Medial prosthesis. Types of dentures. So what are they

Adhesion is the bond between dissimilar surfaces brought into contact. The reasons for the emergence of an adhesive bond are the action of intermolecular forces or chemical interaction forces. Adhesion determines gluing solids - substrates- with adhesive adhesive, as well as the connection of a protective or decorative paintwork with the base. Adhesion also plays an important role in the dry friction process. In the case of the same nature of the contacting surfaces, one should speak of autohesia (autohesion), which underlies many processes for the processing of polymeric materials.With prolonged contact of identical surfaces and the establishment in the contact zone of a structure characteristic of any point in the volume of the body, the strength of the autohesive connection approaches cohesive strength of the material(cm. cohesion).

At the interface two liquids or a liquid and a solid body, adhesion can reach an extremely high value, since the contact between the surfaces in this case is complete. Adhesion of two solids due to uneven surfaces and contact only at certain points, as a rule, it is small. However, high adhesion can also be achieved in this case, if the surface layers of the contacting bodies are in a plastic or highly elastic state and are pressed against each other with sufficient force.

Adhesion of liquid to liquid or liquid to solid

From the point of view of thermodynamics, the cause of adhesion is a decrease in free energy per unit area of the adhesion joint in an isothermally reversible process. Work of reversible adhesive detachment W a determined from equations:

W a \u003d σ 1 + σ 2 - σ 12

where σ 1 and σ2 are the surface tension at the phase boundary, respectively 1 and 2 with the environment (air), and σ 12- surface tension at the phase boundary 1 and 2 between which adhesion takes place.

The value of adhesion of two immiscible liquids can be found from the equation given above by the easily determined values σ 1 , σ2 and σ 12. Vice versa, adhesion of a liquid to a solid surface, due to the impossibility of directly determining σ 1 rigid body, can only be calculated indirectly by the formula:

W a = σ 2 (1 + cos ϴ)

where σ2 and ϴ - measured values, respectively, of the surface tension of the liquid and the equilibrium wetting angle formed by the liquid with the surface of the solid. Due to wetting hysteresis, which does not allow accurate determination of the contact angle, only very approximate values are usually obtained from this equation. In addition, this equation cannot be used in the case of complete wetting, when cos ϴ = 1 .

Both equations, applicable in the case when at least one phase is liquid, are completely inapplicable for assessing the strength of the adhesive bond between two solids, since in the latter case, the destruction of the adhesive joint is accompanied by various kinds of irreversible phenomena due to various reasons: inelastic deformations adhesive and substrate, the formation of a double electric layer in the area of the adhesive joint, the rupture of macromolecules, the “pulling out” of the diffused ends of the macromolecules of one polymer from the layer of another, etc.

Adhesion of polymers to each other and to non-polymeric substrates

Almost all used in practice adhesives are polymer systems or form as a result of chemical transformations that occur after applying the adhesive to the surfaces to be glued. To non-polymer adhesives only inorganic substances such as cements and solders can be attributed.

Methods for determining adhesion and autohesion:

- The method of simultaneous separation of one part of the adhesive joint from the other over the entire contact area;

- The method of gradual delamination of the adhesive joint.

In the first method, the breaking load can be applied in a direction perpendicular to the plane of contact of the surfaces (peel test) or parallel to it (shear test). The ratio of the force overcome with simultaneous separation over the entire contact area to the area is called adhesive pressure , adhesion pressure or adhesion strength (n / m 2, dyn / cm 2, kgf / cm 2). Pull-off method gives the most direct and accurate characteristic of the strength of the adhesive joint, however, its use is associated with some experimental difficulties, in particular, the need for a strictly centered application of the load to the test sample and ensuring a uniform distribution of stresses over the adhesive joint.

The ratio of the forces overcome during gradual delamination of the sample to the width of the sample is called peel resistance or peel resistance (n/m, dyn/cm, gf/cm); often the adhesion determined during delamination is characterized by the work that must be spent on separating the adhesive from the substrate (j / m 2, erg / cm 2) (1 j / m 2 \u003d 1 n / m, 1 erg / cm 2 \u003d 1 dyn / cm).

Determination of adhesion by delamination it is more appropriate in the case of measuring the strength of the bond between a thin flexible film and a solid substrate, when, under operating conditions, the peeling of the film usually proceeds from the edges by slowly deepening the crack. With adhesion of two rigid solid bodies, the tear-off method is more indicative, since in this case, when sufficient force is applied, almost simultaneous tear-off can occur over the entire contact area.

Adhesion meter

Adhesion and autohesion during peel, shear and delamination tests can be determined on conventional dynamometers or on special ones. To ensure complete contact between the adhesive and the substrate, the adhesive is used in the form of a melt, a solution in a volatile solvent, or which polymerizes when an adhesive compound is formed. However, during curing, drying, and polymerization, the adhesive typically shrinks, resulting in tangential stresses at the interfacial surface that weaken the adhesive bond.

