Chemical properties of aluminum table. The structure of the aluminum atom

Each chemical element can be considered from the point of view of three sciences: physics, chemistry and biology. And in this article we will try to characterize aluminum as accurately as possible. This is a chemical element that is in the third group and third period, according to the periodic table. Aluminum is a metal that has medium chemical activity. Also in its compounds, amphoteric properties can be observed. The atomic mass of aluminum is twenty-six grams per mole.

Physical characteristic of aluminum

Under normal conditions, it is a solid. The formula for aluminum is very simple. It consists of atoms (do not unite into molecules), which are built with the help of a crystal lattice into a continuous substance. Aluminum color - silver-white. In addition, it has a metallic luster, like all other substances of this group. The color of aluminum used in industry may vary due to the presence of impurities in the alloy. It is a fairly light metal.

Its density is 2.7 g / cm3, that is, it is approximately three times lighter than iron. In this, it can only yield to magnesium, which is even lighter than the metal in question. The hardness of aluminum is quite low. In it, it is inferior to most metals. The hardness of aluminum is only two. Therefore, to strengthen it, harder ones are added to alloys based on this metal.

The melting of aluminum occurs at a temperature of only 660 degrees Celsius. And it boils when heated to a temperature of two thousand four hundred and fifty-two degrees Celsius. It is a very ductile and fusible metal. The physical characteristics of aluminum do not end there. I would also like to note that this metal has the best electrical conductivity after copper and silver.

Prevalence in nature

Aluminum, the technical characteristics of which we have just reviewed, is quite common in the environment. It can be observed in the composition of many minerals. The element aluminum is the fourth most common element in nature. It is almost nine percent in the earth's crust. The main minerals in which its atoms are present are bauxite, corundum, cryolite. The first is a rock, which consists of oxides of iron, silicon and the metal in question, and water molecules are also present in the structure. It has a heterogeneous color: fragments of gray, reddish-brown and other colors, which depend on the presence of various impurities. From thirty to sixty percent of this breed is aluminum, the photo of which can be seen above. In addition, corundum is a very common mineral in nature.

This is aluminum oxide. Its chemical formula is Al2O3. It can be red, yellow, blue or brown. Its hardness on the Mohs scale is nine units. The varieties of corundum include well-known sapphires and rubies, leucosapphires, as well as padparadscha (yellow sapphire).

Cryolite is a mineral that has a more complex chemical formula. It consists of aluminum and sodium fluorides - AlF3.3NaF. It looks like a colorless or grayish stone with a low hardness - only three on the Mohs scale. In the modern world, it is synthesized artificially in the laboratory. It is used in metallurgy.

Aluminum can also be found in nature in the composition of clays, the main components of which are oxides of silicon and the metal in question, associated with water molecules. In addition, this chemical element can be observed in the composition of nephelines, the chemical formula of which is as follows: KNa34.

Receipt

The characterization of aluminum involves consideration of methods for its synthesis. There are several methods. The production of aluminum by the first method occurs in three stages. The last of these is the electrolysis procedure on the cathode and carbon anode. To carry out such a process, aluminum oxide is required, as well as auxiliary substances such as cryolite (formula - Na3AlF6) and calcium fluoride (CaF2). In order for the process of decomposition of aluminum oxide dissolved in water to occur, it must be heated together with molten cryolite and calcium fluoride to a temperature of at least nine hundred and fifty degrees Celsius, and then a current of eighty thousand amperes and a voltage of five- eight volts. Thus, as a result of this process, aluminum will settle on the cathode, and oxygen molecules will collect on the anode, which, in turn, oxidize the anode and turn it into carbon dioxide. Before carrying out this procedure, bauxite, in the form of which aluminum oxide is mined, is preliminarily cleaned of impurities, and also goes through the process of its dehydration.

The production of aluminum in the manner described above is very common in metallurgy. There is also a method invented in 1827 by F. Wehler. It lies in the fact that aluminum can be mined using a chemical reaction between its chloride and potassium. It is possible to carry out such a process only by creating special conditions in the form of a very high temperature and vacuum. So, from one mole of chloride and the same volume of potassium, one mole of aluminum and three moles as a by-product can be obtained. This reaction can be written as the following equation: АІСІ3 + 3К = АІ + 3КІ. This method has not gained much popularity in metallurgy.

