The electrical circuit of the switch with illumination. Benefits of a backlit switch. Installation of a single switch

You can meet a switch with LED backlight today in almost every home. Using such a switch in the dark is much more convenient, but with the advent of fluorescent and LED lamps, problems began to arise with these “convenient” devices.

Some modern lamps, connected via a backlit wall switch, flicker even though the light is off. The blinking effect, which is unpleasant for the eye, occurs due to a closed electrical circuit formed by a resistor with an LED (or a resistor and a neon light bulb) and a power converter circuit for an LED or fluorescent lamp.

There are several ways to get rid of flashing in a 220V lamp, more on that already. In this article, we will consider the simplest and most reliable option in more detail. It consists in removing the backlight from the switch. So how to turn off the backlight in the switch? About everything in order.

Preparatory stage

If you have not encountered the replacement or installation of illuminated switches before, then you will have to prepare a little and think over your actions. In general, measures to remove a neon light bulb or LED can be divided into two stages:

- removing voltage from current-carrying wires;

- preparation of the necessary tool.

The first point is to de-energize the room in which the backlit switch is located. To do this, the handle of the circuit breaker must be turned to the "off" position. In some houses, fuses (plugs) are installed instead, which will have to be unscrewed. If the phase and neutral wires are connected to different machines, then both machines are turned off for complete safety (both plugs are removed).

The essence of the second stage is to avoid unnecessary fuss in search of the missing tool during the work. To remove the illuminated switch and turn off the backlight, you will need: an indicator screwdriver, a heavy-duty flat-head screwdriver, wire cutters and a knife.

Turn off the backlight

Initially, all actions for dismantling a neon lamp or LED are completely the same as replacing a conventional switch:

- de-energizing a room or apartment;

- removing the decorative on-off key from the latches, slightly prying it on both sides;

- unscrewing the fixing bolts and removing the device from the mounting box;

- with an indicator screwdriver, recheck the wire contacts for the absence of voltage;

- remembering the connection diagrams, the wires are disconnected.

Then you need to carefully consider the design of the illuminated switch and find the latches holding the two parts of the case. By opening the latches, the switch will be divided into two halves. In one of them, a resistor with a neon light bulb or LED is soldered or screwed.

It remains to carefully bite the conclusions of the radio components, remove them and assemble the switch without backlighting in reverse order.

In stores, you can often find switches that already have a built-in backlight. However, it is unlikely that anyone will want to change the installed switch just like that. But looking for a key in the dark by touch is also not always convenient.

The practicality of illuminated switches

The illuminated switch, the wiring diagram of which is almost the same as that of conventional switches, has become very popular. Anyone who is tired of looking for a switch in the dark of the night can make small changes to this device, even if he does not have special knowledge in electrics.

You can insert an LED into any switch using fairly simple circuits. Among themselves, the available schemes differ in their characteristics, and not only in the configuration. For example, a switch may not want to work due to the fact that an LED lamp is installed in the lamp. If the lamps are energy-saving, then they may glow in the dark or flicker, which is also not the correct result.

Switch connection diagrams

There are many acceptable schemes, each of which has its pros and cons. Understanding the existing backlight in the switch is not difficult.

For example, a backlit switch, the connection diagram of which is shown below.

When the switch is in the "Off" position, the current flows through the resistance (R1-any, in the range from 100 to 150 kOhm). After resistance, it passes through VD2 (an LED that glows at the same time). In order to protect the LED from voltage, we put the diode VD1. A resistor with a current of 3 mA shines especially well with this connection scheme. If it turns out that the LED glows rather weakly, then the resistance value should be reduced. Any LED and diode in this circuit will do. You can also calculate the required parameters of the resistor yourself. It is enough just to recall the classical law of current strength.

Consider another illuminated switch, the connection diagram of which is extremely simple, but with a slight drawback. The fact is that it consumes about 1 kilowatt per month.

We connect the ends directed downwards to the terminals. If there is no soldering iron in the house, or for some reason there is no desire to mess with it, then this circuit is perfect. It is made on twists. Although, for reasons of safety and durability of the device, it is still better to solder the joints, and insulate the resistor well.

