The choice of cable for street lighting. Which cable to choose for lighting. Laying along the facade of a building or between buildings

Wiring without junction boxes is an installation technique that has been developed relatively recently, in some respects it has positive aspects and does not contradict the requirements of the PUE and PTEEP guidelines. But it also has flaws and causes a lot of controversy in professional circles. We will tell in the article about all the nuances of its installation.

In what cases do they prefer to use installation without junction boxes

The main argument that attracts customers to use this technique is the absence of junction boxes on the top of the walls. It is believed that they spoil the look of the interior, the covers do not always fit into the picture of the overall design. If they are covered with wallpaper or plaster in the event of a malfunction in the network, the destruction of individual sections is required to eliminate them.

When opening the box, it becomes necessary to tear off part of the wallpaper or destroy plaster coatings, gypsum molding and other interior elements. In fact, this leads to a large-scale repair, which requires no small amount of labor and money.

To get rid of the prospect of destroying the results of expensive repairs, they resort to methods of installing electrical wiring without using junction boxes. Read also the article: → "". This is in the interests of customers, but the technique has an attractive side for installers, labor costs are reduced, there is no need to hammer holes for boxes and make strobes from them.

Council number 1. If you have expensive wall finishes, run underfloor wiring without junction boxes.

Wiring solutions without junction boxes

In some cases, the PUE even requires that this be done, it is forbidden to enter the junction box and make branches from the lines that power electric stoves, heating boilers, air conditioners and other devices that consume large amounts of electricity. For them, a dedicated circuit breaker is installed in the switchboards, from which its own cable line is laid, this entire circuit is a separate group.

In this case, in the power supply circuit of a house or apartment, there may be several outlet groups with separate circuit breakers in the switchboard. They can be divided into different rooms or there can be several rooms on the same line, there are many options. The choice is determined by the customer, coordinating the technical capabilities with the contractor (electricians).

In this case, in the power supply circuit of a house or apartment, there may be several outlet groups with separate circuit breakers in the switchboard. They can be divided into different rooms or there can be several rooms on the same line, there are many options. The choice is determined by the customer, coordinating the technical capabilities with the contractor (electricians).

In lighting networks, they do the same, difficulties arise only with the installation of switches in these lines. But the problem is solved, all the necessary connections are made in the box in which the light switch is installed. Current loads in lighting circuits are usually much less than in a socket group, so the wires are thinner. This allows you to pack the contact groups of connections without prejudice to the installation of the switch device in the landing box.

Conductors with 4-6 mm 2 conductors were laid between the junction boxes, and taps were made from it for individual sockets and lighting fixtures with thinner wires. The common wire was designed for the load of all consumers in the group. In our version, a section of 4-6mm 2 will not be very convenient for connecting to contacts and packaging in socket boxes.

Such wires are rigid, it is difficult to clamp the bolted connections of the contacts, sometimes the terminals even break. It is very convenient to use copper wire 2.5 mm 2, it is elastic and fits perfectly into the grooves of the terminal. The current loads that the conductors are able to withstand can be found in the table. Based on this, make calculations on the number of outlets in the group and the power of connected household appliances.

| sections of copper conductor for various current loads | ||||||||||||||

| Current in A | 1 | 2 | 3 | 4 | 5 | 6 | 10 | 16 | 20 | 25 | 32 | 40 | 50 | 63 |

| S-in mm 2 | 0,17 | 0,33 | 0,52 | 0,67 | 0,84 | 1 | 1,7 | 2,7 | 3,3 | 4,2 | 5,3 | 6,7 | 8,4 | 10,5 |

| Ø in mm | 0,45 | 0,65 | 0,81 | 0,92 | 1,02 | 1,13 | 1,45 | 1,87 | 2,05 | 2,32 | 2,60 | 2,92 | 3,27 | 3,66 |

Based on the calculated values, a wire of 2.5 mm 2 can withstand a load of up to 16A. Data of approximate powers and currents consumed by household appliances for various purposes has been collected. Using this information, you can guess how many and which devices to include in the outlet group.

