The use of compressed natural gas. Natural gas as motor fuel

Gas that is extracted from the bowels of the earth or is a product of the processing of other hydrocarbons can subsequently be used in a liquefied or compressed form. What are the features of both options for the use of the respective fuel?

What is liquefied gas?

Under liquefied It is customary to understand natural gas, which is transferred from the initial, actually gaseous state into a liquid state - by cooling to a very low temperature, about minus 163 degrees Celsius. The volume of fuel is reduced by about 600 times.

Transportation of liquefied gas requires the use of special cryogenic tanks that are able to maintain the required temperature of the respective substance. The advantage of this type of fuel is the ability to deliver it to those places where it is problematic to lay conventional gas pipelines.

The conversion of liquefied gas to its original state also requires special infrastructure - regasification terminals. The processing cycle of the considered type of fuel - extraction, liquefaction, transportation and regasification - significantly increases the final cost of gas for the consumer.

The fuel in question is used, usually for the same purposes as natural gas in its original state - for heating rooms, ensuring the functioning of industrial equipment, power plants, as raw materials in some segments of the chemical industry.

What is compressed natural gas?

Under compressed, or compressed, it is customary to understand natural gas, which, like liquefied gas, is also presented in a liquid state, achieved, however, not by reducing the temperature of the fuel, but by increasing the pressure in the container in which it is placed. The volume of compressed gas is about 200 times less than that of the fuel in its original state.

Converting natural gas to liquid using high pressure is generally cheaper than liquefying fuel by lowering its temperature. The transportation of the considered type of gas is carried out in containers, as a rule, less technologically complex than cryocisters. Regasification of the corresponding type of fuel is not required: since it is under high pressure, it is easy to remove it from the tanks - it is enough to open the valves on them. Therefore, the cost of compressed gas for the consumer is in most cases lower than that which characterizes liquefied fuel.

Compressed gas is most often used as a fuel in various vehicles - cars, locomotives, ships, gas turbine engines of aircraft.

Comparison

The main difference between liquefied gas and compressed gas is that the first type of fuel is obtained by lowering the temperature of the initial gaseous substance, which is accompanied by its transformation into a liquid. Compressed gas is also a liquid fuel, but it is obtained by placing it in a container under high pressure. In the first case, the initial volume of gas exceeds the processed one (transferred to liquid) by about 600 times, in the second case, by 200 times.

It should be noted that liquefied gas is most often obtained by processing "classical" natural gas, which is represented mainly by methane. Compressed fuels are also made from many other naturally occurring gases such as propane or butane.

Having determined the difference between liquefied and compressed gas, we will reflect the conclusions in the table.

Table

| Liquefied gas | compressed gas |

| What do they have in common? | |

| To obtain both types of fuel, the same raw material is used - natural gas (methane is most often used to produce liquefied gas, propane, butane and other gases are also used to produce compressed gas) | |

| What is the difference between them? | |

| Obtained by lowering the temperature of the original fuel - natural gas | It is obtained by increasing the pressure in the tank in which the source natural gas is placed. |

| Requires the use of high-tech cryo-tanks for storage and movement | For storage and movement requires the use of relatively less technologically sealed containers |

| The volume of the original fuel is approximately 600 times greater than that converted to liquefied gas | The volume of the original fuel is approximately 200 times greater than that converted into compressed gas |

| It is used, as a rule, for the same purposes as ordinary natural gas - for space heating, ensuring the operation of industrial equipment, power plants | It is usually used as fuel for vehicles |

Natural gas, the main part of which is methane (92-98%), is by far the most promising alternative fuel for cars. Natural gas can be used as fuel both in compressed (compressed) and liquefied form.

Methane- the simplest hydrocarbon, a colorless gas (under normal conditions) odorless, the chemical formula is CH4. Slightly soluble in water, lighter than air. When used in everyday life, industry, odorants (usually thiols) with a specific "gas smell" are usually added to methane. Methane is non-toxic and harmless to human health.

Extraction and transportation

The gas is located in the bowels of the Earth at a depth of one to several kilometers. Before the start of gas production, it is necessary to carry out geological exploration work, which allows to establish the location of deposits. Gas is produced using wells specially drilled for this purpose in one of the possible ways. Most often, gas is transported through gas pipelines. The total length of gas distribution pipelines in Russia is more than 632 thousand kilometers - this distance is almost 20 times the circumference of the Earth. The length of main gas pipelines in Russia is 162,000 kilometers.

Use of natural gas

The scope of natural gas is quite wide: it is used for space heating, cooking, heating water, the production of paints, glue, acetic acid and fertilizers. In addition, natural gas in compressed or liquefied form can be used as a motor fuel in vehicles, special and agricultural machinery, railway and water transport.

Natural gas - environmentally friendly motor fuel

90% of air pollution comes from vehicles.

Transfer of transport to environmentally friendly motor fuel - natural gas - allows to reduce emissions of soot, highly toxic aromatic hydrocarbons, carbon monoxide, unsaturated hydrocarbons and nitrogen oxides into the atmosphere.