Capacitor Switch LED Illumination Circuit

To increase the level of luminescence by an order of magnitude, you can use a capacitor. And the resistor current, on the contrary, is reduced to 90-100 ohms. You can use a backlit switch, the connection diagram of which differs from the previous one in that a capacitor is used instead of a resistor. And the resistor (R1) plays the role of a charging current limiter.

True, the backlight assembled according to this scheme is large in size, but it has an extremely low power consumption - about 0.05 watts per month.

Connecting a walk-through switch

If we consider the Legrand illuminated switch, the connection diagram of which is located above, it should be noted that it is safe to use this product, which is made of materials that significantly increase the service life. And there is no need to talk about the simplicity of connecting the switches of this company, everything is so thought out and easy to implement.

In the manufacture of switches, polycarbonate and galvanized steel are used. Screws, grips and caliper are all made of this metal. Keys, mechanisms, body and frame are made of polycarbonate. And this is a guarantee that for a long time with backlight, the connection scheme of which is extremely simple, will not crack or collapse from solar radiation.

Installing a two-gang switch

Two-key Legrand is distinguished by the presence of a pair of contacts that are independent of each other. When pressed on the keys, they switch the upper lines to the lower ones, and at the same time, the upper contacts are made with the absence of a final output. And the lower contacts are connected to the second, the same pass-through switch.

Knowing how the left and right groups of contacts are arranged, it is easy to understand how to connect a pass-through switch.

Connecting a pair of walk-through switches is extremely simple. The phase that comes out of the electrical panel of the apartment or house is fed to the contact of the second switch, while within the framework of the entire group, the contacts are interconnected by a jumper. And those contacts that are in the left group supply current to independent lighting devices. Here it is important to consider one rule. These two contacts should never be connected to each other. Then all four cross contacts must be linked together as a pair.

Legrand switches

"Legrand" is perhaps the most common brand among electrical appliances, and therefore most prefer to use their products, or close to them, but also well-known companies.

Among the products related to electrical fittings, it is necessary to single out sockets suitable for television and telephone networks - low-current, and all of them, except for excellent design, are of high quality, from which they have gained wide popularity not only in our country, but all over the world.

The principle of operation of the switches

Outwardly, a conventional switch practically does not differ from a pass-through switch, and it is impossible to visually distinguish them without revealing the design. The difference lies in the internal structure. A conventional switch opens or closes a circuit that carries an electric current, and a pass-through switch, connecting one line, disconnects the other. That is, in other words, when the pass-through switch is operating, no matter which pair of keys is pressed, the switch is ready for operation. Pressed the left on one switch - the light went out. They pressed the second one on it, or the key on the second switch - the light is on again. It is certainly very convenient.

In other words, for a conventional single-gang switch, both contacts are working, and for a walk-through switch, there are as many as three. Because the second contact, which acts as an output, is connected to the second switch, a pair. And when connecting two-button walk-through switches, the number of contacts increases to six.

If you carefully consider the connection diagram below, you can easily cope with the installation of any walk-through switches and install all the necessary devices in order for the circuit to function normally. The main thing is to observe safety precautions, do not work with the mains voltage turned on and make sure that a workable circuit is used.

backlit

Consider, perhaps, the most undemanding scheme with which you can connect such switches. Zero in the diagram is indicated in blue. He, once in the junction box, then goes to the lighting lamp. The orange wire is the phase. It passes from the same box to the input of the first of the switches. Then, at the outputs, the black wires must be connected to the input terminals of the second switch. And then, with just one wire, go to the lamp.

A double illuminated switch, the connection diagram of which is identical to those considered, is used as a device for controlling light sources that are separated from each other and can be located at a considerable distance. But they need to be managed from a specific location, and sometimes from two or three.

The comfort effect is especially noticeable when using a two-gang illuminated switch, the connection diagram of which is included in the kit, on stairs, in large rooms, when you don’t want to get up, for example, from the bed to turn off the light in the bedroom. If the switch is at the door, it is inconvenient before going to bed. Therefore, it is more logical to use a pass-through switch. One is installed as usual, at the door in the room, and the second near the bed, so that you can turn off the light without getting up.