| Type of household appliances | power in W | current in amperes |

| Incandescent lamps of old designs | 60 – 250 | 0,3 – 1 |

| Small-sized heating appliances kettles, coffee pots and boilers | 1000 – 2000 | 5,5 – 10 |

| Stationary and portable electric stoves | 1000 – 6000 | 6 – 55 |

| Microwaves of various brands | 1500 – 2200 | 8 – 10,5 |

| Kitchen electric meat grinders for non-industrial purposes, for home use. | 1500 – 2200 | 8 – 10,5 |

| Bread toasters | 500 – 1500 | 2,5 – 8 |

| Grill cooking equipment | 1200 – 2000 | 7,5 – 8 |

| Blenders and mixers | 500 – 1500 | 2,5 – 9 |

| Food processors | 500 – 1500 | 2,5 – 9 |

| electric oven | 1000 – 2000 | 5,5 – 8 |

| dish washing machines | 1000 – 2000 | 5,5 – 8 |

| Household washing machines | 1200 – 2000 | 5.5 – 8 |

| Electric dryers for shoes or clothes | 2000 – 3000 | 8 – 12 |

| Non-industrial irons | 1200 – 2000 | 5.5 – 8 |

| Floor and portable vacuum cleaners | 800 – 2000 | 3.5 – 8 |

| Spiral heaters | 500 – 3000 | 1.8 – 12 |

| Hand dryers for hair drying | 500 – 1500 | 1.5 – 7 |

| Split systems and air conditioners | 1000 – 3000 | 6 – 12 |

| computers | 300 – 800 | 0.8 – 3,2 |

| Hand power tools (grinder, drill, punchers, jigsaw, etc.) | 500 – 2500 | 1.8 – 12 |

Features of mounting sockets without junction boxes

From the machine in the switchboard, the wire of the socket group is laid in a common gate with cables of other groups. In places of branching, it does not start up in junction boxes, it leaves along its route in a separately laid strobe. In the sockets, a loop is made 15 cm long. This part of the cable is intended for cutting and connecting to the contacts. This is a proven method of laying the cable, then there are several methods for cutting the cable and connecting to the contact group of sockets.

Wiring with line break

To connect the wires to the terminals, the loop is bitten in the middle, the outer sheath is removed from the cable by 10 - 15 cm, the ends of all wires are stripped 1-1.5 cm from the insulation. The bare ends are attached to the contacts in accordance with the color assignment.

- Blue wire - to the neutral contact;

- Red brown or black per phase contact;

- Yellow - green on the ground terminal.

On each contact, two wires coming from the switchboard and going to the next outlet are clamped.

Everything would be fine if it were not for the contradictions with clause 1.7.144 of the PUE (Electrical Installation Rules). The ground wire, designated PE, must be attached to a separate terminal from each consumer (sockets with a household appliance turned on). The yellow - green conductor must be solid along the entire length, from the switchboard to the outlet. Non-separable connections in junction boxes are allowed in the form of welding, soldering, or crimping with special sleeves. In our case, there are no junction boxes, so this method in relation to the PE wire does not meet the requirements of the wiring guidelines. Some electricians neglect this, this is a big mistake.

Everything would be fine if it were not for the contradictions with clause 1.7.144 of the PUE (Electrical Installation Rules). The ground wire, designated PE, must be attached to a separate terminal from each consumer (sockets with a household appliance turned on). The yellow - green conductor must be solid along the entire length, from the switchboard to the outlet. Non-separable connections in junction boxes are allowed in the form of welding, soldering, or crimping with special sleeves. In our case, there are no junction boxes, so this method in relation to the PE wire does not meet the requirements of the wiring guidelines. Some electricians neglect this, this is a big mistake.

Grounding wires connected between sockets may lose reliable contact. This is facilitated by a long load with high currents, an iron or an electric heater, a hair dryer and other household appliances. When heated, the metal elements on the contacts expand, after the load is turned off they cool down, over time this leads to a weakening of the bolted connection of the contact group. The bolts on the contacts must be periodically tightened, otherwise it may cause a fire.