When burning 1000 liters of liquid petroleum motor fuel, 180-300 kg of carbon monoxide, 20-40 kg of hydrocarbons, 25-45 kg of nitrogen oxides are emitted into the air together with exhaust gases. When natural gas is used instead of petroleum fuel, the release of toxic substances into the environment is reduced by approximately 2-3 times for carbon monoxide, for nitrogen oxides - 2 times, for hydrocarbons - 3 times, for smoke - 9 times, and the formation of soot, characteristic of diesel engines is absent.

Natural gas - economical motor fuel

Natural gas is the most economical motor fuel. Its processing requires minimal costs. In fact, all that needs to be done with gas before refueling a car is to compress it in a compressor. Today, the average retail price of 1 cubic meter of methane (which in terms of its energy properties is equal to 1 liter of gasoline) is 13 rubles. This is 2-3 times cheaper than gasoline or diesel fuel.

Natural gas is a safe motor fuel

The concentration* and temperature** flammability limits of natural gas are significantly higher than those of gasoline and diesel fuel. Methane is twice as light as air and quickly dissolves into the atmosphere when released.

According to the “Classification of combustible substances according to the degree of sensitivity” of the Ministry of Emergency Situations of Russia, compressed natural gas is classified as the safest, fourth class, and propane-butane - to the second.

* The formation of an explosive concentration occurs when the content of gas vapor in the air is from 5% to 15%. In open space, the formation of an explosive mixture does not occur.

** The lower self-ignition limit of methane is 650°C.

Natural gas - technologically advanced motor fuel

Natural gas does not form deposits in the fuel system, does not wash off the oil film from the cylinder walls, thereby reducing friction and reducing

engine wear.

The combustion of natural gas does not produce solid particles and ash, which cause increased wear of engine cylinders and pistons

Thus, the use of natural gas as a motor fuel makes it possible to increase the service life of the engine by 1.5-2 times.

The table below summarizes a few facts about CNG and LNG:

It is cheaper than traditional fuels, and the greenhouse effect caused by its combustion products is less compared to conventional fuels, so it is safer for the environment. Compressed natural gas is produced by compressing (compressing) natural gas in compressor units. Storage and transportation of compressed natural gas takes place in special gas accumulators under a pressure of 200-220 bar. The addition of biogas to compressed natural gas is also used, which reduces carbon emissions into the atmosphere.

Compressed natural gas as a fuel has a number of advantages:

- Methane (the main component of natural gas) is lighter than air and in the event of an accidental spill it evaporates quickly, unlike the heavier propane that accumulates in natural and artificial depressions and creates an explosion hazard.

- Non-toxic in low concentrations;

- Does not cause corrosion of metals.

- Compressed natural gas is cheaper than any petroleum fuel, including diesel, but surpasses them in terms of calorific value.

- The low boiling point guarantees complete evaporation of natural gas at the lowest ambient temperatures.

- Natural gas burns almost completely and does not leave soot, which worsens the environment and reduces efficiency. The removed flue gases do not contain sulfur impurities and do not destroy the metal of the chimney.

- Operating costs for maintenance of gas boilers are also lower than traditional ones.

Another feature of compressed natural gas is that boilers running on natural gas have a higher efficiency - up to 94%, do not require fuel consumption for preheating it in winter (like oil and propane-butane).

Wikimedia Foundation. 2010 .

See what "Compressed natural gas" is in other dictionaries:

Natural gas compressed- Compressed natural gas (CNG) natural gas (compressed). CNG produced at CNG stations must comply with GOST 27577 2000... Source: Rules for the technical operation of CNG filling compressor stations. VRD 39 2.5 082… … Official terminology

Fuel is a substance from which thermal energy can be obtained with the help of a certain reaction. Contents 1 The concept of fuel 2 The main modern types of fuel ... Wikipedia

Fuel is a substance or mixture of substances capable of exothermic chemical reactions with an oxidizer external or contained in the fuel itself, used to release energy, initially thermal. Fuel that does not contain an oxidizing agent ... Wikipedia

KKE is an abbreviation for a number of political parties: the Communist Party of Germany in 1918-1946. Communist Party active in West Germany in 1948-1969. Communist Party of Greece Communist Party of Holland ... ... Wikipedia

gas engines- engines that convert the chemical energy of gas fuel into useful (mechanical, chemical, thermal) energy. The first internal combustion engine, in which light gas was used as a motor fuel, was designed ... ... Oil and gas microencyclopedia

Fuels commonly used to power the engine: gasoline, liquefied petroleum gas (LPG), compressed natural gas (CNG), gasoline or LPG, gasoline or CNG, diesel fuel. [GOST R 41.83 2004] Topics motor vehicles EN fuel… … Technical Translator's Handbook

fuel needed for engines 2.18 fuel requirement by the engine fuel commonly used to power an engine: gasoline, liquefied petroleum gas (LPG), compressed natural gas (CNG), gasoline or LPG, gasoline or CNG, diesel ... ...