These stresses can be largely eliminated:

- the introduction of fillers, plasticizers into the glue,

- in some cases, heat treatment of the adhesive joint.

The strength of the adhesive bond determined during the test can be significantly affected by:

- dimensions and design of the test sample (as a result of the action of the so-called. edge effect),

- thickness of the adhesive layer,

- past history of adhesive bonding

- and other factors.

About values adhesion strength or autohesion, we can say, of course, only in the case when the destruction occurs along the interfacial boundary (adhesion) or in the plane of the initial contact (autohesion). When the sample is destroyed by the adhesive, the obtained values characterize cohesive strength of the polymer. Some scientists believe, however, that only cohesive failure of an adhesive joint is possible. The observed adhesive nature of the destruction, in their opinion, is only apparent, since visual observation or even observation with an optical microscope does not make it possible to detect the remaining thinnest layer of adhesive on the surface of the substrate. However, it has recently been shown both theoretically and experimentally that the destruction of an adhesive joint can be of the most diverse nature - adhesive, cohesive, mixed, and micromosaic.

For methods for determining the strength of an adhesive bond, see testing of paints and varnishes andcovered.

Theories of adhesion

Mechanical adhesion

According to this concept, adhesion occurs as a result of flow of glue into the pores and cracks of the surface of the substrate and subsequent curing of the glue; if the pores have an irregular shape, and especially if they expand from the surface into the depths of the substrate, they form as if "rivets" binding adhesive and substrate. Naturally, the adhesive must be hard enough so that the "rivets" do not slip out of the pores and crevices into which it flows. Mechanical adhesion is also possiblein the case of a substrate penetrated by a system of through pores. Such a structure is typical, for example, for tissues.Finally, the third case of mechanical adhesion comes down to the fact that the villi located on the surface of the fabric, after applying and curing the adhesive, are firmly embedded in the adhesive.

Although mechanical adhesion in some cases, it certainly plays a significant role, but, according to most researchers, it cannot explain all cases of gluing, since perfectly smooth surfaces that do not have pores and cracks can also stick together well.

Molecular theory of adhesion

Debroyne, adhesion is due to the action van der Waals forces(dispersion forces, interaction forces between constant or between constant and induced dipoles), interaction - dipole or education. Debroyn substantiated his theory of adhesion with the following facts:

- The same adhesive can bond different materials;

- Chemical interaction between the adhesive and the substrate due to their usually inert nature is unlikely.

Debroyn has a well-known rule: strong bonds are formed between the adhesive and the substrate, close in polarity. In application to polymers molecular (or adsorption) theory developed in the works McLaren. The adhesion of polymers according to McLaren can be divided into two stages:

- migration of large molecules from a solution or melt of an adhesive to the surface of a substrate as a result of Brownian motion; while the polar groups or groups capable of forming a hydrogen bond approach the corresponding group of the substrate;

- establishment of adsorption equilibrium.

When the distance between the adhesive and substrate molecules is less 0.5 nm van der Waals forces begin to act.

According to McLaren, in the amorphous state, polymers have greater adhesion than in the crystalline state. In order for the active sites of the adhesive molecule to continue to contact the active sites of the substrate when the adhesive solution dries, which is always accompanied by shrinkage, the adhesive must have a sufficiently low . On the other hand, he must show certain tensile or shear strength. That's why adhesive viscosity should not be too small, but its degree of polymerization must lie within 50-300 . At lower degrees of polymerization, adhesion is low due to chain slip, and at higher degrees, the adhesive is too hard and rigid, and the adsorption of its molecules by the substrate is difficult. The adhesive must also have certain dielectric properties (polarity) corresponding to the same properties of the substrate. McLaren considers the best measure of polarity to be μ 2 /ε, where μ is the dipole moment of the substance molecule, and ε - the dielectric constant.

Thus, according to McLaren, adhesion is a purely surface process due to adsorption certain sections of the adhesive molecules on the surface of the substrate. McLaren proves the correctness of his ideas by the influence of a number of factors on adhesion (temperature, polarity, nature, size and shape of adhesive molecules, etc.). McLaren derived dependencies that quantitatively describe adhesion. For example, for polymers containing carboxyl groups, it was found that the strength of the adhesive bond (BUT ) depends on the concentration of these groups:

A=k[COOH] n

where [UNSD]- concentration of carboxyl groups in the polymer; k and n - constants.

For a long time it remained unclear whether intermolecular forces could provide the adhesion observed experimentally.

- First, it was shown that when a polymer adhesive is peeled off from the surface of a substrate, work is expended several orders of magnitude higher than that required to overcome the forces of intermolecular interaction.