In the case of a PE conductor, the danger is doubled, it is the most important element in the human protection circuit, the RCD (touch protection device) eliminates electric shock, instantly turns off the network. If in the circuit at one of the sockets the ground wire does not have a reliable contact, this socket and all subsequent ones will remain unprotected. There will be a threat of current passing to the body of household appliances connected to sockets, the protection will not work, touching the metal parts of household appliances will lead to electric shock. Therefore, electricians who use this connection method take great responsibility on their conscience.

This method allows you to follow the connection rules regarding the ground wire. Without cutting the wires on the loops in the sockets, the outer sheath is removed from the cable. The wires in the loop of each conductor are folded, the insulation is removed at the tip, while the conductive core remains intact.

This method allows you to follow the connection rules regarding the ground wire. Without cutting the wires on the loops in the sockets, the outer sheath is removed from the cable. The wires in the loop of each conductor are folded, the insulation is removed at the tip, while the conductive core remains intact.

The bare ends are attached to the contacts, in this case, even if the contacts on one of the sockets weaken, this will not de-energize the rest of the sockets. In the case of a PE conductor, the sockets will be connected to the protection system, since the wires remain intact, there will be no break in the common circuit, only one socket will turn off.

In this case, the circuit is assembled in the classic version, as in a junction box. Only the outlet to the outlet will be very short, no more than 10 cm, and not from the ceiling to the floor, as is done using junction boxes.

The ends of the incoming and outgoing cable for cutting and connecting should also be made shorter, no more than 10 cm. This will allow compactly packing the twists with insulation at the bottom of the socket so that they do not interfere with the installation of the socket itself.

Connecting wires in the socket

Features of installation of lighting networks without junction boxes

As in the socket groups, the goal of the technique is to reduce contacts, labor costs and increase reliability. It is possible to use two-wire wires for single-gang switches, but it is recommended to lay a cable with three wires. This is due to the fact that modern chandeliers and lamps have a ground wire terminal on the body, it is better to fulfill all safety requirements.

Network connection with single-gang and two-gang switches

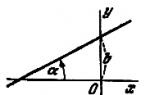

For a better understanding, in a simplified diagram, we will consider the connection methods, from the switchboard to the nearest switch we lay the phase wire, pull the zero and ground wires to the lighting device. Grounding is attached to the body of the lamp, N - a neutral wire to the contact of the lamp holder.

The phase wire is fixed on the incoming contact of the switch, a conductor is laid from the outgoing contact to the free contact of the lamp holder. All technology is not tricky, the complete absence of unnecessary contacts and junction boxes. If there are several elements in the lighting group in different rooms, we make connections in the box of the first switch and lay the line further. As in socket groups, connections can be made at the switch terminals. In the classic version, the contacts are twisted, insulated, packed at the bottom of the switch box.

The diagram shows the connection of a single-gang switch and a two-gang switch in the same group.

Advantages and disadvantages of mounting without junction boxes

The advantages of the technique without junction boxes are:

- Reducing contact connections, which reduces the likelihood of emergencies;

- Reduced labor costs at the stage of installation work;

- Simplicity of the connection scheme, in the absence of numerous ends in junction boxes, the probability of errors during connection is reduced;

- For customers, reducing wiring elements, in this case junction boxes, reduces the cost of work.

- Improving the interior of the premises;

- During maintenance and repair, the need to destroy decor elements on the upper sections of the walls is eliminated.

The disadvantages include the following points:

- Non-standard connections make it difficult to repair and maintain wiring by electricians who did not participate in the installation process;

- An increase in the number of groups, and therefore wires. This statement is debatable, the wires from the boxes to the sockets are excluded, so the difference in the length of the consumable wires is not significant.

- In some areas, it is necessary to remove the outer sheath of the cable from the wires, as a result of which there is no double insulation element.

Tip # 2 The last drawback is easily eliminated, before laying, put cambric on the wire or lay a separate wire with good insulation in this area.

Frequently asked Questions

Question number 1. The wires will be plastered, is it possible to lay wires with insulation that does not match the color of the destination in some areas?