Often use automatic adjustment of turning off and on the light. To do this, to detectors that respond to movement or sound. Or on lighting - when it gets dark, the light bulb turns on by itself and vice versa.

Thus, if a single-button illuminated switch is used, the connection diagram of which has already been considered, as well as walk-through switches with a different number of keys, any results in the implementation of design ideas and projects are easily achieved. And the ease of installation makes it possible to independently carry out work without resorting to the services of expensive specialists.

The glow-in-the-dark switch is very convenient to use, so the user, if possible, seeks to purchase just such a model.

Once these devices were equipped with a phosphorescent element, but this option has disadvantages: the glow gradually weakens and may go out altogether; in a room where daylight penetrates weakly, for example, in a corridor, there is no sense at all from a phosphorescent element, since it has nothing to “charge” with.

Therefore, today the switches are equipped with an electric backlight that works stably in any conditions. It will be discussed in our article, the topic of which is a backlit switch: wiring diagram.

The range of switches for household lighting circuits, including those with illumination, is currently extremely wide. On sale you can find products for every taste and, as they say, for all occasions.

All of them can be divided into several groups:

- Keyboards: the most common option. The key is usually plastic.

- Pushbutton: such a switch is very similar to the button with which the elevator is called in multi-storey buildings. Often it is made of stainless steel or aluminum - such a device fits very harmoniously into the high-tech style. The switch button can have not only a round, but also a rectangular or triangular shape, which gives the device an unusual look.

- Swivel: These are dimmer switches. They are able to smoothly regulate the voltage supplied to the lamp, which is why its luminosity changes just as smoothly. It is important to know that not all lamps can be connected through a dimmer. The fact that there is such an opportunity is indicated by the inscription on the box “dimmable” or “dimmable”.

- Touch: very stylish, modern version of the switch, which you just need to touch.

- Corded: such switches are most often equipped with wall sconces and they do not have lighting.

The wire switch is designed for installation in a square junction box measuring 86 by 86 mm

By the number of keys or buttons, the switches are divided into:

- Single-button: control only one circuit and are used, as a rule, to turn on only one light bulb.

- Two-key: connected to two circuits at once. This is the best option for a multi-lamp chandelier: through one key, power is supplied, for example, to two bulbs (dimmed light), and through the second - to all the others. An equally common use case is connecting the lighting of the toilet and bathroom, if they are separated by a partition (separate bathroom).

- With 3 and 4 keys: such devices are usually used to control lighting in several rooms, for example, in the same separate bathroom and hallway (3 keys) or, in addition, also on the stairs (4 keys).

Along with conventional switches, so-called ones are produced. They differ from ordinary ones in the presence of a movable contact, which is thrown between two fixed ones (the second name is a toggle switch).

This design allows you to implement a circuit in which one lamp is turned on by two switches.

It is used, for example, on a staircase or in a long corridor: when entering this room, the user turns on the light with the first switch, and when he is at the end of the corridor or at the top step of the stairs, he turns it off with the second.

Illuminated switch circuit

- We connect the phase wire to the moving contact of the first switch.

- From two fixed contacts on its other side we lay two wires to the fixed contacts of the second switch;

From the movable contact of the second switch we lay the wire to the lamp.

In any house equipped with electric lighting, there are switches. To make it easy to turn on the light at night, the switch is often equipped with a backlight, which is designed in such a way that it glows when the lighting in the room is turned off.

Before connecting a light switch, it is necessary to clarify the type of luminaire. This is because the backlight only works well with incandescent and halogen lamps. For luminaires with ballasts, the use of illuminated switches is not recommended.

A backlit switch differs from a conventional one only in that it contains a backlight indicator. This indicator can be a neon lamp or an LED with a limiting resistor. The backlit switch circuit is quite simple.

The indicator is connected in parallel with the switch terminals. When the light switch is turned off, the backlight indicator is connected to the neutral wire of the network through a small resistance and lights up. When the lighting is turned on, the indicator circuit is short-circuited and it goes out.

If the indicator is on, the lighting lamp does not light up, since the current passing through the indication circuit necessary for its normal operation is insufficient.

On a functional basis, there are backlit, push-button and other rare types.