Characteristics of aluminum in terms of chemistry

As mentioned above, this is a simple substance that consists of atoms that are not combined into molecules. Similar structures form almost all metals. Aluminum has a fairly high chemical activity and strong reducing properties. The chemical characterization of aluminum will begin with a description of its reactions with other simple substances, and then interactions with complex inorganic compounds will be described.

Aluminum and simple substances

These include, first of all, oxygen - the most common compound on the planet. Twenty-one percent of the Earth's atmosphere consists of it. The reactions of a given substance with any other are called oxidation, or combustion. It usually occurs at high temperatures. But in the case of aluminum, oxidation is possible under normal conditions - this is how an oxide film is formed. If this metal is crushed, it will burn, while releasing a large amount of energy in the form of heat. To carry out the reaction between aluminum and oxygen, these components are needed in a molar ratio of 4:3, resulting in two parts of the oxide.

This chemical interaction is expressed as the following equation: 4АІ + 3О2 = 2АІО3. Reactions of aluminum with halogens are also possible, which include fluorine, iodine, bromine and chlorine. The names of these processes come from the names of the corresponding halogens: fluorination, iodination, bromination and chlorination. These are typical addition reactions.

For example, we give the interaction of aluminum with chlorine. This kind of process can only occur in the cold.

So, taking two moles of aluminum and three moles of chlorine, we get as a result two moles of chloride of the metal in question. The equation for this reaction is as follows: 2АІ + 3СІ = 2АІСІ3. In the same way, aluminum fluoride, its bromide and iodide can be obtained.

With sulfur, the substance in question reacts only when heated. To carry out the interaction between these two compounds, you need to take them in molar proportions of two to three, and one part of aluminum sulfide is formed. The reaction equation has the following form: 2Al + 3S = Al2S3.

In addition, at high temperatures, aluminum interacts with carbon, forming a carbide, and with nitrogen, forming a nitride. The following equations of chemical reactions can be cited as an example: 4AI + 3C = AI4C3; 2Al + N2 = 2AlN.

Interaction with complex substances

These include water, salts, acids, bases, oxides. With all these chemical compounds, aluminum reacts in different ways. Let's take a closer look at each case.

Reaction with water

Aluminum interacts with the most common complex substance on Earth when heated. This happens only in the case of preliminary removal of the oxide film. As a result of the interaction, amphoteric hydroxide is formed, and hydrogen is also released into the air. Taking two parts of aluminum and six parts of water, we get hydroxide and hydrogen in molar proportions of two to three. The equation of this reaction is written as follows: 2АІ + 6Н2О = 2АІ (ОН) 3 + 3Н2.

Interaction with acids, bases and oxides

Like other active metals, aluminum is able to enter into a substitution reaction. In doing so, it can displace hydrogen from an acid or a cation of a more passive metal from its salt. As a result of such interactions, an aluminum salt is formed, and hydrogen is released (in the case of an acid) or a pure metal precipitates (one that is less active than the one under consideration). In the second case, the restorative properties that were mentioned above are manifested. An example is the interaction of aluminum with which aluminum chloride is formed and hydrogen is released into the air. This kind of reaction is expressed as the following equation: 2AI + 6HCI = 2AICI3 + 3H2.

An example of the interaction of aluminum with salt is its reaction with. Taking these two components, we will eventually get pure copper, which will precipitate. With acids such as sulfuric and nitric, aluminum reacts in a peculiar way. For example, when aluminum is added to a dilute solution of nitrate acid in a molar ratio of eight parts to thirty, eight parts of the nitrate of the metal in question, three parts of nitric oxide and fifteen parts of water are formed. The equation for this reaction is written as follows: 8Al + 30HNO3 = 8Al(NO3)3 + 3N2O + 15H2O. This process occurs only in the presence of high temperature.

If we mix aluminum and a weak solution of sulfate acid in molar proportions of two to three, we get the sulfate of the metal in question and hydrogen in a ratio of one to three. That is, an ordinary substitution reaction will occur, as is the case with other acids. For clarity, we present the equation: 2Al + 3H2SO4 = Al2(SO4)3 + 3H2. However, with a concentrated solution of the same acid, everything is more complicated. Here, as in the case of nitrate, a by-product is formed, but not in the form of oxide, but in the form of sulfur, and water. If we take the two components we need in a molar ratio of two to four, then as a result we get one part of the salt of the metal in question and sulfur, as well as four of water. This chemical interaction can be expressed using the following equation: 2Al + 4H2SO4 = Al2(SO4)3 + S + 4H2O.