You can lay the wires in general in one color of white or blue, any that you have. The main requirement is that there is reliable insulation, and the cross section corresponds to the load. In order not to get confused, it is necessary to put on a cambric, a heat-shrinkable tube or an insulating tape of a color according to the functional purpose of the wire:

- Blue - zero;

- Red, black, brown - phase;

- Yellow - green - grounding.

Question number 2. If you use sockets and switches not with bolted contacts, but with clamping contacts on springs, there is no need to periodically pull the contacts, a break in the sequence is eliminated. So you can carry out the installation by biting off the wires at separate intervals?

The spring group of contacts does not give one hundred percent reliability, in addition, the requirements of the PUE are violated. If there is no contact on the PE wire, the likelihood of electric shock through the housing of household appliances increases. What prevents you from making loops on the wires, stripping the ends without breaking the current-carrying core and inserting them into spring contacts. All rules are followed and reliability is increased.

Question number 3. If you connect wires of different sizes to the outlet, is this allowed?

The cross section must correspond to the calculated current load, more is possible, provided that this does not interfere with the compact packaging of the connections in the sockets.

Question number 4. Can the ground wire be laid to the chandelier body at the shortest distance from the ceiling plate fittings?

Usually the reinforcement of reinforced concrete structures is grounded, but where is the guarantee that the individual elements are part of the overall circuit. It is necessary to measure the ground resistance, why do you need these problems, pull the wire from the switchboard.

Question number 5. There is no contact for a ground wire on the chandelier body, what should I do?

It is a sin to advise such, but do nothing. This is a deviation from the rules, but in our reality it often occurs. Make a two-wire connection, given that children will not climb the ceiling, and adults, before changing the light bulb, turn off the switch, there is nothing to worry about. If the body of the chandelier does not have metal structures, plastic or other non-conductive materials, then there are no violations.

Electrical sockets switches - a necessary element in any apartment. The installation of such parts requires compliance with the conditions for height, distance, and others. The basic rules are relevant for the location and installation of sockets and switches in various rooms, and in the living space, the design of these elements is also important.

Technical requirements for the installation of sockets and switches in the apartment

Switches and sockets are used to control lighting. Elements of the electrical network need to be properly installed. For this, there is a set of requirements, which includes the main points that must be taken into account during installation. At the same time, the requirements are of a general nature, and the rules are necessary to ensure safety.

The most modern are the requirements of the European standard.

Eurostandard assumes a convenient arrangement of elements

The recommended installation height of the switches is 90 cm from the floor level. This arrangement makes the elements of the electrical circuit invisible in the general interior of the room. Ease of use is also an advantage of the location of the switches. The distance from the edge of the door to the switch must be at least 10 cm.

Previously, the elements of the electrical network were mounted in accordance with the rules of the Soviet standard. In this case, the switches are located at a height of 160 cm, which often causes inconvenience. The rules are optimal for residential premises. In manufacturing plants, public places and other similar areas, slightly different bases are used when installing switches and sockets.

Security measures

Correct installation of elements will ensure safety

It is especially important to comply with the requirements for safe installation in rooms with high humidity. In the bathroom, the details of the electrical circuit are installed outside, and not inside the room. When carrying out any kind of work on the electrical system, it is important to first disconnect the voltage. After that, you need to make sure that there is no stray current, and for this a voltage indicator is used. The ends of the bare wire, through which the current supply is turned off, are additionally checked with a fingertip, but you cannot clasp the element with two fingers.

Read also our material with instructions for transferring, replacing and repairing switches and sockets:.

Preparatory work

Proper installation of any elements of the electrical system involves preparation. For this, the location of each element is determined. Outdoor devices are mounted on the wall surface and do not require the use of complex tools. For built-in types of sockets and switches, holes must be made in the wall according to the size and shape of the part. You also need channels for laying wires. Trenching of furrows is carried out with a complete replacement of electrical wiring and switches. After preparing the holes, the sockets are installed.

Design

Before installing switches and sockets, it is important to determine their location, the place for the junction box and other significant points. This takes into account the location of household appliances. In the living space, sockets and switches are needed in every room.