- Secondly, a number of researchers have found that the work of adhesion depends on the rate of peeling of the polymer adhesive, while if the adsorption theory is correct, this work, it would seem, should not depend on the rate of expansion of the surfaces in contact.

However, recent theoretical calculations have shown that intermolecular forces can provide the strength of adhesive interaction observed experimentally even in the case of nonpolar adhesive and substrate. Discrepancy between the work expended on peeling and the work expended against the action of adhesive forces, is explained by the fact that the first one also includes the work of deformation of the adhesive joint elements. Finally, dependence of the work of adhesion on the rate of delamination can be satisfactorily interpreted if we extend to this case the ideas that explain the dependence of the cohesive strength of the material on the rate of deformation by the influence of thermal fluctuations on the breakdown of bonds and relaxation phenomena.

Electrical theory of adhesion

The authors of this theory are Deryagin and Krotov. Later, similar views were developed Skinner with employees (USA). Deryagin and Krotova base their theory on the phenomena of contact electrification, which occurs when two dielectrics or a metal and a dielectric come into close contact. The main tenets of this theory are that the system adhesive substrate is identified with the capacitor, and the double electric layer, which occurs when two dissimilar surfaces come into contact, with the capacitor plates. When the adhesive peels off from the substrate, or, what is the same, when the capacitor plates are moved apart, a difference in electric potentials arises, which increases with an increase in the gap between the moved apart surfaces to a certain limit, when a discharge occurs. The work of adhesion in this case can be equated to the energy of the capacitor and determined by the equation (in the CGS system):

Wa = 2πσ 2 h/ε a

where σ - surface density of electric charges; h - discharge gap (gap thickness between plates); ε a is the absolute permittivity of the medium.

With slow separation, the charges have time to largely drain from the capacitor plates. As a result, the neutralization of the initial charges has time to end with a small dilution of the surfaces, and little work is expended on the destruction of the adhesive joint. With the rapid expansion of the capacitor plates, the charges do not have time to drain and their high initial density is maintained until the onset of a gas discharge. This causes large values of the work of adhesion, since the action of the forces of attraction of opposite electric charges is overcome at relatively large distances. Different nature of charge removal from the surfaces formed during delamination adhesive-air and substrate-air the authors of the electrical theory and explain the characteristic dependence of the work of adhesion on the rate of delamination.

The possibility of electrical phenomena during the delamination of adhesive joints is indicated by a number of facts:

- electrification of the formed surfaces;

- the appearance in some cases of delamination of an avalanche electric discharge, accompanied by glow and crackling;

- change in the work of adhesion when replacing the medium in which delamination is performed;

- a decrease in the work of delamination with an increase in the pressure of the surrounding gas and during its ionization, which contributes to the removal of charge from the surface.

The most direct confirmation was the discovery of the phenomenon of electron emission observed when polymer films were detached from various surfaces. The values of the adhesion work calculated from the measurement of the velocity of emitted electrons were in satisfactory agreement with the experimental results. It should, however, be noted that electrical phenomena during the destruction of adhesive joints appear only with completely dry samples and at high delamination rates (not less than tens of cm/sec).

The electrical theory of adhesion cannot be applied to a number of cases of adhesion of polymers to each other.

- It cannot satisfactorily explain the formation of an adhesive bond between polymers that are similar in nature. Indeed, a double electric layer can appear only at the contact boundarytwo different polymers. Therefore, the strength of the adhesive bond should decrease as the nature of the polymers brought into contact approaches. In fact, this is not observed.

- Non-polar polymers, based only on the ideas of electrical theory, cannot give a strong bond, since they are not capable of being donors and, therefore, cannot form an electrical double layer. Meanwhile, practical results refute these arguments.

- Filling rubber with carbon black, contributing to the high electrical conductivity of carbon black-filled mixtures, should make adhesion between them impossible. However, the adhesion of these mixtures not only to each other, but also to metals is quite high.

- The presence of a small amount of sulfur introduced into rubbers for vulcanization should not change adhesion, since the effect of such an addition on the contact potential is negligible. In fact, after vulcanization, the adhesion ability disappears.

Diffusion theory of adhesion

According to this theory, proposed Voyutsky To explain the adhesion of polymers to each other, adhesion, like autohesion, is determined by intermolecular forces, and the diffusion of chain molecules or their segments provides the maximum possible interpenetration of macromolecules for each system, which contributes to an increase in molecular contact. A distinctive feature of this theory, which is especially suitable in the case of polymer-to-polymer adhesion, is that it proceeds from the main features of macromolecules - chain structure and flexibility. It should be noted that, as a rule, only adhesive molecules have the ability to diffuse. However, if the adhesive is applied as a solution, and the polymeric substrate is able to swell or dissolve in this solution, there may be a noticeable diffusion of the substrate molecules into the adhesive. Both of these processes lead to the disappearance of the boundary between the phases and to the formation of a soldering, which is a gradual transition from one polymer to another. In this way, adhesion of polymers is considered as a three-dimensional phenomenon.