GOST R 41.83-2004: Uniform provisions concerning the certification of vehicles with regard to emissions of harmful substances depending on the fuel required for engines- Terminology GOST R 41.83 2004: Uniform regulations regarding the certification of vehicles with regard to emissions of harmful substances depending on the fuel required for engines original document: 2.13 OBD (OBD): Onboard ... ... Dictionary-reference book of terms of normative and technical documentation

Coordinates: 55°52′24″ s. sh. 37°28′34″ E / 55.873333° N sh. 37.476111° E etc. ... Wikipedia

KKE- CNG Compressed Natural Gas Communist Party of Greece Greece, polit. Dictionary: S. Fadeev. Dictionary of abbreviations of the modern Russian language. S. Pb.: Politekhnika, 1997. 527 p. CNG container point cargo … Dictionary of abbreviations and abbreviations

In production processes associated with the use of gases (dispersion, mixing, pneumatic transport, drying, absorption, etc.), the movement and compression of the latter occurs due to the energy imparted to them by machines that bear the general name compression. At the same time, the productivity of compression plants can reach tens of thousands of cubic meters per hour, and the pressure varies within 10–8–10 3 atm., which leads to a wide variety of types and designs of machines used to move, compress and rarefy gases. Machines designed to create elevated pressures are called compressors, and machines that work to create a vacuum are called vacuum pumps.

Compression machines are classified mainly according to two criteria: the principle of operation and the degree of compression. Compression ratio is the ratio of the final gas pressure at the outlet of the machine R 2 to initial inlet pressure p 1 (i.e. p 2 /p 1).

According to the principle of operation, compression machines are divided into piston, bladed (centrifugal and axial), rotary and jet.

According to the degree of compression, they distinguish:

– compressors used to create high pressures, with a compression ratio R 2 /R 1 > 3;

- gas blowers used to move gases with high resistance of the gas pipeline network, while 3 > p 2 /p 1 >1,15;

- fans used to move large quantities of gas at p 2 /p 1 < 1,15;

- vacuum pumps that suck gas from a space with low pressure (below atmospheric) and pump it into a space with high (above atmospheric) or atmospheric pressure.

Any compression machines can be used as vacuum pumps; a deeper vacuum is created by reciprocating and rotary machines.

Unlike dropping liquids, the physical properties of gases are functionally dependent on temperature and pressure; the processes of movement and compression of gases are associated with internal thermodynamic processes. At low pressure and temperature differences, changes in the physical properties of gases during their movement at low velocities and pressures close to atmospheric are insignificant. This makes it possible to use all the basic provisions and laws of hydraulics to describe them. However, when deviating from normal conditions, especially at high degrees of gas compression, many positions of the hydraulics undergo a change.

Thermodynamic foundations of the gas compression process

The effect of temperature on the change in gas volume at constant pressure, as is known, is determined by the Gay-Lussac law, i.e., at p= const the volume of a gas is directly proportional to its temperature:

where V 1 and V 2 - gas volumes, respectively, at temperatures T 1 and T 2 expressed on the Kelvin scale.

The relationship between gas volumes at different temperatures can be represented by the relationship

, (4.1)

, (4.1)

where V and V 0 - final and initial volumes of gas, m 3; t and t 0 – final and initial gas temperature, °С;β t– relative coefficient of volumetric expansion, deg. -one .

Change in gas pressure depending on temperature:

, (4.2)

, (4.2)

where R and R 0 – final and initial gas pressure, Pa;β R– relative temperature coefficient of pressure, deg. -one .

Mass of gas M remains constant as the volume changes. If ρ 1 and ρ 2 are the densities of two temperature states of the gas, then  and

and  or

or  , i.e. The density of a gas at constant pressure is inversely proportional to its absolute temperature.

, i.e. The density of a gas at constant pressure is inversely proportional to its absolute temperature.

According to the Boyle-Mariotte law, at the same temperature, the product of the specific volume of gas v on the value of its pressure R is a constant value pv= const. Therefore, at constant temperature  , a

, a  , i.e., the density of the gas is directly proportional to the pressure, since

, i.e., the density of the gas is directly proportional to the pressure, since  .

.

Given the Gay-Lussac equation, one can obtain a relation relating the three parameters of a gas: pressure, specific volume, and its absolute temperature:

. (4.3)

. (4.3)

The last equation is called Claiperon's equations. In general:

or

or  , (4.4)

, (4.4)

where R is the gas constant, which is the work done by a unit mass of an ideal gas in isobaric ( p= const) process; when the temperature changes by 1°, the gas constant R has the dimension of J/(kgdeg):

, (4.5)

, (4.5)

where l R is the specific work of volume change performed by 1 kg of ideal gas at constant pressure, J/kg.

Thus, equation (4.4) characterizes the state of an ideal gas. At a gas pressure over 10 atm, the use of this expression introduces an error in the calculations ( pv≠RT), therefore it is recommended to use formulas that more accurately describe the relationship between pressure, volume and temperature of a real gas. For example, the van der Waals equation:

, (4.6)

, (4.6)

where R= 8314/M– gas constant, J/(kg K); M is the molecular weight of the gas, kg/kmol; a and in - quantities that are constant for a given gas.

Quantities a and in can be calculated from the critical gas parameters ( T kr and R cr):

;

; . (4.7)

. (4.7)

At high pressures, the value a/v 2 (additional pressure in the van der Waals equation) is small compared to the pressure p and it can be neglected, then equation (4.6) turns into the equation of state of a real Dupré gas:

, (4.8)

, (4.8)

where the value in depends only on the type of gas and is independent of temperature and pressure.