The kitchen uses a lot of sockets

For outdoor location

When placing elements outside the wall, special types of sockets and switches are used - overhead. A preliminary plan is drawn up for the location of all the details. The installation process then includes the following steps:

- a wooden block made of plywood with a thickness of about 10 mm is attached to the place for the socket or switch. The size of the element must exceed the dimensions of the outlet by 20 mm;

- from the new outlet, remove the upper plastic box and remove the plug covering the place for the wire;

- the terminal block is screwed to the block with self-tapping screws, and the electrical wires are connected.

Outdoor sockets do not require a complex set of works

For indoor location

The internal placement of switches and sockets allows you to make them more compact. At the same time, the preparatory stages of work consist in making grooves for the cable, making holes for the sockets. To do this, use a hammer drill with a suitable "cup" type drill. In this case, the depth of the hole should be equal to the height of the walls of the socket box.

Video: installation of socket boxes

With a low arrangement of devices, it is possible to direct the channel for the wire down, while the cable is further laid under the plinth and there is no need to gouge many holes.

The cable is easy to lay along the technological channel

A socket is installed in the hole, wires are output, to which the switch or socket is attached. Finally, the top cover is fixed.

Clear hole size allows easy mounting of the part

The internal design of sockets and switches has a single device principle. These details are especially diverse in appearance. Models with a white case are classic, but there are also color options. Also, when designing interior design, various methods of designing elements of the electrical system are often used.

The original decor will easily disguise all the elements

Sockets and switches can be easily matched to the same color of the walls. If this decor option is not possible, then it is best to arrange the elements in an unusual way. If possible, sockets and switches are hidden behind furniture, decor items and other details. At the same time, it is important to prevent foreign parts from getting inside the devices. If children live in the room, then special plugs and “curtains” are used.

See also the material on the arrangement of electrical retro wiring:.

Do-it-yourself standards for height, location and installation of sockets and switches

The standards for installation, operation of various parts of electrical systems are regulated by the Electrical Installation Rules (PUE) and GOST. These standards require compliance with the basic standards for the selection, installation and operation of devices. This ensures the safety and high quality of the systems.

Installation height according to PUE

The main points of the PUE regarding the installation of switches and sockets suggest the following features:

- the minimum distance from switches, socket outlets and elements of electrical installations to gas pipelines must be at least 0.5 m;

- any switches and sockets must be located at least 0.6 m from the doorway of the shower cabin.

switches are recommended to be installed on the wall from the side of the door handle at a height of up to 1 m, it is allowed to install them under the ceiling with a cord control. In the premises for children to stay in childcare facilities (kindergartens, nurseries, schools, etc.), switches should be installed at a height of 1.8 m from the floor;

Requirements for placement in accordance with GOST and SP

According to the established GOST standard, the number of sockets and switches in a residential type room is determined by the user. At the same time, the rules for the placement of these elements are observed. The distance from sockets to kitchen stoves and air conditioners is not standardized.

European installation height

The European standard assumes a convenient and safe location of the elements of the electrical network. The height of the switches is from 90 cm from the floor level. Sockets can be located at a height of 30 cm.

Layout plan makes it easy to install sockets

Nuances of requirements for various institutions

In rooms and institutions where children of any age stay, sockets and switches are located at a height of about 1.8 m from the floor level. At catering establishments, sockets are mounted at a height of 1.3 m. The height of the lighting fixtures and their power are selected depending on the convenience of users and work efficiency.

You may be interested in the material on installing and connecting a cross switch:.

Myths about installation requirements

The established requirements are basic for the installation of sockets and switches in residential and other premises. In this case, you can use the free method of location, that is, fix the elements in an order that is comfortable for the user. This option is often considered the only one, but we must not forget about the standards that ensure security.

Video: self-installation of switches in the room

All elements of the electrical circuit are important and require safety during installation and operation. Compliance with requirements and standards is a solution necessary to achieve high quality work.

With an abundance of household appliances and a variety of lighting fixtures, the need to increase the number of sockets and switches in a house or apartment has increased dramatically. In the current apartment of 100 sq. m, on average, there are a hundred electrical outlets. The question of their rational location and installation is far from idle and requires knowledge of regulatory documentation. Starting transformations in a house or apartment, it is useful to familiarize yourself with the provisions of the laws and the technical regulations for the installation of electrical appliances.