It is also quite obvious that diffusion of one polymer into another is the phenomenon of dissolution.

Mutual solubility of polymers, which is mainly determined by the ratio of their polarities, is very important for adhesion, which is quite consistent with the well-known Debroyn's rule. However, noticeable adhesion can also be observed between incompatible polymers that differ greatly in polarity, as a result of the so-called. local diffusion, or local dissolution.

Local dissolution of a non-polar polymer in a polar can be explained by the heterogeneity of the microstructure of a polar polymer, which arises as a result of the fact that a polymer consisting of chains with polar and nonpolar regions of sufficient length always undergoes microseparation, similar to that occurring in mixtures of polymers that differ greatly in polarity. Such local dissolution is likely in the case when hydrocarbon chains diffuse, since in polar polymers the volume of non-polar regions is usually larger than the volume of polar groups. This explains the fact that non-polar elastomers usually exhibit noticeable adhesion to polar high molecular weight substrates, while polar elastomers almost do not adhere to non-polar substrates. In the case of nonpolar polymers, local diffusion may be due to the presence in one or both polymers of supramolecular structures that exclude diffusion in certain areas of the interfacial surface. The significance of the considered process of local dissolution, or local diffusion, for adhesion is all the more likely because, according to calculations, penetration of adhesive molecules into the substrate by only a few tenths of nm (several Å ) to increase the adhesive strength many times over. Recently Dogadkin and Kuleznev the concept is developing, according to which on the interfacial surface of the contact of two little or almost completely incompatible polymers can proceed diffusion of the end segments of their molecules (segmental diffusion). The rationale for this point of view is that the compatibility of polymers increases as their molar mass decreases. In addition, the formation of a strong adhesive bond can be determined not only by the intertwining of molecular chains in the contact zone due to bulk diffusion, but also by the diffusion of molecules of one polymer over the surface of another. Even when adhesion is due to purely adsorption interactions, adhesive strength almost never reaches its limit value, since the active groups of the adhesive molecules never fit exactly on the active sites of the substrate. However, it can be assumed that with an increase in time or with an increase in the contact temperature, the stacking of molecules will become more perfect as a result of surface diffusion of individual segments of macromolecules. As a result, the strength of the adhesive bond will increase. According to the diffusion theory, the strength of an adhesive bond is due to the usual molecular forces that act between intertwined macromolecules.

Sometimes the adhesion of polymers cannot be explained in terms of their interdiffusion and one has to resort to adsorption or electrical concepts. This applies, for example, to the adhesion of completely incompatible polymers or to the adhesion of an elastomer to a polymer substrate, which is a cross-linked polymer with a very dense spatial network. However, in these cases, adhesion is usually low. Since the diffusion theory provides for the formation of a strong transition layer between the polymers that form the adhesive seam, it easily explains the discrepancy between the work of delamination and the work required to overcome the forces acting between the adhesive and the substrate. In addition, the diffusion theory makes it possible to explain the dependence of the adhesion work on the delamination rate on the basis of the same principles on which the explanation of the change in the strength of a polymer sample with a change in the rate of its stretching is based.

In addition to general considerations pointing to the correctness of the diffusion theory of adhesion, there are experimental data that speak in its favor. These include:

- positive impact on adhesionandautohesion of polymers increasing the duration and temperature of contact between the adhesive and the substrate;

- an increase in adhesion with a decrease in , polarity and polymers;

- a sharp increase in adhesion with a decrease in the content of short side branches in the adhesive molecule, etc.

The influence of the factors causing an increase in the adhesion or autohesion of polymers fully correlates with their influence on the diffusion capacity of macromolecules.

Results of a quantitative test of the diffusion theory polymer adhesion by comparing the experimentally found and theoretically calculated dependences of the work of delamination of an autohesive joint on the contact time and mol. the masses of polymers turned out to be in good agreement with the concept of the diffusion mechanism of the formation of an autohesive bond. Diffusion of macromolecules upon contact of two polymers has also been proven experimentally by direct methods, in particular, using electron microscopy. Observation of the contact boundary between two compatible polymers in a viscous-flowing or highly elastic state showed that it is smeared over time, and the more so, the higher the temperature. Values diffusion rate polymers, calculated from the width of the blurred zone, turned out to be quite high and make it possible to explain the formation of an adhesive bond between the polymers.

All of the above refers to the simplest case, when the presence of supramolecular structures in the polymer practically does not manifest itself in the processes and properties under consideration. In the case of polymers, the behavior of which is greatly influenced by the existence of supramolecular structures, diffusion can be complicated by a number of specific phenomena, for example, partial or complete diffusion of molecules from a supramolecular formation located in one layer to a supramolecular formation in another layer.