In practice, to determine the parameters of a gas in its various states, thermodynamic diagrams are more often used: T–S(temperature–entropy), p–i(dependence of pressure on enthalpy), p–V(dependence of pressure on volume).

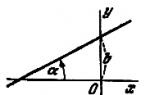

Figure 4.1 - T–S diagram

On the diagram T–S(Fig. 4.1) line AKV represents a boundary curve that divides the diagram into separate regions corresponding to certain phase states of a substance. The area located to the left of the boundary curve is the liquid phase, to the right is the area of dry vapor (gas). In the area bounded by the curve ABK and the abscissa axis, two phases coexist simultaneously - liquid and vapor. Line AK corresponds to the complete condensation of steam, here the degree of dryness x= 0. Line KV corresponds to complete evaporation, x = 1. The maximum of the curve corresponds to the critical point K where all three states of matter are possible. In addition to the boundary curve, lines of constant temperatures (isotherms, T= const) and entropy ( S= const), directed parallel to the coordinate axes, isobars ( p= const), constant enthalpy lines ( i= const). The isobars in the wet steam region are directed in the same way as the isotherms; in the region of superheated vapor, they change direction steeply upwards. In the region of the liquid phase, the isobars almost merge with the boundary curve, since liquids are practically incompressible.All gas parameters on the diagram T–S referred to 1 kg of gas.

Since according to the thermodynamic definition  , then the heat of change in the state of the gas

, then the heat of change in the state of the gas  . Therefore, the area under the curve describing the change in the state of the gas is numerically equal to the energy (heat) of the change in state.

. Therefore, the area under the curve describing the change in the state of the gas is numerically equal to the energy (heat) of the change in state.

The process of changing the parameters of a gas is called the process of changing its state. Each state of the gas is characterized by the parameters p,v and T. In the process of changing the state of the gas, all parameters can change or one of them remains constant. Thus, a process occurring at constant volume is called isochoric, at constant pressure - isobaric, and at constant temperature isothermal. When, in the absence of heat exchange between the gas and the environment (heat is neither removed nor supplied), all three parameters of the gas change ( p,v,T) in expansion or contraction process , the process is called adiabatic, and when the change in gas parameters occurs with a continuous supply or removal of heat – polytropic.

With changing pressure and volume, depending on the nature of heat exchange with the environment, the change in the state of the gas in compression machines can occur isothermally, adiabatically and polytropically.

At isothermal process, the change in the state of the gas follows the Boyle–Mariotte law:

pv= const.

On the diagram p–v this process is depicted by a hyperbola (Fig. 4.2). Work 1 kg of gas l graphically represented by the shaded area, which is equal to  , i.e.

, i.e.

or

or  . (4.9)

. (4.9)

The amount of heat that is released during isothermal compression of 1 kg of gas and that must be removed by cooling so that the temperature of the gas remains constant:

, (4.10)

, (4.10)

where c v and c R are the specific heat capacities of the gas at constant volume and pressure, respectively.

On the diagram T–S process of isothermal compression of gas from pressure R 1 to pressure R 2 is shown as a straight line ab drawn between isobars R 1 and R 2 (Fig. 4.3).

|

|

|

|

Figure 4.2 - The process of isothermal gas compression on the diagram |

Figure 4.3 - The process of isothermal gas compression on the diagram T–S |

The heat equivalent to the work of compression is represented by the area bounded by the extreme ordinates and the straight line ab, i.e.

.

(4.11)

.

(4.11)

Figure 4.4 - Gas compression processes in the diagram  :

:

A is an adiabatic process;

B - isothermal process

Since the expression for determining the work expended in the isothermal compression process includes only volume and pressure, then within the limits of applicability of equation (4.4) it does not matter which gas will be compressed. In other words, the isothermal compression of 1 m 3 of any gas at the same initial and final pressures consumes the same amount of mechanical energy.At adiabatic In the process of gas compression, a change in its state occurs due to a change in its internal energy, and, consequently, in temperature.

In general form, the equation of an adiabatic process is described by the expression:

,

(4.12)

,

(4.12)

where  is the adiabatic index.

is the adiabatic index.

Graphically (Fig. 4.4) this process on the diagram p–v is depicted as a steeper hyperbola than in Fig. 4.2., since k> 1.

If accept

, then

, then  .

(4.13)

.

(4.13)

Because the  and R= const, the resulting equation can be expressed differently:

and R= const, the resulting equation can be expressed differently:

or

or  .

(4.14)

.

(4.14)

By appropriate transformations, one can obtain dependencies for other gas parameters:

;

; . (4.15)

. (4.15)

Thus, the gas temperature at the end of its adiabatic compression

. (4.16)

. (4.16)

The work done by 1 kg of gas in an adiabatic process:

. (4.17)

. (4.17)

The heat released during adiabatic compression of a gas is equivalent to the work expended:

Taking into account relations (4.15), the work on gas compression in the adiabatic process

. (4.19)

. (4.19)

The process of adiabatic compression is characterized by the complete absence of heat exchange between the gas and the environment, i.e. dQ = 0, and dS = dQ/T, that's why dS = 0.

