severity of the relief, the curvature of the walls, etc. When the modeling is completed, the file with the restoration model is sent to the milling machine.

The restoration that was modeled in the previous step is automatically turned on the milling machine. How this process looks like is shown in the video below. Standard ceramic or metal blanks are used as the material.

The idea of using a CAD/CAM system for the manufacture of dental restorations appeared in 1971. The first prototypes were bulky and awkward to use. In addition, the scanners used to create virtual models produced strong distortions. Today these problems are solved. The accuracy of the "digital impression" is not inferior to the impression obtained by classical technique. The software has improved significantly, and the process of virtual modeling of the future restoration has turned into creativity. The accuracy of milling machines has also improved due to the simultaneous use of several cutters and the reduction in their diameter. The following cad/cam systems are presented in Russia today: Cerec, Organical, Katana, etc.

Crowns made using different technologies may not differ in appearance. In any case, the patient will receive a highly aesthetic restoration that restores the beauty of a smile and the function of chewing food. However, the use of cad/cam systems makes it possible to simplify and speed up the production of restorations:

Firstly, the total time required to create a crown, inlay, etc. is reduced.

Secondly, instead of traditional impression materials, the doctor can use an intraoral scanner that "digitizes" the situation in the oral cavity. This eliminates the need for the patient to go through the procedure of taking conventional impressions. This is especially relevant for people with a pronounced gag reflex.

The patient directly SEES how the doctor first models an individual crown on the computer, which is then automatically machined from the ceramic block. It is beautiful)

The preparatory stage for prosthetics using CAD / CAM technology coincides with the traditional preparation of the oral cavity for treatment. It includes professional hygiene and sanitation of the oral cavity, restoration and preparation of abutment teeth.

For ideal aesthetics, individualization of the finished restoration is required: its tinting by a dental technician. This may require a separate visit.

High cost of treatment.

Using CAD / CAM, you can create any fixed structures: both all-ceramic and metal. Crowns, inlays, veneers, custom abutments, bridges, surgical guides. The range of application of this technology is constantly growing.

Before prosthetics, as a rule, it is required to perform some preparation of the oral cavity. The volume of preparatory treatment is determined by the treatment plan, which is drawn up during the consultation at the first visit to the dentist. This preparation is called “oral sanitation” and may include the following steps:

Removal of dental deposits (calculus and plaque) not only immediately improves appearance teeth, but also eliminates the source of possible future inflammation. This procedure is performed by a hygienist. At this stage, you will also learn how to properly care for your oral cavity. This is a guarantee of the long-term functioning of any restoration and structure after the completion of the main treatment.

It is performed by a dental surgeon. Often, before prosthetics, it is necessary to remove teeth or roots of teeth that cannot be restored. Such teeth include severely damaged, mobile teeth, teeth with foci chronic inflammation at the tops of the roots. In case of insufficient volume bone tissue for implantation of teeth, a preliminary operation is performed to increase it.

Treatment of caries, periodontitis, diseases of the oral mucosa, replacement of old fillings. Endodontic treatment of teeth before restoration and crowning. The need for the described manipulations in each case is decided individually. An orthopedic doctor must be confident not only in his work, but also in the quality of the work done before him. Therefore, in some cases, retreatment of the root canals of the teeth is necessary.

Bleeding gums, bad breath, loose teeth, and periodontal pockets. These symptoms are indicative of periodontal problems. They must be eliminated before dental prosthetics.

Thanks to orthodontic treatment methods, it is possible to move or change the inclination of the teeth. This preparation takes certain time(from 2-3 months to 2-3 years). However, it allows you to avoid depulpation and "grinding" of protruding or deformed teeth.

CAD/ CAM (Englishcomputer— aided design, computer— aided manufacturing) is the collective name for modern technologies that automate the process of manufacturing orthopedic restorations. Previously, it took 2-4 visits, separated by several days of waiting, to create an artificial crown or inlay. A waiting period was necessary for the dental technician to design and reproduce the metal or ceramic restoration. More details are written in the corresponding article. Today, thanks to cad/cam technology, it is possible to make a crown or inlay on a tooth within one day.

What is CAD/CAM?

Speaking specifically, CAD / CAM is a complex that includes the following equipment:

Scanner

The scanner is needed to create a virtual 3D model of the patient's teeth. There are both intraoral scanners that "digitize" the situation in the oral cavity directly, and conventional ones that scan pre-made plaster models of the patient's jaws.

Computer with appropriate software

The obtained three-dimensional model of the patient's teeth is processed in a computer program, where a virtual model of the future restoration (inlay, crown or veneer) necessary to compensate for the defect is created in automatic (or semi-automatic) mode for the destroyed tooth. The CAD/CAM interface is similar to a 3D editor. The doctor has the opportunity to create or change any element of the modeled restoration: the height of the cusp, the severity of the relief, the curvature of the walls, etc. When the modeling is completed, the file with the restoration model is sent to the milling machine.