Adhesion due to chemical interaction

In many cases, adhesion can be explained not by physical, but by chemical interactions between polymers. At the same time, the exact boundaries between adhesion due to physical forces and adhesion resulting from chemical interaction cannot be established. There is reason to believe that chemical bonds can arise between the molecules of almost all polymers containing active functional groups, between such molecules and surfaces of metal, glass, etc., especially if the latter are covered with an oxide film or a layer of erosion products. It should also be taken into account that rubber molecules contain double bonds, which under certain conditions determine their chemical activity.

The considered theories, based on the predominant role of any one specific process or phenomenon in the formation or destruction of an adhesive bond, are applicable to various cases of adhesion.or even to various aspects of this phenomenon. So, molecular theory of adhesion considers only the final result of the formation of an adhesive bond and the nature of the forces acting between the adhesive and the substrate. diffusion theory, on the contrary, explains only the kinetics of the formation of an adhesive bond and is valid only for the adhesion of more or less mutually soluble polymers. AT electrical theory the main attention is paid to the consideration of the processes of destruction of adhesive joints. Thus, a unified theory explaining adhesion phenomena, no, and probably cannot be. In various cases, adhesion is due to different mechanisms, depending both on the nature of the substrate and adhesive, and on the conditions for the formation of an adhesive bond; many cases of adhesion can be explained by the action of two or more factors.

ADHESION

ADHESION

(from lat. adhaesio -), the emergence of a connection between the surface layers of two heterogeneous (solid or liquid) bodies (phases) brought into contact. It is the result of intermolecular interaction, ionic or metallic. connections. A special case of A. - - the effect of identical bodies in contact. Limiting case A. - chem. impact on the interface (chemisorption) with the formation of a layer of chemical. connections. A. is measured by force or work of separation per unit. surface contact area (adhesion seam) and becomes extremely large with full contact over the entire area of contact of the bodies (for example, when applying a liquid (varnish, glue) to a solid body under conditions of complete wetting; the formation of one body as a new phase of another; the formation of electroplating etc.).

In the process of A., the free body decreases. The decrease in this energy per 1 cm2 of the adhesive joint, called. free energy A. fA, which is equal to the work of adhesive separation WA (with the opposite sign) under conditions of a reversible isothermal. process and is expressed in terms of tension at the interfaces of the first body - ext. environment (in which the bodies are located) s10, the second body is the environment s20, the first body is the second body s12:

FA=WA=s12-s10-s20.

With complete wetting q=0 and W=2s10.

A set of methods for measuring the force of separation or chipping with A. called. adgez i o m e t r i e y. A. may be accompanied by mutual diffusion of the in-in, which leads to blurring of the adhesive seam.

Physical Encyclopedic Dictionary. - M.: Soviet Encyclopedia. . 1983 .

ADHESION

(from Latin adhaesio - sticking, cohesion, attraction) - connection between dissimilar condensed bodies upon their contact. A special case of A. is autohesion, which manifests itself when homogeneous bodies come into contact. With A. and autohesion, the phase boundary between the bodies is preserved, in contrast to cohesion, determining the connection within the body within one phase. Naib. What matters is A. to a solid surface (substrate). Depending on the properties of the adhesive (adhering body), adhesives are distinguished between liquids and solids (particles, films, and structured elastoviscoplastic masses, such as melts and bitumen). Autohesion is characteristic of solid films in multilayer coatings and particles; it determines disperse systems and compositions. materials (powders, soil, concrete, etc.).

A. depends on the nature of the contacting bodies, St. in their surfaces and the area of contact. A. is determined by the forces of intermolecular attraction and is enhanced if one or both bodies are electrically charged, if a donor-acceptor bond is formed upon contact of the bodies, and also due to capillary condensation of vapors (for example, water) on surfaces, as a result of the occurrence of chemical. bonds between the adhesive and the substrate. In the process of diffusion, the molecules of the contacting bodies can interpenetrate, the interface between phases can be washed out, and the atom can pass into cohesion. The value of A. may change with adsorption at the interface, as well as due to the mobility of polymer chains Between solid bodies in a liquid medium, a thin layer of liquid is formed and arises, preventing A. The consequence of A. liquid to the surface of a solid body is wetting.

Possibility And. at isothermal. reversible process is determined by the loss of free surface energy, which is equal to the equilibrium work of adhesion:

![]()

where are the surface tensions of the substrate 1 and adhesive 2 at the border with the environment 3 (for example, air) to A. and at A. With an increase in the surface tension of the substrate, A. grows (for example, it is large for metals and small for polymers). The given equation is the starting point for calculating the equilibrium work of an A. liquid. A. solids is measured by the value of ext. exposure to detachment of the adhesive, A. and autohesion of particles - by average force (calculated as a mathematical expectation), and powder - beats. by force. The forces of A. and autohesion of particles increase friction during the movement of powders.