Thus, the process of adiabatic gas compression proceeds at a constant entropy ( S= const). On the diagram T–S this process is represented by a straight line AB(Fig. 4.5).

Figure 4.5 - Image of gas compression processes on the diagram T–S

If during compression the released heat is taken away in a smaller amount than is necessary for an isothermal process (which occurs in all real compression processes), then the actual work expended will be greater than during isothermal compression, and less than during adiabatic:

, (4.20)

, (4.20)

where m is the polytropic index, k>m>1 (for air m  ).

).

The value of the polytropic index m depends on the nature of the gas and the conditions of heat exchange with the environment. In compression machines without cooling, the polytropic exponent can be greater than the adiabatic exponent ( m>k), i.e., the process in this case proceeds along the superadiabatic.

The work expended on the rarefaction of gases is calculated using the same equations as the work on compressing gases. The only difference is that R 1 will be less than atmospheric pressure.

Polytropic compression process pressure gas R 1 up to pressure R 2 in fig. 4.5 will be depicted straight AC. The amount of heat released during polytropic compression of 1 kg of gas is numerically equal to the specific work of compression:

Gas compression end temperature

. (4.22)

. (4.22)

Power, spent by compression machines for compression and rarefaction of gases, depends on their performance, design features, heat exchange with the environment.

Theoretical power expended on gas compression  , is determined by the productivity and specific work of compression:

, is determined by the productivity and specific work of compression:

, (4.23)

, (4.23)

where G and V- mass and volumetric productivity of the machine, respectively;  is the density of the gas.

is the density of the gas.

Therefore, for various compression processes, the theoretical power input is:

;

(4.24)

;

(4.24)

; (4.25)

; (4.25)

, (4.26)

, (4.26)

where  - volumetric performance of the compression machine, reduced to suction conditions.

- volumetric performance of the compression machine, reduced to suction conditions.

The actual power expended is greater for a number of reasons; the energy consumed by the machine is higher than that which it transfers to the gas.

To evaluate the effectiveness of compression machines, a comparison of this machine with the most economical machine of the same class is used.

Refrigerated machines are compared to machines that would compress the gas isothermally under given conditions. In this case, the efficiency is called isothermal, from:

, (4.27)

, (4.27)

where N- the actual power expended by this machine.

If the machines operate without cooling, then the gas compression in them occurs along a polytrope, the exponent of which is higher than the adiabatic exponent ( m k). Therefore, the power expended in such machines is compared with the power that the machine would expend in the adiabatic compression of the gas. The ratio of these powers is the adiabatic efficiency:

.

(4.28)

.

(4.28)

Taking into account the power lost to mechanical friction in the machine and taken into account by the mechanical efficiency. – fur, power on the shaft of the compression machine:

or

or  . (4.29)

. (4.29)

Engine power is calculated taking into account efficiency. the engine itself and efficiency. transfers:

. (4.30)

. (4.30)

The installed power of the engine is taken with a margin (  ):

):

. (4.31)

. (4.31)

The value of hell ranges from 0.930.97; out depending on the degree of compression has a value of 0.640.78; mechanical efficiency varies within 0.850.95.

One and the same fact can be viewed from at least three points of view. So, the use of compressed natural gas in transport as a fuel can be said to be the lot of the poor and even the poor, but it can be said that this is the choice of those who are economical and not used to wasting money in vain, and there is also an opinion that methane is the fuel of the future and those those who are now switching to it simply keep up with the times and ride the wave of the close and promising mainstream. How to count - the choice is yours!

The search for alternative sources of automotive fuel is a problem that has received the closest attention in recent years. The rise in oil prices, energy carriers, the tightening of environmental requirements, the savings in fuel and lubricants - all this has become the main driving force in the search for alternative fuels for many countries. In the last decade of the 20th century, the third wave of popularity of natural gas used as a motor fuel began to gain momentum in the world economy.

Experts predict that this wave will reach its peak by the end of the first quarter of the 21st century.

Natural gas

Natural gas, which is more than 90% methane, is now available almost all over the world. And then what to say about Russia!

According to experts, the use of natural gas is less affected by economic crises, which cannot be said about the market for oil and oil products. Methane, whether it is fossil natural gas or biomethane, can be distributed through both the existing natural gas network and the already existing filling network. True, in some countries on the threshold of the industrial revolution, the issue of distribution networks has not yet been resolved. Methane required for road transport can be supplied to the consumer:

■ through the international gas pipeline network;

■ in the form of liquefied natural gas using tankers, road or rail tankers;

■ through local low pressure pipelines (biomethane);

■ tank trucks (liquefied biomethane).

At present, international standards have been adopted and the main types of vehicles suitable for the delivery of methane have been approved, and in most regions there are already certified suppliers of complete gas equipment for its use in cars.

Undeniable advantages

Converting cars to natural gas does not require engine modifications and can significantly improve the environment, as the emission of toxic substances into the atmosphere is reduced.

Thus, emissions of carbon monoxide are reduced by 5-10 times, hydrocarbons - by 3 times, nitrogen oxides - by 1.5-2.5 times. The noise level of a running engine is reduced by 2 times. The operation of the engine on compressed gas becomes softer, detonation does not occur in any mode, the octane number of the gas is 110. In addition, methane is lighter than air and immediately evaporates when it leaks, without creating an explosive mixture.