Technical requirements for the installation of sockets and switches

Locations inside and outside residential premises are selected based on 3 main criteria:

- safety;

- functional convenience;

- aesthetic appeal.

Security includes 3 points:

- Natural gas. Poorly tightened contacts lead to burnout of the terminals. The principle of operation of the switch is such that when the lamp (or other consumer) is turned on, the power circuit is closed. This happens due to the movement of the contact pair. At this moment, a micro spark jumps between the contacts, capable of igniting the gas. If there is a leak in the gas supply, the switch may cause a fire or explosion. The same happens if the switch or socket is faulty. Poor connection of wires supplying voltage to the device, loose contacts, etc., lead to sparking at the terminals. It is for this reason that in apartments with gas stoves and water heaters, the light switch is moved outside the kitchen. Usually it is installed in the corridor, separated from the kitchen by doors. Sockets have a different logic. The gas is lighter than air and therefore accumulates first in the upper part of the room. Therefore, it is better to place the socket in the kitchen closer to the floor, in which case the probability of gas ignition from a spark is lower.

- Water.

Water is not compatible with electricity. Any liquid is an excellent current conductor. If water enters between opposite contacts, a short circuit occurs between them. But this is not the worst. In the event of a short circuit, circuit breakers will trip and the electricity will be turned off. It is much worse if one of the contacts is wet - the voltage is transmitted through the water in all "wet" directions. If a person (or animal) touches the moisture, he will be shocked. In the event of a leak from the water supply (or water heating systems), puddles formed on the floor become a potential risk area. Electric shock is fraught with human health - there are known cases of cardiac arrest and the occurrence of a number of other neurological diseases. Therefore, the location of the sockets is planned taking into account the possibility of flooding. Placing them at a safe distance from the floor, as well as other sources of water in the house, makes good sense.

Water is not compatible with electricity. Any liquid is an excellent current conductor. If water enters between opposite contacts, a short circuit occurs between them. But this is not the worst. In the event of a short circuit, circuit breakers will trip and the electricity will be turned off. It is much worse if one of the contacts is wet - the voltage is transmitted through the water in all "wet" directions. If a person (or animal) touches the moisture, he will be shocked. In the event of a leak from the water supply (or water heating systems), puddles formed on the floor become a potential risk area. Electric shock is fraught with human health - there are known cases of cardiac arrest and the occurrence of a number of other neurological diseases. Therefore, the location of the sockets is planned taking into account the possibility of flooding. Placing them at a safe distance from the floor, as well as other sources of water in the house, makes good sense. - Mechanical damage.

Switch falling out due to mechanical damage The vast majority of sockets and switches are made of plastic. Plastic is an excellent dielectric and reliably protects a person from contact with current. Its only weak point is its fragility. A strong blow can damage the body of the device with all the ensuing troubles - failure, exposure of contacts, etc. Therefore, their placement is planned in such a way as to minimize the threat of mechanical damage. Particular attention should be paid to this with external wiring, when the socket and switch housing are completely outside the wall.

Switch falling out due to mechanical damage The vast majority of sockets and switches are made of plastic. Plastic is an excellent dielectric and reliably protects a person from contact with current. Its only weak point is its fragility. A strong blow can damage the body of the device with all the ensuing troubles - failure, exposure of contacts, etc. Therefore, their placement is planned in such a way as to minimize the threat of mechanical damage. Particular attention should be paid to this with external wiring, when the socket and switch housing are completely outside the wall.

The ease of use factor is hard to overestimate. A person uses both switches and sockets many times a day. If discomfort is experienced at the same time, the device must be reinstalled without delay. It is also important to remember that switches and sockets must be easily accessible in emergency situations. Do not clutter them with furniture or install in hard-to-reach places.