In addition, aluminum is able to react with alkali solutions. To carry out such a chemical interaction, you need to take two moles of the metal in question, the same amount or potassium, as well as six moles of water. As a result, substances such as sodium or potassium tetrahydroxoaluminate are formed, as well as hydrogen, which is released as a gas with a pungent odor in molar proportions of two to three. This chemical reaction can be represented as the following equation: 2AI + 2KOH + 6H2O = 2K[AI(OH)4] + 3H2.

And the last thing to consider is the patterns of aluminum interaction with some oxides. The most common and used case is the Beketov reaction. It, like many others discussed above, occurs only at high temperatures. So, for its implementation, it is necessary to take two moles of aluminum and one mole of ferrum oxide. As a result of the interaction of these two substances, we obtain aluminum oxide and free iron in the amount of one and two moles, respectively.

The use of the metal in question in industry

Note that the use of aluminum is a very common occurrence. First of all, the aviation industry needs it. Along with this, alloys based on the metal in question are also used. We can say that the average aircraft is 50% aluminum alloys, and its engine is 25%. Also, the use of aluminum is carried out in the process of manufacturing wires and cables due to its excellent electrical conductivity. In addition, this metal and its alloys are widely used in the automotive industry. The bodies of cars, buses, trolleybuses, some trams, as well as ordinary and electric train cars are made of these materials.

It is also used for smaller purposes, for example, for the production of packaging for food and other products, dishes. In order to make silver paint, a powder of the metal in question is needed. Such paint is needed in order to protect iron from corrosion. We can say that aluminum is the second most commonly used metal in industry after ferrum. Its compounds and itself are often used in the chemical industry. This is due to the special chemical properties of aluminum, including its reducing properties and the amphoteric nature of its compounds. The hydroxide of the considered chemical element is necessary for water purification. In addition, it is used in medicine during the production of vaccines. It can also be found in some plastics and other materials.

Role in nature

As already mentioned above, aluminum is found in large quantities in the earth's crust. It is especially important for living organisms. Aluminum is involved in the regulation of growth processes, forms connective tissues, such as bone, ligamentous and others. Thanks to this microelement, the processes of regeneration of body tissues are carried out faster. Its deficiency is characterized by the following symptoms: developmental and growth disorders in children, in adults - chronic fatigue, reduced performance, impaired coordination of movements, slowdown in tissue regeneration, muscle weakness, especially in the limbs. This phenomenon can occur if you eat too few foods containing this trace element.

However, a more common problem is an excess of aluminum in the body. In this case, the following symptoms are often observed: nervousness, depression, sleep disturbances, memory loss, stress resistance, softening of the musculoskeletal system, which can lead to frequent fractures and sprains. With a prolonged excess of aluminum in the body, problems often arise in the work of almost every organ system.

A number of reasons can lead to this phenomenon. First of all, it has long been proven by scientists that dishes made from the metal in question are unsuitable for cooking food in it, since at high temperatures part of the aluminum gets into food, and as a result, you consume much more of this microelement than the body needs.

The second reason is the regular use of cosmetics containing the metal in question or its salts. Before using any product, you need to carefully read its composition. Cosmetics are no exception.

The third reason is taking drugs that contain a lot of aluminum for a long time. As well as the improper use of vitamins and nutritional supplements, which include this microelement.

Now let's figure out which products contain aluminum in order to regulate your diet and organize the menu correctly. First of all, these are carrots, processed cheeses, wheat, alum, potatoes. From fruits, avocados and peaches are recommended. In addition, white cabbage, rice, and many medicinal herbs are rich in aluminum. Also, the cations of the metal in question can be contained in drinking water. To avoid an increased or decreased content of aluminum in the body (however, just like any other trace element), you need to carefully monitor your diet and try to make it as balanced as possible.

Aluminum

Aluminum- a chemical element of group III of the periodic system of Mendeleev (atomic number 13, atomic mass 26.98154). In most compounds, aluminum is trivalent, but at high temperatures it can also exhibit an oxidation state of +1. Of the compounds of this metal, the most important is Al 2 O 3 oxide.