The use of gas fuel increases the service life of the engine and engine oil by 2 times, and spark plugs - by 40%. With the same consumption per 100 km of track, the cost of gas is 2–3 times lower than the cost of gasoline or diesel fuel, which restrains the growth of tariffs for transport services. The use of natural gas as a motor fuel reduces the dependence of transport on oil and oil products and releases a significant part of them for use in areas where they have no alternative. We note right away that further we will only talk about natural gas (methane: compressed or liquefied), and not about the propane-butane mixture, which is widely used in everyday life, as well as used in transport (the so-called liquefied hydrocarbon gas).

Compressed or liquefied

Liquefied natural gas (LNG, English LNG - liquefied natural gas) is obtained by cooling natural gas methane to -162 ° C. In the liquid state, the volume of gas is reduced by a factor of 600, which makes it possible to significantly increase the efficiency of its storage and transportation. Liquefied natural gas is transported in the same way as oil, in special tankers. In importing countries, it is stored in tanks. In special terminals, LNG is heated, due to which it returns to a gaseous state, and after that it is pumped into the gas transmission system. Compressed, or compressed natural gas (CNG English CNG - compressed natural gas) is the same methane, but in a gaseous state, under pressure up to 20 MPa. The consumer can immediately use this gas for his own needs. Experts continue to argue about the advantages and disadvantages of compressed and liquefied natural gas. Some believe that over time, when the necessary conditions are created, liquefied natural gas will displace compressed natural gas, but others do not think so. Table 1 shows a comparative characteristic of liquefied natural gas and compressed, compressed.

It can be seen that CNG does not require special transport devices for delivery from the manufacturer, however, when using it, it is necessary to use special cylinders that are expensive and heavy. As for the price of such fuel, in Russia the cost of a cubic meter of compressed gas is set by law - in the amount of 50% of the cost of a liter of AI76 gasoline. According to this position, CNG significantly outperforms liquefied petroleum gas, for which the price is dictated by the market. However, it loses in terms of the cost of cylinders and equipment.

LNG abroad

Despite all the difficulties, abroad, in parallel with the use of CNG, the use of methane in vehicles and liquefied natural gas is expanding, this is especially indicative of the United States. Thus, a wide network of filling stations has been created in the southwestern United States in the states of California, Arizona, Colorado, Texas, Pennsylvania and others. Large automotive corporations such as Mack, Ford, MAN pay the most serious attention to this issue. In Europe, the production of vehicles running on liquefied natural gas is carried out by such companies as MercedesBenz, MAN, BMW, etc. Liquefied gas as a motor fuel has been used in Belgium, Finland, Germany, the Netherlands, Norway, France, Spain, Great Britain and other countries Europe.

CNG in the CIS

Today, in Russia, CNG has become more widespread in the automotive sector, especially for urban and municipal transport. In recent years, attempts have been made to expand the use of this type of fuel. State organizations and private companies are involved in solving this problem. There is already a long-term experience in the operation of CNG-powered automotive gas equipment, especially in the structure of OAO Gazprom.

In 2001, the CIS Economic Council proposed for implementation the interstate program "Use of natural gas as a motor fuel for motor vehicles for 2001-2005", and partly due to it in Russia, and in the CIS countries, CNG (compressed methane) is most widely used. rather than liquefied natural gas.

CNG cylinders

To replace one liter of diesel fuel with the same amount of energy contained in gasoline, a fuel tank with a volume of 15% more is required. If you use LNG, then the volume of the tank will have to be increased by 70%, and when using compressed natural gas (methane), which is stored at an operating pressure of 200 bar (20 MPa), the fuel tanks must take up 4.5 times more volume.

Therefore, the use of compressed natural gas is largely limited by the availability of special cylinders. Unlike other SGB countries in Russia, this issue is being resolved quite successfully. Cylinders for methane, as a rule, have a cylindrical shape and are conditionally divided into four types, including both cylinders traditionally made of steel, and a lightweight version - cylinders using polymer composite materials based on glass carbon or organic fibers. These containers include:

■ seamless steel cylinders;

■ metal-plastic cylinders (type 1), consisting of a metal thick-walled shell (liner) bearing the main load, and an outer reinforcing shell made of a polymer composite material;

■ metal-plastic cylinders (type 2) - a thin-walled metal liner and a reinforcing shell made of a polymer composite material of the "cocoon" type over the entire surface;

■ Composite cylinders - a polymer liner with embedded metal elements for attaching shut-off equipment and a load-bearing shell made of composite material.

In Russia, there are 4 manufacturers of cylinders for compressed natural gas (designed for a pressure of 20 MPa), two of them produce both all-metal and metal-plastic cylinders (see table 2).

Companies such as Ruzhkhimmash (Ruzaevka, Mordovia) and Orgenergogaz (a division of Gazprom), which produced these products, stopped producing automobile cylinders. Small batches are produced by NPP "Mashtest" (Korolev).

There are a couple of manufacturers of automotive CNG cylinders in Ukraine.