Video: inconvenient location of sockets and switches

Any interior is arranged according to the taste and aesthetic preferences of the inhabitants of the housing. Sockets and switches are also part of the interior. Therefore, their "artistic" design has the right to exist. You can always choose the color, size and shape. Modern industry offers a wide and varied range of power supply and lighting control devices. With the help of imagination and fantasy, you can create unusual design solutions. But not at the expense of safety and ease of use!

Switch decoration

Switch decoration It has been observed that dogs avoid outlets and try to stay away from them. At the same time, cats, on the contrary, are supportive of electric fields, often resting on refrigerators, televisions and computers.

Do-it-yourself installation safety measures

During installation work, safety precautions must be observed.

On the scale of home repair, it consists of three basic rules:

Preparation for installation, correct design

Installation and reinstallation begins with a detailed plan. It reflects the exact location of each device, size and quantity. When developing a project, the location of power lines and junction boxes should be taken into account. Choose the correct height from the floor level. The more detailed the plan and the better it is tied to the “locality”, the less costs will be needed to implement it. Practice has shown that a well-thought-out project saves up to 20% of funds and up to 30% of time.

Video: sockets in the kitchen

In order for the project to fully correspond to the real picture, it should reflect:

- Door and window openings.

- Location of furniture, household appliances and computer network.

- Areas of increased danger: water supply and gas pipelines.

It is very important to choose the correct section of current-carrying cables. The total power of consumers should not exceed the capacity of the conductor. Sockets and switches are selected factory-made and with nominal characteristics corresponding to the network parameters. (230 V and 6 A).

In children's rooms, it is advisable to install sockets with automatic shutters. In bathrooms - devices with an IP 66 index (an indicator of maximum moisture resistance). Outside the house, it is recommended to use sockets equipped with a cover.

Sockets equipped with additional protective equipment are installed

Sockets equipped with additional protective equipment are installed You should also follow simple rules:

- The distance between switches and engineering communications systems is at least 0.5 m.

- The distance from the kitchen sink is at least 0.8 m.

- The gap between the switch and the door (window) trim is from 0.1 m.

- For stationary electrical appliances (TV, washing machine and dishwasher, computer), separate sockets are installed located in close proximity to them.

For outdoor location

Outdoor wiring has a number of undeniable advantages. First of all, it is the availability of the entire power line and the relative ease of installation. For this type of wiring, it is not necessary to ditch the walls and install socket boxes at each point. In the case of reformatting the wiring, all lines can be quickly and easily dismantled without disturbing the appearance. Also easy to reassemble. The use of cable channels allows you to add new lines mobilely if necessary.

External wiring device using cable channels

External wiring device using cable channels The cabling in the form of twisted pair on insulators gives the interior originality in the retro style.

Twisted Pair Cabling

Twisted Pair Cabling However, some characteristics disadvantageously distinguish outdoor wiring from hidden wiring. This is a greater risk of mechanical damage and contact with conductive (or combustible) wall surfaces. Therefore, during installation, additional protective measures are provided. So, for example, each point must be equipped with a substrate made of a dielectric material. And the distance of the wire from the wall should not be less than 10 mm. When choosing switches and sockets, preference should be given to those devices that are made of high-quality plastic and have a thick-walled body.

For hidden location

When arranging hidden wiring, the risks of mechanical damage are much lower. The mechanisms are installed inside the wall, the cables are "hidden" in specially prepared channels - strobes. Such work, of course, is more costly and time-consuming, but it more than pays off with reliability and compact appearance. A prerequisite for installing a modern switch or socket is a socket box, which is a round or rectangular plastic box.

Fixing the socket box on gypsum mortar

Fixing the socket box on gypsum mortar The socket box is fixed in the thickness of the wall with a cement or gypsum mortar. When installing, pay attention to the correct fit of the box, the edges of the socket box should not rise above the plane of the wall. So that during installation the solution does not get into the interior of the socket box, it is recommended to seal the holes with tape.

Established norms for location

At what level from the floor should sockets and switches be installed? There are significant disagreements among non-professionals on this subject, but the dispute is easily resolved if we turn to regulatory documents.

Installation height according to PUE

Rules for installing electrical appliances - the main document for guidance when installing a home network.