Aluminum- silver-white metal, light (density 2.7 g / cm 3), ductile, good conductor of electricity and heat, melting point 660 ° C. It is easily drawn into wire and rolled into thin sheets. Aluminum is chemically active (in air it is covered with a protective oxide film - aluminum oxide.) Reliably protects the metal from further oxidation. But if aluminum powder or aluminum foil is heated strongly, the metal burns with a blinding flame, turning into aluminum oxide. Aluminum dissolves even in dilute hydrochloric and sulfuric acids, especially when heated. But in highly dilute and concentrated cold nitric acid, aluminum does not dissolve. When aqueous solutions of alkalis act on aluminum, the oxide layer dissolves, and aluminates are formed - salts containing aluminum in the composition of the anion:

Al 2 O 3 + 2NaOH + 3H 2 O \u003d 2Na.

Aluminum, devoid of a protective film, interacts with water, displacing hydrogen from it:

2Al + 6H 2 O \u003d 2Al (OH) 3 + 3H 2

The resulting aluminum hydroxide reacts with an excess of alkali, forming hydroxoaluminate:

Al (OH) 3 + NaOH \u003d Na.

The overall equation for the dissolution of aluminum in an aqueous solution of alkali has the following form:

2Al + 2NaOH + 6H 2 O \u003d 2Na + 3H 2.

Aluminum actively interacts with halogens. Aluminum hydroxide Al(OH) 3 is a white, translucent, gelatinous substance.

The earth's crust contains 8.8% aluminum. It is the third most abundant element in nature after oxygen and silicon, and the first among metals. It is a part of clays, feldspars, micas. Several hundred Al minerals are known (aluminosilicates, bauxites, alunites, and others). The most important mineral of aluminum - bauxite contains 28-60% of alumina - aluminum oxide Al 2 O 3 .

In its pure form, aluminum was first obtained by the Danish physicist H. Oersted in 1825, although it is the most common metal in nature.

Aluminum production is carried out by electrolysis of alumina Al 2 O 3 in NaAlF 4 cryolite melt at a temperature of 950 °C.

Aluminum is used in aviation, construction, mainly in the form of aluminum alloys with other metals, electrical engineering (copper substitute in the manufacture of cables, etc.), food industry (foil), metallurgy (alloy additive), aluminothermy, etc.

Aluminum density, specific gravity and other characteristics.

Density - 2,7*10 3 kg/m 3 ;

Specific gravity - 2,7 G/ cm 3;

Specific heat at 20°C - 0.21 cal/deg;

Melting temperature - 658.7°C;

Specific heat capacity of melting - 76.8 cal/deg;

Boiling temperature - 2000°C ;

Relative volume change during melting (ΔV/V) - 6,6%;

Linear expansion coefficient(at approx. 20°C) :

- 22.9 * 10 6 (1 / deg);

Thermal conductivity coefficient of aluminum - 180 kcal / m * hour * hail;

Moduli of elasticity of aluminum and Poisson's ratio

Reflection of light by aluminum

The numbers given in the table show what percentage of light incident perpendicular to the surface is reflected from it.

ALUMINUM OXIDE Al 2 O 3

Aluminum oxide Al 2 O 3, also called alumina, occurs naturally in crystalline form, forming the mineral corundum. Corundum has a very high hardness. Its transparent crystals, colored in red or blue, are precious stones - ruby and sapphire. Currently, rubies are obtained artificially by fusing with alumina in an electric furnace. They are used not so much for jewelry as for technical purposes, for example, for the manufacture of parts for precision instruments, stones in watches, etc. Ruby crystals containing a small impurity of Cr 2 O 3 are used as quantum generators - lasers that create a directed beam of monochromatic radiation.

Corundum and its fine-grained variety, containing a large amount of impurities - emery, are used as abrasive materials.

ALUMINUM PRODUCTION

The main raw material for aluminum production are bauxites containing 32-60% alumina Al 2 O 3 . The most important aluminum ores also include alunite and nepheline. Russia has significant reserves of aluminum ores. In addition to bauxites, large deposits of which are located in the Urals and Bashkiria, nepheline, mined on the Kola Peninsula, is a rich source of aluminum. A lot of aluminum is also found in the deposits of Siberia.

Aluminum is obtained from aluminum oxide Al 2 O 3 by the electrolytic method. The aluminum oxide used for this must be sufficiently pure, since impurities are removed from smelted aluminum with great difficulty. Purified Al 2 O 3 is obtained by processing natural bauxite.

The main starting material for the production of aluminum is aluminum oxide. It does not conduct electricity and has a very high melting point (about 2050 °C), so it requires too much energy.