Milling machine

The restoration that was modeled in the previous step is automatically turned on the milling machine. How this process looks like is shown in the video below. Standard ceramic or metal blanks are used as the material.

What are the CAD/CAM systems?

The idea of using a CAD/CAM system for the manufacture of dental restorations appeared in 1971. The first prototypes were bulky and awkward to use. In addition, the scanners used to create virtual models produced strong distortions. Today these problems are solved. The accuracy of the "digital impression" is not inferior to the impression obtained by the classical method. The software has improved significantly, and the process of virtual modeling of the future restoration has turned into creativity. The accuracy of milling machines has also improved due to the simultaneous use of several cutters and the reduction in their diameter. The following cad/cam systems are presented in Russia today:

- Cerec

- organic

- Katana

- and etc.

What is the difference between crowns made by CAD/CAM technology and the classical method for the patient?

Crowns made using different technologies may not differ in appearance. In any case, the patient will receive a highly aesthetic restoration that restores the beauty of a smile and the function of chewing food. However, the use of cad/cam systems makes it possible to simplify and speed up the production of restorations:

- First, it decreases total time required to create a crown, inlay, etc.

- Secondly, instead of traditional impression materials, the doctor can use an intraoral scanner that "digitizes" the situation in the oral cavity. This eliminates the need for the patient to go through the procedure of taking conventional impressions. This is especially relevant for people with a pronounced gag reflex.

- The patient directly SEES how the doctor first models an individual crown on the computer, which is then automatically machined from the ceramic block. It is beautiful)

Urgent dental prosthetics are carried out by our specialists using modern techniques of dental reconstruction. Microprosthetics, or restorative prosthetics of the teeth of the Tulskaya metro station, allows us to restore the crowns of the teeth even with their significant destruction.

The prosthetics of the front teeth and the restoration of the beauty of your smile are carried out by Organic Dent doctors technically perfectly and with impeccable aesthetic taste. We also widely use gentle dental prosthetics without turning.

Types of dental prosthetics in Organic Dent.

In our clinic, we carry out dental prosthetics, the types of which are the most reliable, and therefore the most popular among residents of Moscow.

Dental prosthetics at Tulskaya metro station with metal-free E.max ceramics, designs for which we manufacture using CEREC equipment. E.max metal-free ceramics are good for their high aesthetics and absolute naturalness of the result. In addition, our prices for such prosthetics are quite democratic. Therefore, when choosing dental prosthetics in Moscow, take the cost of our services as an additional argument for Organic Dent.

As a sparing prosthetics of the anterior teeth, we offer veneering - correction of the frontal surfaces with the help of a progressive filling material. Technology achieves great aesthetic effect at minimal cost for prosthetics in Moscow, therefore it is often used for the restoration of the smile zone.

Dental prosthetics in Organic Dent is also traditional ceramic-metal, removable and non-removable dentures, but the main thing is beautiful teeth and real comfort as a result. If you need high-quality dental prosthetics, Tulskaya will take you to Organic Dent, where experienced doctor make your teeth perfect.

Dental prosthetics Moscow.

In conclusion, we would like to give you a few practical advice:

When planning dental prosthetics, be sure to compare prices with the level of services provided. When calling the clinic, always ask how much dental prosthetics cost. Organic Dent will advise you in this regard in detail.

be interested warranty obligations. Our dentistry gives a one-year warranty on all types of dental prosthetics.

Look for dentistry where it's convenient for you. For example, enter Danilovsky prosthetics in the search bar - and you will get the answer: Organic Dent - here your smile will become an object of admiration.

It should also be said that our dentistry considers prosthetics priority. This guarantees you a luxurious result and an unprecedented quality of services.

If this definition seemed complicated to you, then we will give an example for clarity. Previously, the crown was placed over several visits (2 to 4), and they were separated by several days of waiting. This was necessary so that the crown technician could correctly design and reproduce a ceramic or metal restoration. Today, thanks to CAD / CAM technologies, the manufacture of a crown or inlay on a tooth takes place within one day! After all, using them, you can create any non-removable structures: crowns, inlays, veneers, individual abutments, bridges, surgical templates. Moreover, they can be all-ceramic or metal. And every year the range of application of cad cam technologies expanding in dentistry.

What is CAD/CAM technology?

This is a set of equipment that includes:

- Scanner. It is necessary to create a 3D model of the patient's teeth. There are intraoral and conventional scanners (they scan plaster models of the jaw).

- computer with special software. It processes the resulting three-dimensional model, and then automatically or semi-automatically recreates a virtual model of the future tooth (inlay, crown or veneer). The CAD/CAM interface is very similar to a 3D editor program. The technician can create or change any element of the restoration (curvature of the walls, the severity of the relief, etc.). When all changes are made, the file with the restoration model is sent to the machine.