Excerpt from the Rules for the installation of electrical appliances

Excerpt from the Rules for the installation of electrical appliances Requirements for placement in accordance with GOST and SP

GOST R50571.11–96 focuses on the installation of switches and sockets in the bathroom at a distance of at least 60 cm from the shower door.

Location of sockets in bathrooms

Location of sockets in bathrooms In the Code of Rules (SP) 31-110-2003. the following information is provided.

Quote from Code of Practice 31–110–2003

Quote from Code of Practice 31–110–2003 Thus, it becomes clear that the installation height of sockets and switches in a residential area is not limited by strict rules.

Height according to the "European standard"

Strictly speaking, the term "European standard" is not a valid standard. Rather, it denotes a certain kind of design in which the placement of electrical equipment is carried out in a certain way. Moreover, in fact, this type of installation is of North American origin. But since today the lion's share of household appliances in our homes are imported, for the convenience of the outlet they are placed precisely according to the rules of the "European standard".

Parameters for the placement of electrical devices according to the "European standard"

Parameters for the placement of electrical devices according to the "European standard" This is also due to the fact that Western manufacturers produce their products with short power cords. For example, most refrigerators cannot be connected to a socket located 1 m above the floor. And using an extension cord is an additional cost and security risk. Switches, by American standards, are more convenient to place at a level of 90 cm from the floor. This allows you to control the lighting without raising your hands. Sockets are installed at a height of 30–40 cm from the floor. In addition, a horizontal distance of 180 cm is provided between the sockets.

The nuances of the requirements in various institutions.

Some organizations engaged in specific activities are prescribed individual rules for the placement of switches and sockets.

- In nurseries, kindergartens, schools and summer camps, the height of the switches is determined at a level of 1.8 m. The same level is also determined for sockets.

- At public catering and trade establishments, sockets are installed at a height of 1.3 m. Automatic switches - at a height of 1.3 - 1.6 m.

- It is forbidden to install light switches in potentially explosive buildings (including kitchens with gas stoves or water heaters).

Do-it-yourself installation height of switches and sockets in the apartment

Wiring in the kitchen

Sockets and switches in the living room and bedroom

- In the living room there is a socket for powering the TV at a height of 1.3 m from the floor. At the same level, it is customary to install a socket for connecting a router. Low-current cables of a computer network and a television antenna are also brought here.

Location of the socket block at a height of 1.3 m from the floor level

Location of the socket block at a height of 1.3 m from the floor level - Several outlets are placed near the desk. One block, consisting of 2 or 3 sockets, is placed at a level of 30 cm from the floor. And the second block - at a height of 15 cm from the level of the tabletop, for connecting a table lamp or charging a laptop (phone, tablet).

The socket block is installed on the open space of the wall

The socket block is installed on the open space of the wall - The main chandelier or spotlights on the ceiling are controlled by a switch located at the entrance to the living room. As a rule, a switch with several keys is installed here - this allows you to vary the intensity of lighting.

- The bedroom is equipped with one general switch at the entrance and two switches on both sides of the double bed. They also install an outlet there so that you can, without getting out of bed, put your phone on charge, connect an electronic alarm clock, etc. Convenient height - 0.7 m from the floor.

Sockets are installed at a height of 0.7 m from the floor

Sockets are installed at a height of 0.7 m from the floor

Electrical outlets in the bathroom

Due to high humidity and possible splashing, it is recommended to connect all sockets in the bathroom through an RCD. The distance from the washbasin and bathroom (shower cubicle) to the socket is less than 60 cm. It is prohibited.

- washing machine - 1 m.;

- water heating boiler - 1.8 m;

- additional power point for a razor or hair dryer - 1.1 m.

In the bathroom, it is recommended to install sockets with an IP 66 index

In the bathroom, it is recommended to install sockets with an IP 66 index Light switches are installed outside, at the entrance to the bathroom.

Video: sockets in the kitchen

Independent work on the replacement and transfer of "electric points" implies direct contact with high voltage currents. Even weak electrical shocks sometimes lead to cardiac arrest or cause nervous breakdowns. Before starting work, you need to turn off the power supply to the apartment.