It is necessary to reduce the melting point of aluminum oxide to at least 1000 o C. This method was found in parallel by the Frenchman P. Eru and the American C. Hall. They found that alumina dissolves well in molten cryolite, a mineral of AlF 3 composition. 3NaF. This melt is subjected to electrolysis at a temperature of only about 950 ° C in aluminum production. The reserves of cryolite in nature are insignificant, so synthetic cryolite was created, which significantly reduced the cost of aluminum production.

Hydrolysis is subjected to a molten mixture of cryolite Na 3 and aluminum oxide. A mixture containing about 10 weight percent Al 2 O 3 melts at 960 °C and has the electrical conductivity, density and viscosity most favorable to the process. To further improve these characteristics, additives AlF 3 , CaF 2 and MgF 2 are introduced into the composition of the mixture. This makes electrolysis possible at 950 °C.

The electrolyser for aluminum smelting is an iron casing lined with refractory bricks from the inside. Its bottom (under), assembled from blocks of compressed coal, serves as a cathode. Anodes (one or more) are located on top: these are aluminum frames filled with coal briquettes. In modern plants, electrolyzers are installed in series; each series consists of 150 or more cells.

During electrolysis, aluminum is released at the cathode, and oxygen is released at the anode. Aluminum, which has a higher density than the original melt, is collected at the bottom of the electrolyzer, from where it is periodically discharged. As the metal is released, new portions of aluminum oxide are added to the melt. The oxygen released during electrolysis interacts with the carbon of the anode, which burns out, forming CO and CO 2 .

The first aluminum plant in Russia was built in 1932 in Volkhov.

ALUMINUM ALLOYS

Alloys, which increase the strength and other properties of aluminum, are obtained by introducing alloying additives into it, such as copper, silicon, magnesium, zinc, and manganese.

Duralumin(duralumin, duralumin, from the name of the German city where the industrial production of the alloy was started). Aluminum alloy (base) with copper (Cu: 2.2-5.2%), magnesium (Mg: 0.2-2.7%) manganese (Mn: 0.2-1%). It is subjected to hardening and aging, often clad with aluminum. It is a structural material for aviation and transport engineering.

Silumin- light cast aluminum alloys (base) with silicon (Si: 4-13%), sometimes up to 23% and some other elements: Cu, Mn, Mg, Zn, Ti, Be). They produce parts of complex configuration, mainly in the automotive and aircraft industries.

magnalia- aluminum alloys (base) with magnesium (Mg: 1-13%) and other elements with high corrosion resistance, good weldability, high ductility. They make shaped castings (casting magnals), sheets, wire, rivets, etc. (deformable magnalia).

The main advantages of all aluminum alloys are their low density (2.5-2.8 g / cm 3), high strength (per unit weight), satisfactory resistance to atmospheric corrosion, comparative low cost and ease of production and processing.

Aluminum alloys are used in rocket technology, in aircraft, auto, ship and instrument making, in the production of utensils, sporting goods, furniture, advertising and other industries.

In terms of breadth of application, aluminum alloys rank second after steel and cast iron.

Aluminum is one of the most common additives in alloys based on copper, magnesium, titanium, nickel, zinc, and iron.

Aluminum is also used for aluminizing (aluminizing)- saturation of the surface of steel or cast iron products with aluminum in order to protect the base material from oxidation during strong heating, i.e. increase heat resistance (up to 1100 °C) and resistance to atmospheric corrosion.

Aluminum is an element of the 13th group of the periodic table of chemical elements, the third period, with atomic number 13. It belongs to the group of light metals. The most common metal and the third most common chemical element in the earth's crust (after oxygen and silicon).

The simple substance aluminum is a light, paramagnetic silver-white metal, easily molded, cast, and machined. Aluminum has a high thermal and electrical conductivity, resistance to corrosion due to the rapid formation of strong oxide films that protect the surface from further interaction.

The modern method of obtaining, the Hall-Héroult process. It consists in the dissolution of aluminum oxide Al2O3 in a melt of Na3AlF6 cryolite, followed by electrolysis using consumable coke or graphite anode electrodes. This method of obtaining requires very large amounts of electricity, and therefore received industrial application only in the 20th century.

Laboratory method for obtaining aluminum: reduction of anhydrous aluminum chloride with metallic potassium (the reaction proceeds when heated without air):

Silver-white metal, light, density - 2.7 g / cm³, melting point for technical aluminum - 658 ° C, for high-purity aluminum - 660 ° C, high ductility: for technical - 35%, for pure - 50% , rolled into a thin sheet and even foil. Aluminum has high electrical conductivity (37 106 S/m) and thermal conductivity (203.5 W/(m K)), 65%, has high light reflectivity.