Installation procedure - everything is simple and concise

The wiring diagram for the illuminated switch is based on the following sequence of actions:

The wiring diagram for the illuminated switch is based on the following sequence of actions:

- the lighting circuit is de-energized. For reliability, the absence of voltage is checked with a probe or multimeter;

- a box for the switch is installed and fixed in the opening in the wall. When replacing the old one, it is first dismantled;

- the key is removed from the switch and the power wires are connected. In parallel with the cables, the outputs of the backlight indicator are connected;

- the switch body is installed in the box and fixed with screws;

- the network and the switch, its backlight and the lighting network are turned on.

Do-it-yourself backlight for a switch

As you can see from the previous material, installing a backlit switch is not too difficult a task. In addition, it is quite possible to remake a conventional switch for these purposes yourself. Do-it-yourself LED backlighting is the most common option in modern conditions.

The backlight circuit consists of an LED, a limiting resistor, and a diode connected in parallel with the LED to protect it from reverse voltage breakdown. For a domestic type AL307 red LED, it must have a rating of 100 kOhm and a power of at least 1 watt. As a protective diode, you can use a KD521 type diode. The disadvantage of the scheme is the high power, which can be up to 1 kWh per month.

To save energy, you can use a circuit in which a capacitance of 1 uF is used to limit the current of the LED. In series with the capacitor, a resistor (100-500 Ohm) limiting the current of its charge is switched on.

The disadvantage of such a circuit is the use of a large capacitor, which can make it difficult to install the circuit in a circuit breaker.

The disadvantage of LED backlight circuits is that such circuits only work well for incandescent lamps. If the lamp has, then in the presence of such a backlight circuit, they will flash and glow when the switch is off. If there are LEDs in the lamp, the backlight circuit does not work on them at all. This is due to the high resistance of the LED lamp.

To control separate light sources from two, three or more places in rooms, corridors and landings, it is being introduced. This is not so difficult to do, especially with a detailed step-by-step installation guide at hand.

To control separate light sources from two, three or more places in rooms, corridors and landings, it is being introduced. This is not so difficult to do, especially with a detailed step-by-step installation guide at hand.

One of the ways to automatically turn on the light is connected to light bulbs that react to any movement within its visibility radius.

A simpler and more reliable neon lamp circuit includes, in addition to the lamp itself, a resistor connected in series with a resistance of 0.5-1.0 mΩ.

Installation of a switch with homemade lighting is simple.

A light bulb or LED is attached to the switch body with glue, and a small hole is drilled in the key for light.

The connection of such a backlight indicator is made in the same way as the industrial one.

conclusions:

- To increase comfort when switching on the lighting in the dark, a backlit switch is used.

- The backlight circuit can be made on an LED or a neon lamp. When choosing the type of illumination, it is necessary to take into account the type of luminaire.

- Installing a backlit switch is quite simple and not much different from connecting a simple switch.

- The simplicity of the backlight circuit allows you to upgrade a conventional switch and make a backlit switch out of it.

Features of connecting a backlit switch on video

Some people need instructions so that when the device burns out, they find out what they did wrong.

Making a switch backlight with an LED with your own hands is not difficult. An extremely simple circuit is assembled literally “on the knee” within a few minutes. But, if you don't want everything to end with fireworks and burnt wiring, read this article carefully.

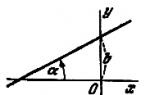

Scheme for turning on the LED in the switch in the apartment

Scheme and appearance of the switch

As you can see, the device consists of only two elements - a current-limiting resistor and a light source.

For many people who are not related to radio electronics, this scheme can be confusing. After all, we put the LED in a 220V AC switch, although the LED itself is designed for a voltage of 2-12V DC. And the main lamp, in theory, should also glow with such a connection.

How and why does it work?

Recall the school physics course:

- Voltage - potential difference at the two ends of the conductor. The higher the voltage, the faster the electrons run through the wires.

- Current strength - electron density in a conductor. When an area with high resistance is encountered in an electrical circuit in the path of electrons, some of them give up their energy to this area.

When the current strength (electron flux density) is significantly greater than this section is able to pass, the excess energy is converted into heat. If there were no resistor in front of the diode, the current passing through it would exceed its nominal parameters many times over, turning the diode crystal into a cloud. In this circuit, the resistor acts as a gate, cutting off most of the current. A current will also flow through the incandescent lamp itself, but its strength is so small that the spiral will not heat up.