When tearing off films and structured. masses, the adhesive strength is measured, edges, except for A., include the force on deformation and the flow of the sample, the discharge of a double electric. layer and other phenomena. Adhesion strength depends on the dimensions (thickness, width) of the sample, the direction and speed of application of the external. efforts. When adhesion is weak compared to cohesion, adhesive separation occurs, and when cohesion is relatively weak, a cohesive tear of the adhesive occurs. A. polymer, paint and other films is determined by wetting, the condition for the formation of the contact area with a liquid adhesive and, when it hardens, the formation of an internal. stresses and relaxation. processes, the influence of external. conditions (pressure, temperature, electric fields, etc.), and the strength of adhesive joints is also the cohesion of the hardened adhesive layer.

Change A. due to the occurrence of a double electric. layer in the contact zone and the formation of a donor-acceptor bond for metals and crystals is determined by the states of the external. electrons of atoms of the surface layer and crystal defects. lattices, semiconductors - surface states and the presence of impurity atoms, and dielectrics - the dipole moment of functional groups of molecules at the phase boundary. The area of contact (and the value of A.) of solid bodies depends on their elasticity and plasticity. A. can be strengthened by activation, i.e., changes in morphology and energy. mechanical surfaces cleaning, cleaning with solutions, evacuation, exposure to el.-mag. radiation, ion bombardment, as well as the introduction of decomp. functional groups. Means. A. metallic. films is achieved by electrodeposition, metallic. and non-metal. film - thermal. evaporation and vacuum deposition, refractory films - using a plasma jet.

The set of methods for determining A. called. adhesiometry, and the devices that implement them - adhesiometers. A. can be measured using direct (force when adhesive contact is broken), non-destructive (by changing the parameters of ultrasonic and electromagnetic waves due to absorption, reflection or refraction) and indirect (characterizing A. under comparable conditions only relatively, for example. peeling films after notching, tilting the surface for powders, etc.) methods.

Lit .: Zimon A. D., Adhesion of dust and powders, 2nd ed., M., 1976; his own, Adhesion of films and coatings, M., 1977; his, What is adhesion, M., 1983; Deryagin B. V., Krotova N. A., Smilga V. P., Adhesion of solids, M., 1973; 3imon A. D., Andrianov E. I., Autogesia of bulk materials, M., 1978; Basin V. E., Adhesion strength, M., 1981; Coagulation contacts in disperse systems, M., 1982; Vakula V. L., Pritykin L. M., Physical chemistry of polymer adhesion, M., 1984. A. D. Zimon.

Physical encyclopedia. In 5 volumes. - M.: Soviet Encyclopedia. Editor-in-Chief A. M. Prokhorov. 1988 .

Synonyms:

See what "ADGESION" is in other dictionaries:

- (from Latin adhaesio sticking) in physics, the adhesion of surfaces of dissimilar solid and / or liquid bodies. Adhesion is due to intermolecular interactions (van der Waals, polar, sometimes the formation of chemical bonds or ... ... Wikipedia

adhesion- adhesion strength The totality of forces that bind the coating to the surface to be painted. [GOST R 52804 2007] adhesion A surface phenomenon resulting in adhesion between dissimilar materials brought into contact under the influence of physical ... ... Technical Translator's Handbook

Adhesion- - adhesion of surfaces of dissimilar bodies. It is achieved when applying electroplated and paint coatings, gluing, welding, etc., as well as during the formation of surface films (for example, oxide, sulfide). When the molecules of the same... Encyclopedia of terms, definitions and explanations of building materials

- (lat. adhaesio, from adhaerere to stick, to be connected). Sticking, grip. Dictionary of foreign words included in the Russian language. Chudinov A.N., 1910. ADHESION lat. adhaesio, from adhaerere, to stick. Sticking. Explanation of 25,000 foreign ... Dictionary of foreign words of the Russian language

Sticking, gluing, sticking, gluing, adhesion Dictionary of Russian synonyms. adhesion noun, number of synonyms: 5 gluing (12) … Synonym dictionary

adhesion- and, well. adhésion f., German Adhäsion lat. adhaesio adhesion. 1372. Lexis. The adhesion of the surfaces of two dissimilar solid or liquid bodies. SIS 1985. The phenomenon of gluing has been known for a long time, but they began to think about its nature relatively recently ... ... Historical Dictionary of Gallicisms of the Russian Language

- (from lat. adhaesio sticking) adhesion of surfaces of dissimilar bodies. Thanks to adhesion, the application of galvanic and paint coatings, gluing, welding, etc., as well as the formation of surface films (for example, oxide) are possible ... Big Encyclopedic Dictionary

ADHESION, the attraction of the molecules of one substance to the molecules of another. In rubbers, adhesives and pastes, the property of adhesion to hold various substances together. see also COHESION ... Scientific and technical encyclopedic dictionary

Polar, sometimes - mutual diffusion) in the surface layer and is characterized by the specific work necessary to separate the surfaces. In some cases, adhesion may be stronger than cohesion, that is, adhesion within a homogeneous material, in such cases, when a tearing force is applied, a cohesive gap occurs, that is, a gap in the volume of the less durable of the contacting materials.