Aluminum forms alloys with almost all metals. The best known are alloys with copper and magnesium (duralumin) and silicon (silumin).

In terms of prevalence in the earth's crust, the Earth occupies the 1st place among metals and the 3rd place among the elements, second only to oxygen and silicon. The mass concentration of aluminum in the earth's crust, according to various researchers, is estimated at 7.45 to 8.14%. In nature, aluminum, due to its high chemical activity, occurs almost exclusively in the form of compounds.

Natural aluminum consists almost entirely of a single stable isotope, 27Al, with negligible traces of 26Al, the longest-lived radioactive isotope with a half-life of 720,000 years, produced in the atmosphere by the splitting of 40Ar argon nuclei by high-energy cosmic ray protons.

Under normal conditions, aluminum is covered with a thin and strong oxide film and therefore does not react with classical oxidizing agents: with H2O (t°), O2, HNO3 (without heating). Due to this, aluminum is practically not subject to corrosion and therefore is widely demanded by modern industry. However, when the oxide film is destroyed (for example, upon contact with solutions of ammonium salts NH4 +, hot alkalis, or as a result of amalgamation), aluminum acts as an active reducing metal. It is possible to prevent the formation of an oxide film by adding metals such as gallium, indium or tin to aluminum. In this case, the surface of aluminum is wetted by low-melting eutectics based on these metals.

Easily reacts with simple substances:

with oxygen to form alumina:

with halogens (except fluorine), forming chloride, bromide or aluminum iodide:

reacts with other non-metals when heated:

with fluorine, forming aluminum fluoride:

with sulfur, forming aluminum sulfide:

with nitrogen to form aluminum nitride:

with carbon, forming aluminum carbide:

Aluminum sulfide and aluminum carbide are completely hydrolyzed:

With complex substances:

with water (after removing the protective oxide film, for example, by amalgamation or hot alkali solutions):

with alkalis (with the formation of tetrahydroxoaluminates and other aluminates):

Easily soluble in hydrochloric and dilute sulfuric acids:

When heated, it dissolves in acids - oxidizing agents that form soluble aluminum salts:

restores metals from their oxides (aluminothermy):

44. Aluminum compounds, their amphoteric properties

The electronic configuration of the external level of aluminum is … 3s23p1.

In the excited state, one of the s-electrons passes to a free cell of the p-sublevel, this state corresponds to valence III and the oxidation state +3. There are free d-sublevels in the outer electron layer of the aluminum atom.

The most important natural compounds are aluminosilicates:

white clay Al2O3 ∙ 2SiO2 ∙ 2H2O, feldspar K2O ∙ Al2O3 ∙ 6SiO2, mica K2O ∙ Al2O3 ∙ 6SiO2 ∙ H2O

Of the other natural forms of aluminum occurrence, bauxites А12Оз ∙ nН2О, corundum minerals А12Оз and cryolite А1Fз ∙3NaF are of the greatest importance.

Lightweight, silvery-white, ductile metal, conducts electricity and heat well.

In air, aluminum is covered with the thinnest (0.00001 mm), but very dense oxide film, which protects the metal from further oxidation and gives it a matte appearance.

Aluminum oxide А12О3

White solid, insoluble in water, melting point 2050°C.

Natural A12O3 is the mineral corundum. Transparent colored crystals of corundum - red ruby - contains an admixture of chromium - and blue sapphire - an admixture of titanium and iron - precious stones. They are also obtained artificially and used for technical purposes, for example, for the manufacture of parts for precision instruments, stones in watches, etc.

Chemical properties

Aluminum oxide exhibits amphoteric properties

1. interaction with acids

А12О3 + 6HCl = 2AlCl3 + 3H2O

2. interaction with alkalis

А12О3 + 2NaOH – 2NaAlO2 + H2O

Al2O3 + 2NaOH + 5H2O = 2Na

3. When a mixture of oxide of the corresponding metal with aluminum powder is heated, a violent reaction occurs, leading to the release of free metal from the taken oxide. The reduction method with Al (aluminum) is often used to obtain a number of elements (Cr, Mn, V, W, etc.) in a free state

2A1 + WO3 = A12Oz + W

4. interaction with salts having a strongly alkaline environment due to hydrolysis

Al2O3 + Na2CO3 = 2 NaAlO2 + CO2

Aluminum hydroxide A1(OH)3

Al(OH)3 is a voluminous white gelatinous precipitate, practically insoluble in water, but easily soluble in acids and strong alkalis. It therefore has an amphoteric character.