These are OAO "Berdichevsky Machine-Building Plant Progress" and OAO "Mariupol Metallurgical Plant named after. Ilyich. In conditions of good demand for CNG and a developed network of gas filling stations in Ukraine, manufacturers note a good demand for their products.

Almost all Russian manufacturers of cylinders are focused on the domestic market and the market of the CIS countries, although the plant in Orsk has received an international certificate and is able to supply these products to non-CIS countries.

World practice shows that about 70–80% of the cylinders used for transporting methane are all-metal. And this is despite the fact that the use of metal-plastic cylinders makes it possible to reduce the weight of the kit by about 1.3–1.5 times, which is especially important when it is necessary to install several cylinders. This is due to the fact that effective technologies for the production of "composite" cylinders appeared much later and, of course, to the fact that metal-plastic cylinders are more expensive than all-metal ones. However, it should be noted that the use of lightweight cylinders in the long run is more profitable due to the weight savings of the machine, leading to fuel savings, and an increase in the carrying capacity of the vehicle - the latter is especially important when we are talking about freight transport.

HBO - gas equipment

In addition to the cylinders themselves, for their installation on a vehicle, it is necessary to purchase additionally appropriate gas-balloon equipment (GBO). The owner of the vehicle has two options - to buy domestic HBO (produced by the Ryazan Automobile Equipment Plant, Votkinsk Gas Equipment Plant, etc.) or imported.

Issue price

Converting a car to run on CNG is not cheap. Thus, the cost of a metal-composite cylinder is about 7.5–8.5 dollars/l, an all-metal one - 7 dollars/l. Thus, a serial metal-composite cylinder with a volume of 50 liters will cost the consumer $400, an all-metal one - $350, and this is without taking into account the cost of gas-balloon equipment. If it is planned to convert trucks or buses to CNG, then, depending on the required volume, several cylinders will have to be installed, which will lead to a several-fold increase in the cost of the kit. Converting a passenger car to CNG will cost $1,000, while a truck and buses will cost more than $2,000-2,500.

The cost of automobile cylinders of the CIS countries for 50 liters for liquefied hydrocarbon gas (propane-butane mixture) is 30-50 dollars, and the cost of re-equipping a car will be about 200-400 dollars, depending on the manufacturer and type of HBO.

Payback

According to experts, taking into account fuel prices at the beginning of 2006, the payback period for motor vehicles when switching from gasoline to compressed gas, with an average annual mileage of 60,000 km, is from 3 to 5 years, depending on the carrying capacity and type of vehicle. If we take into account the increased cost of gasoline since the beginning of the year and the greater mileage of the car, then the payback period may be significantly shorter. If we take auto-tractor equipment, for example, K700 or T150, then due to the impressive fuel consumption, the payback period will be about a year.

It becomes clear why in Western countries and in our capital urban transport is primarily switched to alternative gas fuel - the savings are too obvious and great.

World experience

By the end of 2005, there were over 4.6 million CNG vehicles in the world. The undoubted leaders among the countries in this area are Argentina, Brazil and Pakistan. The first two countries have a fleet of gas-cylinder vehicles (GBV) over one million.

CNG filling stations

Modern CNG filling stations must meet the following requirements:

■ low cost;

■ minimum dimensions and weight;

■ ease of installation and operation;

■ independence from power and heat supply systems;

■ maximum safety and comfort of working conditions for service personnel;

■ station control automation;

■ Efficiency of refueling with an accuracy sufficient for custody transfer (up to 2%).

Manufacturers must be ready to offer the customer a sufficient range of CNG filling stations in terms of performance.

Argentina and Brazil have a well-developed system of CNG filling stations (CNG). By the beginning of 2006, the number of CNG filling stations operating in these countries exceeded one thousand, which allowed Argentina to sell about 280 million cubic meters. m. of gas per month, and Brazil - about 163 million cubic meters. It is noteworthy that the highest rates in the construction of new CNG filling stations were noted in Pakistan and China, where the construction of more than 200 stations is planned. Over 100 CNG filling stations are being built in Brazil and Iran, but Argentina, the leader in the number of vehicles running on gas, does not plan to build new CNG filling stations.

Russia and CIS

Despite significant reserves of natural gas, Russia is still inferior to Ukraine in the use of CNG and occupies 12th place in the world ranking (see Table 3).

The Russian fleet of vehicles running on methane is estimated at about 52,000. Today in Russia there are 215 CNG filling compressor stations, 87% of which belong to Gazprom, their total design capacity is

is about 2 billion cubic meters. m / year, which would allow refueling 250 thousand cars a year. In 2005 Russian CNG filling stations sold 237 million cubic meters. m of natural gas (19.75 million cubic meters/month).

Thus, the loading of existing gas filling stations in Russia is only 10-15%, but in general, in recent years, the consumption of natural gas by road transport in Russia has been steadily growing by 25-30% per year.

Douglas Consulting, a company that not only sells NGV fuel, but also offers a full range of services for converting cars to natural gas, has also created its own network of multi-fuel filling complexes (MFPs) in Russia. In recent years, other oil and gas companies have also taken notice of CNG. Owing to Gazprom's policy, the gasification schemes of the regions obligatorily provide for the construction of CNG filling stations, and entire industries are gradually being converted to gas. For example, Russian Railways is successfully implementing a program to convert mainline and shunting diesel locomotives to gas.