Adhesion significantly affects the nature of friction of the contacting surfaces: for example, when interacting surfaces with low adhesion, friction is minimal. An example is polytetrafluoroethylene (Teflon), which, due to its low adhesion value, in combination with most materials, has a low coefficient of friction. Some substances with a layered crystal lattice (graphite, molybdenum disulfide), characterized by both low adhesion and cohesion values, are used as solid lubricants.

The most well-known adhesion effects are capillarity, wettability/nonwetting, surface tension, liquid meniscus in a narrow capillary, rest friction of two absolutely smooth surfaces. The criterion for adhesion in some cases may be the time of detachment of a layer of material of a certain size from another material in a laminar fluid flow.

Adhesion takes place in the processes of gluing, soldering, welding, coating. The adhesion of the matrix and filler of composites (composite materials) is also one of the most important factors affecting their strength.

Encyclopedic YouTube

-

1 / 5

Adhesion is an extremely complex phenomenon, which is the reason for the existence of many theories that interpret this phenomenon from different positions. The following theories of adhesion are currently known:

- adsorption theory, according to which the phenomenon is carried out as a result of the adsorption of the adhesive on the pores and cracks of the surface of the substrate.

- mechanical theory considers adhesion as a result of the manifestation of the forces of intermolecular interaction between the contacting molecules of the adhesive and the substrate.

- electrical theory identifies the "adhesive-substrate" system with a capacitor, and the double electrical layer, which occurs when two dissimilar surfaces come into contact, with the capacitor lining.

- Electronic theory considers adhesion as a result of the molecular interaction of surfaces that are different in nature.

- diffusion theory reduces the phenomenon to mutual or one-sided diffusion of adhesive and substrate molecules.

- chemical theory explains adhesion not by physical, but by chemical interaction.

Physical Description

Adhesion is a reversible thermodynamic work of forces aimed at separating two dissimilar (heterogeneous) phases brought into contact. Described by the Dupre equation:

W a = σ 13 + σ 23 − σ 12 (\displaystyle (Wa=\sigma _(13)+\sigma _(23)-\sigma _(12)))

W a = − Δ G o (\displaystyle (Wa=-\Delta G^(o)))

A negative value of ΔG° indicates a decrease in the work of adhesion as a result of the formation of interfacial tension.

Changes in the Gibbs energy of the system during the adhesion process:

Δ G 1 o = σ 13 + σ 23 (\displaystyle (\Delta G_(1)^(o)=\sigma _(13)+\sigma _(23)))

Δ G 2 o = σ 12 (\displaystyle (\Delta G_(2)^(o)=\sigma _(12)))

Δ G o = Δ G 2 o − Δ G 1 o (\displaystyle (\Delta G^(o)=\Delta G_(2)^(o)-\Delta G_(1)^(o)))

σ 12 − σ 13 − σ 23 = Δ G o (\displaystyle (\sigma _(12)-\sigma _(13)-\sigma _(23)=\Delta G^(o))).

At the interface between two phases (liquid-gas), cosθ is the contact angle of wetting, Wa is the reversible work of adhesion.

The concept of cohesion and adhesion. Wetting and spreading. The work of adhesion and cohesion. Dupre's equation. Wetting angle. Young's law. Hydrophobic and hydrophilic surfaces

In heterogeneous systems, intermolecular interactions are distinguished within phases and between them.

cohesion - attraction of atoms and molecules within a separate phase. It determines the existence of matter in a condensed state and can be due to intermolecular and interatomic forces. concept adhesion, wetting and spreading refer to interfacial interactions.

Adhesion provides a connection between two bodies of a certain strength due to physical and chemical intermolecular forces. Consider the characteristics of the cohesive process. Work cohesion is determined by the energy consumption for the reversible process of body rupture over a section equal to a unit area: W k =2 , where W k- work of cohesion; - surface tension

Since a surface is formed in two parallel areas during rupture, a coefficient of 2 appears in the equation. Cohesion reflects the intermolecular interaction inside a homogeneous phase, it can be characterized by such parameters as the energy of the crystal lattice, internal pressure, volatility, boiling point, adhesion is the result of the system's tendency to decrease in surface energy. The work of adhesion is characterized by the work of reversible breaking of the adhesive bond, per unit area. It is measured in the same units as surface tension. The total work of adhesion pertaining to the entire contact area of the bodies: W s = W a S

In this way, adhesion - work to break the adsorption forces with the formation of a new surface in 1m 2 .