- Milling machine. On it, a restoration modeled in the program is automatically machined from metal or ceramic.

Types of CAD/CAM systems

CAD/CAM-systems appeared a long time ago, but they began to be used in dentistry only in 1971. The first prototypes of the system were bulky and inconvenient, and the scanners distorted the virtual models. But today all these problems are solved. The accuracy of digital models is not inferior to the impression obtained in the classical way.

Several types of CAD/CAM systems are used in Russia: Cerec, Organical, Katana, etc.

What are the differences between crowns obtained by the classical method and using CAD / CAM technologies?

By outward signs crowns made in different ways are almost the same, the patient will in any case receive a highly aesthetic restoration. However, the use innovative technologies allows you to simplify and speed up the process of manufacturing crowns, inlays, etc. In addition, the doctor uses an intraoral scanner instead of the traditional impression material, which allows the patient to avoid the procedure of taking conventional impressions. This will certainly please patients with a pronounced gag reflex.

Cad/Cam technologies in dentistry for 3d modeling of teeth – new project automation and autonomy of the laboratory of dental technology. Applying it in practice, you will achieve an increase in the quality of products, their improvement and reduce production time.

Translated from in English Computer-Aided Design / Computer-Aided Manufacture - computer-aided design / manufacturing systems, abbreviated as CAD. They appeared back in the 1980s and were found in a completely different area, namely in the industry for the manufacture of metal-cutting machine tools for high-precision machining of parts and the production of automobiles. In recent decades, this niche has been developed and implemented in various fields, including dental technology. Now computer programs and equipment help at all stages - from development to the implementation of finished parts. Therefore, no area of medicine is left without the help of innovative electronic technologies.

Technologies and systems Cad / Cam (Cad / Cam) in dentistry, together with materials that do not contain metal, are used by practicing doctors and the largest laboratories to produce:

- milled ceramic crowns;

- tabs; all-ceramic bridges;

- veneers;

- abutments in implantation.

In the program, you can recreate a three-dimensional anatomical shape for molded ceramic blanks, which is applied to the framework, design temporary crowns in full profile and visualize other casting models.

Over time, computer technology and materials have been improved and transformed. Cad/Cam dentistry involves computer-aided design and product development methods that are used as an alternative manual way drawing. The object is viewed from any angle, and its projection can be viewed in a certain light. Also, any part of it can be revised, changed. The design of the element can be completely rebuilt from scratch. After the project is clarified and approved by specialists, detailed drawings with numerical designations of dimensions are printed out and transferred for production.

With these possibilities modern medicine offers high quality restorations used in the practice of dental specialists and dentists in prosthetics. Those models that are made using new technologies are characterized by the best properties fit, biocompatibility, increased strength and aesthetic appearance.

Stages of creating a part

In many dental laboratories use CAD, thanks to which technicians are engaged in design using specialized software:

- At the very beginning of work in the system, a 3-dimensional display of one or several objects to be restored is displayed on the screen. It was obtained by scanning with an optical scanner. A 3D image is also obtained by scanning a part made in a standard way - a regular cast.

- Sketches are placed in a special program for modeling and finishing the restoration. This is what a dental technician does. The amount of time spent on a full cycle depends on the experience, skill of the employee and the level of complexity of the task. In some cases, all actions take several minutes, for others it will take more than one hour to achieve an impeccable result.

- After the completion of the process, the designed part is given for milling from an all-ceramic piece in a grinding chamber (on a computerized machine).

- For greater naturalness, the restoration is additionally covered with ceramics and placed in a kiln for firing.

- After the material has completely hardened, the prosthesis is ground and polished.

The program for dentists for 3D modeling of teeth has proven itself from a very good side - it not only speeds up the creation process, but also makes the result more accurate and improved in terms of characteristics. If we compare it with traditional manufacturing, it turns out that computer technology does not need a large area, does not pollute the room in the same way as the casting method. The master can maintain the system alone, which saves time and money.

Such a system will not replace the professionalism, talent, experience of doctors and dental technicians. Sufficient qualification of specialists in the field of initial preparation of the cast, accuracy during the creation of a digital impression and a three-dimensional image of the restoration - mandatory conditions successful work. Prevention of early damage to the element and the duration of its use depend on this. Bad crowns may have gaps between healthy teeth and the installed restoration, which increases the risk of infection.

What opportunities opens up a computerized system

The standard manufacturing system for dental restorations is based on casting technology. The prostheses are held on a frame made of cast metal with a ceramic coating. Temporary crowns made of zirconium oxide and zirconia are now gaining popularity. In fact, this is one of the varieties of ceramics. The advantages of such products are their impeccable appearance and high strength. Without a metal base, the model looks more natural. Zirconium oxide is inert. Allergy or rejection of materials is almost impossible, which is not excluded in the case of using other materials.