Calculation of circuit parameters

We select a resistor for the LED. In this formula, the mains voltage is taken as 320V, since it is necessary to take into account not the nominal parameter, but the effective peak voltage.

We select a resistor

We select a resistor How to make a backlight for a switch

The main purpose of the LED illuminated switch circuit is to limit the amount of current flowing through the LED. For a diode, it doesn’t matter at what speed electrons pass through it, it will take its “portion” and convert it into a glow. If the density of the electron flux is higher than its throughput, the excess will be released in the form of heat, melting the crystal.

Installation LED in the 220V switch, diagram:

Options for connecting an LED

Options for connecting an LED Option 1

This connection method will work, but for a very short time, a few milliseconds, until the incandescent lamp coil flares up. With this connection, the circuit current will be calculated based on the needs of the lamp, exceeding the needs of the LED by hundreds of times. This is the wrong option.

Option 2

This is already a viable option. The current limiting resistor R1 will reduce the current to the required value. For a normal 20 mA LED, the resistor value should be:

(320V-3V) / 0.02A≈16 kOhm and power 0.25-0.5W.

For the sake of increasing the life of the backlight and reducing the heating of the resistor, it is better to increase the resistance parameters by 3-4 times. Such a scheme can be seen if you disassemble a cheap Chinese switch with an LED. There is no reverse current protection, which does not contribute to the long life of such a device.

Option 3

Turning on the diode with reverse polarity protects the LED from the reverse half wave. This is important if there are powerful devices on the line in the network: a washing machine, a boiler, an electric kettle. You can use any small diode with voltage up to 500-1000 volts.

Calculation examples

Since our task is only to illuminate the switch and achieve maximum viability, we take the LED current 30% of the nominal value - 6mA

Resistor current limiter

Usd = 3.5V, Isd = 20mA (0.02A) - We make the calculation for 6mA (0.006A);

R1 \u003d (330-3.5) / 0.006 \u003d 55000 Ohm (55 kOhm). In order to reduce heating, the resistor value can be increased by 2 times to 100 kOhm.

Resistor power P=Ur1 I=327 0.006=2W.

In parallel with the LED, it is better to turn on the 1000V diode in a mirror.

Capacitive current limiter

Instead of a resistor, you can use a high-voltage capacitor, R1 is necessary for self-discharge of the capacitor C1. The capacitive circuit does not heat up.

C1=Rc/(2 π £)=50kOhm/(2 3,14 50Hz)=150uF; C1=150uF*500V;

R1 \u003d 0.5-1 MΩ;

Diode as in the previous design.

If the switch is intended for an energy-saving lamp, it is better to replace the LED with a neon light bulb, the donor of which will be the starter of the fluorescent lamp. Classical circuits, due to the damping of a half-wave, can cause flickering of "energy savers". The connection principle remains the same, but due to the higher rated current, about 100mA, the resistor or capacitive resistance (on a neon light bulb) should be increased to 500-600 kOhm.

Application area

- switch circuit with LED backlight;

- power indicator in a portable extension cord;

- miniature night light;

- outlet lighting.

If desired, you can connect an LED strip, but only on a capacitive limiter after careful recalculation.

This is what the LED light looks like

This is what the LED light looks like  How to connect on a live example

How to connect on a live example Below is a diagram of how to connect a switch with an LED. Connection instructions

- Before starting the installation of the LED circuit in the switch, make sure that the switch is disconnected from the "phase". This can be done with a simple screwdriver tester.

- Check the insulation quality of all connecting contacts. Jumping bare wires, at best, will disable the backlight circuit, at worst, the wiring in the apartment.

- If necessary, a mounting hole can be made in the plastic part for the LED so that it evenly illuminates the switch button.

- We collect the resulting design and enjoy the result.

If we use the resistor option, it is worth experimenting with the resistance parameters. The diode can “start” from 2V or 3V, respectively, in the second, the resistor value can be reduced.

Do not forget that in such devices only the density of electrons is limited, the voltage remains the same and is still dangerous for living organisms.