To obtain the relationship between the work of adhesion and the surface tension of the interacting components, imagine two condensed phases 2 and 3, having a surface at the border with air 1 equal to a unit area (Fig. 2.4.1.1).

We assume that the phases are mutually insoluble. When combining these surfaces, i.e. when applying one substance to another, the phenomenon of adhesion occurs, because the system has become two-phase, then interfacial tension 23 appears. As a result, the initial Gibbs energy of the system is reduced by an amount equal to the work of adhesion:

G

+

W a =0,

W a =

-

G

+

W a =0,

W a =

-

G.

G.

Change in the Gibbs energy of the system during the adhesion process:

G early = 31 + 21 ;

G con \u003d 23;

;

; .

. - Dupre's equation.

- Dupre's equation.It reflects the law of conservation of energy during adhesion. It follows from this that the work of adhesion is the greater, the greater the surface tension of the initial components and the lower the final interfacial tension.

The interfacial tension will become 0 when the interfacial surface disappears, which occurs when the phases are completely dissolved

Given that W k =2 , and multiplying the right side by the fraction

, we get:

, we get:

where W k 2, W k 3 - work of cohesion of phases 2 and 3.

Thus, the dissolution condition is that the work of adhesion between interacting bodies must be equal to or greater than the average value of the sum of cohesive works. It is necessary to distinguish adhesive strength from the work of cohesion. W P .

W P – work expended on the destruction of the adhesive joint. This value differs in that it includes as the work of breaking intermolecular bonds W a, and the work spent on the deformation of the components of the adhesive joint W def :

W P = W a + W def .

The stronger the adhesive joint, the greater the deformation of the system components in the process of its destruction. The work of deformation can exceed the reversible work of adhesion by several times.

Wetting - surface phenomenon consisting in the interaction of a liquid with a solid or other liquid body in the presence of simultaneous contact of three immiscible phases, one of which is usually a gas.

The degree of wettability is characterized by the dimensionless value of the cosine of the wetting angle or simply the contact angle. In the presence of a liquid drop on the surface of a liquid or solid phase, two processes are observed, provided that the phases are mutually insoluble.

The liquid remains on the surface of the other phase in the form of a drop.

The drop spreads over the surface.

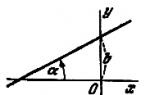

On fig. 2.4.1.2 shows a drop on the surface of a solid under equilibrium conditions.

The surface energy of a solid body, tending to decrease, stretches the drop over the surface and is equal to 31 . The interfacial energy at the solid-liquid interface tends to compress the drop, i.e. surface energy is reduced by decreasing surface area. Spreading is prevented by cohesive forces acting inside the drop. The action of cohesive forces is directed from the boundary between the liquid, solid and gaseous phases tangentially to the spherical surface of the drop and is equal to 21 . The angle (theta) formed by the tangent to the interfacial surfaces that bound the wetting liquid has a vertex at the interface of three phases and is called contact angle . At equilibrium, the following relation is established

-

young's law.

-

young's law.This implies a quantitative characteristic of wetting as the cosine of the contact angle of wetting

. The smaller the contact angle of wetting and, accordingly, the larger cos , the better wetting.

. The smaller the contact angle of wetting and, accordingly, the larger cos , the better wetting.If cos > 0, then the surface is well wetted by this liquid, if cos < 0, то жидкость плохо смачивает это тело (кварц – вода – воздух: угол = 0; «тефлон – вода – воздух»: угол = 108 0). С точки зрения смачиваемости различают гидрофильные и гидрофобные поверхности.

If 0< угол <90, то поверхность гидрофильная, если краевой угол смачиваемости >90, then the surface is hydrophobic. A convenient formula for calculating the magnitude of the work of adhesion is obtained by combining the Dupre formula and Young's law:

;

; -

Dupre-Young equation.

-

Dupre-Young equation.This equation shows the difference between the phenomena of adhesion and wettability. Dividing both sides by 2, we get

.

.

Since wetting is quantitatively characterized by cos , then, in accordance with the equation, it is determined by the ratio of the work of adhesion to the work of cohesion for the wetting liquid. The difference between adhesion and wetting is that wetting takes place when three phases are in contact. The following conclusions can be drawn from the last equation:

1. When = 0 cos = 1, W a = W k .

2. When = 90 0 cos = 0, W a = W k /2 .

3. When =180 0 cos = -1, W a =0 .

The last relation is not realized.