Such a base cannot be obtained by casting. In its raw form, a bar of zirconia is a malleable material that vaguely resembles chalk. After firing at 1350 degrees, it becomes strong and hard, like ceramics. With thermal exposure, the part “shrinks” and the crown decreases in size. That is why manual production of such restorations is undesirable.

The use and production of such prostheses took place only thanks to the introduction of innovative computer technologies Cad/Cam.

List of modeling programs to help the dentist

There are many CAD systems for 3D design of teeth for the purpose of their subsequent manufacture. Most Popular:

- DentaPro;

- Dentist+;

- Denta lAccord;

- dental cloud;

- ClinicIQ;

- QStoma;

- Adenta;

- Dental4Windows;

- iStom;

- infodent;

- IDENT;

- DENT;

- Dental-Soft;

- 1C: Dental clinic.

But technical progress has a positive effect on the development and implementation of new software, and therefore AutoCAD, ZWCAD and other design programs and visualizers are being improved, developed and become reliable assistants to dentists and dental technicians.

|

|

|

|

|

Using the Cad / Cam program for dentistry, computer modeling of teeth

Quality monitoring shows that the current restorations are stronger and better than prostheses made without the use of offline design systems.

ZWSOFT implements a new generation of CAD. ZWCAD 2018 is getting more and more popular among users. The product is in demand for a number of reasons:

- support for DWG format drawings;

- user-friendly interface;

- powerful collection of tools;

- the price is comparable to the functionality.

The 2018 version has an updated UI styling and also includes more toolbar customization options. A nice addition in the form of a built-in calculator in the sidebar and the ability to quickly create clarifications and drawing caps makes it easier to complete tasks and save time. The licensing policy of all ZWCAD products makes it possible to independently choose the right one for the set of functions, the appropriate option for performing tasks of any level of complexity and not overpay for options that the client does not need.

The big advantage of equipping clinics and laboratories with the right equipment and software is the ability to offer patients dental restoration in just one visit. Cad/Cam Cerec systems in dentistry are used to deliver crowns, inlays or veneers to a client in one visit. positive moments is the fact that local anesthesia It is also carried out once at the time of preparation for the procedure.

An all-ceramic bridge cannot be placed in this way, since its production takes more time and is carried out in a laboratory.

Types and comparison of characteristics of versions of ZWCAD 2018

Each program has a different set of features, but all have high efficiency indicators. In general, this software is an analogue of ACAD. The software is affordable, and therefore suitable for both full-fledged dental technology laboratories and a newly opened institution. Regarding the cost of updating the software, we recommend that you consult with the company manager, as there are versions with paid and free upgrade options.

Consider the basic tools for a dentist suitable for 3d modeling.

standard version

The set of functions allows you to view and edit the properties of the selected object through the properties palette, and also includes:

- opening/saving files in DWG, DXF, DWT format;

- five modes of editing objects through handles;

- correct display of CAD objects in the amount of 65 types;

- the ability to customize the drawing;

- CUI editor;

- automatic completion of input;

- interface switching;

- LISP, COM, ACTIVEX.

The buyer can test not a demo, but full version, making sure of the benefits of the software before making a purchase. To create dental restorations, it is recommended to choose more advanced software.

Professional version

This software includes all the features of the previous version, and also has additional ones:

- the possibility of 3D modeling and editing;

- integration with other external applications;

- VBA/.Net/ZRX support.

Classic variant

Equipped least amount opportunities. Supports 2D/3D, has an intuitive interface and basic design kit. It makes it easier to learn how to work with similar software. This option can also be tested before purchase, but upgrades are no longer supported.

Benefits of using CAD and free dental design software

Software in medicine today has become an integral part of the different stages from diagnosis to surgery.

Its advantages for dental laboratories:

- Significant reduction in the production time of restorations. Their modeling takes place in a few minutes. Automatic processing and construction of visualization in the cam system reduces time costs and human resources.

- Adjustment and improvement of such technologies includes a preliminary consideration of the percentage of raw material shrinkage during firing. The master receives a size that is completely identical to the scanned print.

- Optimization of the working time of dentists and technicians, contributing to the correct prioritization of tasks.

- No need to involve third parties for the manufacture of prostheses.

- Special training restorations made of zirconium oxide and other specific materials - titanium or aluminum oxide.

By purchasing the products of our company, you get high-quality computer program for dental technicians at a low price. For an analogue of ZWCAD 2018 - software from Autodesk - you will pay much more. The right software will make it easier to complete tasks of any level of complexity. A modern clinic must provide a proper approach to its clients. quality equipment and modern technologies help to simplify the process and reduce time and financial costs. We offer customers to purchase tools for their specialty - easy to operate and efficient in work.