A similar program for the gasification of agricultural machinery is being prepared. The program "Energy Strategy of Russia for the period up to 2020" indicates that in the coming years the consumption of motor fuel will grow most dynamically - by 15-26% by 2010 and by 33-55% by 2020. At the same time, liquefied and compressed natural gas will be used as a motor fuel in the long term, along with traditional liquid petroleum products (in the equivalent of up to 5 million tons of petroleum products by 2010 and up to 10–12 million tons in 2020).

In Tatarstan, the Russian oil region, there are 9 gas filling compressor stations of Tattransgaz LLC with a total capacity of 70.6 million cubic meters. m per year, while their actual loading is on average 7–8% of the design capacity due to the small number of gas-cylinder vehicles. In 2006–2010 OOO Tattransgaz plans to put into operation 11 more CNG filling stations. In addition, dozens of gas distribution stations operate in the republic, which, after additional installation of filling compressor modules, can provide a significant amount of compressed natural gas for refueling vehicles. Thus, the KKE in Russia has good prospects.

Ukraine

By the end of 2005, there were about 67,000 LPG vehicles and 147 CNG filling stations in Ukraine. CNG sales reached 540 million cubic meters. m/year. Initially, most CNG filling stations were run by Ukravtogaz, but then independent operators began to appear. However, despite the convincing advantages, the full potential of CNG has not yet been realized. According to the estimates of the structures working in the gas sector, Ukraine can re-equip 20-25 thousand vehicles annually.

Experts believe that one of the probable reasons for the lag is the lack of modern production of metal-composite cylinders in Ukraine. The two manufacturers mentioned earlier supply only all-metal cylinders to the domestic market, and they still cannot fully satisfy the needs of the market.

Among the tasks that need to be solved, there is also the development of the GZS network, support of the state and municipal authorities in this area.

Armenia

According to the Armenian Ministry of Transport, about 38,000 cars are currently equipped with gas installations, which is from 20 to 30% of cars operated in the country - a rather high figure. The reason for the sharp increase in the use of CNG is the significant difference between the prices of compressed natural gas and traditional automotive fuels. According to forecasts, the high growth rates of the transition of cars to gas in this country will continue in the coming years, moreover, they can reach 20-30% per year.

Other members of the commonwealth

Tajikistan is experiencing a significant increase in the consumption of natural gas by road transport. Starting from 1997, after the issuance of the corresponding decree of the government of the country, the number of CNG filling stations increased by 2006 from 3 to 53. Basically, these stations are not of high productivity. To date, the network of CNG stations in Belarus consists of 24 CNG stations in 17 cities of the republic, 5 mobile gas filling stations. Serviced park - 5.5 thousand LPG vehicles. OJSC Beltransgaz has developed a strategy for expanding the use of CNG, based on the national program for expanding the use of gas as a motor fuel, and a concept for the development of the CNG filling station network. By 2010, it is planned to increase the number of LPG to 14.5 thousand and the volume of CNG sales to 72.3 million cubic meters. m/year.

In Moldova and Uzbekistan, the transition of vehicles to compressed natural and liquefied gas is not so fast. So, in Moldova there are about 4.5 thousand GVAs and only 8 CNG filling stations. In Uzbekistan, less than 10 thousand units of vehicles running on gas fuel are operated (less than 1% of the entire vehicle fleet), about 30.0 thousand tons of liquefied hydrocarbon gas and 70–72 million cubic meters are used. m CNG, although natural resources can significantly increase the amount of HBA.

Brake for CNG

According to market analysts, there are problems hindering a wider transition to CNG. The main ones are:

■ the high cost of re-equipping vehicles to run on gas and often the lack of the necessary funds for these purposes from households, utilities, etc.;

■ Lack of mass production of finished LPG vehicles by Russian automakers;

■ underdeveloped network of CNG filling stations. In European countries, filling points are located at a maximum distance of 30 km from each other, and in the Russian Federation there are routes where there is not a single CNG filling station for thousands of kilometers.

In addition, it is necessary to solve the issues of a high degree of depreciation (especially in terms of the engine reserve) of the vehicle fleet of municipal property and government agencies, and the unpreparedness of personnel in many regions of the Russian Federation to service vehicles running on CNG. In Russia, there is a limited number of companies that have certificates and are able to convert vehicles to work on CNG, to inspect a vehicle with LPG in a timely manner. This problem is especially relevant for the regions.

The transfer of transport to natural gas is undoubtedly an important task and, with a reasonable approach, economically beneficial, but its solution is possible only with the direct participation of relevant departmental organizations and state support.

Russia, which has the world's largest natural gas reserves, cannot afford not to take advantage of the situation to popularize CNG and possibly replace traditional fuels.

Sergey Kim October 2006

P.S. On my own behalf, I can add that my relative’s husband, who has been working as a taxi driver for more than 15 years, constantly converts his newly bought cars to methane, and after reworking, the cost of fuel for the car’s mileage is reduced by about 3 times compared to gasoline.

It is, so to speak, a direct experience.