Aluminum hydroxide is obtained by the exchange reaction of soluble aluminum salts with alkalis.

AlCl3 + 3NaOH = Al(OH)3↓ + 3NaCl

Al3+ + 3OH- = Al(OH)3↓

This reaction can be used as a qualitative one for the Al3+ ion

Chemical properties

1. interaction with acids

Al(OH)3 +3HCl = 2AlCl3 + 3H2O

2. when interacting with strong alkalis, the corresponding aluminates are formed:

NaOH + A1(OH)3 = Na

3. thermal decomposition

2Al(OH)3 = Al2O3 + 3H2O

Aluminum salts undergo cation hydrolysis, acidic environment (pH< 7)

Al3+ + H+OH- ↔ AlOH2+ + H+

Al(NO3)3 + H2O↔ AlOH(NO3)2 + HNO3

Soluble salts of aluminum and weak acids undergo complete (irreversible hydrolysis)

Al2S3+ 3H2O = 2Al(OH)3 +3H2S

Aluminum oxide Al2O3 - is part of some antacids (for example, Almagel), used for increased acidity of gastric juice.

КAl(SO4)3 12H2О - potassium alum is used in medicine for the treatment of skin diseases, as a hemostatic agent. It is also used as a tannin in the leather industry.

(CH3COO)3Al - Burov's Liquid - 8% solution of aluminum acetate has an astringent and anti-inflammatory effect, in high concentrations it has moderate antiseptic properties. It is used in diluted form for rinsing, lotions, for inflammatory diseases of the skin and mucous membranes.

AlCl3 - used as a catalyst in organic synthesis.

Al2(SO4)3 18 H20 - used in water treatment.

Obtaining potassium alum

Aluminum(lat. Aluminum), - in the periodic system, aluminum is in the third period, in the main subgroup of the third group. Core Charge +13. The electronic structure of the atom is 1s 2 2s 2 2p 6 3s 2 3p 1 . The metal atomic radius is 0.143 nm, the covalent one is 0.126 nm, the conditional radius of the Al 3+ ion is 0.057 nm. Ionization energy Al - Al + 5.99 eV.

The most characteristic oxidation state of the aluminum atom is +3. A negative oxidation state is rare. There are free d-sublevels in the outer electron layer of the atom. Due to this, its coordination number in compounds can be not only 4 (AlCl 4-, AlH 4-, aluminosilicates), but also 6 (Al 2 O 3, 3+).

History reference. The name aluminum comes from lat. alumen - so back in 500 BC. called aluminum alum, which was used as a mordant in the dyeing of fabrics and for tanning leather. The Danish scientist H. K. Oersted in 1825, acting with an amalgam of potassium on anhydrous AlCl 3 and then driving away mercury, obtained relatively pure aluminum. The first industrial method for the production of aluminum was proposed in 1854 by the French chemist A.E. St. Clair Deville: the method consisted in the reduction of aluminum and sodium double chloride Na 3 AlCl 6 with sodium metal. Similar in color to silver, aluminum was very expensive at first. From 1855 to 1890 only 200 tons of aluminum were produced. The modern method of producing aluminum by electrolysis of a cryolite-alumina melt was developed in 1886 simultaneously and independently by C. Hall in the USA and P. Héroux in France.

Being in nature

Aluminum is the most abundant metal in the earth's crust. It accounts for 5.5–6.6 mol. share% or 8 wt.%. Its main mass is concentrated in aluminosilicates. An extremely common product of the destruction of the rocks formed by them is clay, the main composition of which corresponds to the formula Al 2 O 3. 2SiO2. 2H 2 O. Of the other natural forms of aluminum, bauxite Al 2 O 3 is of the greatest importance. xH 2 O and minerals corundum Al 2 O 3 and cryolite AlF 3 . 3NaF.

Receipt

At present, aluminum is produced in industry by electrolysis of a solution of alumina Al 2 O 3 in molten cryolite. Al 2 O 3 must be sufficiently pure, since impurities are removed from smelted aluminum with great difficulty. The melting temperature of Al 2 O 3 is about 2050 o C, and that of cryolite is 1100 o C. A molten mixture of cryolite and Al 2 O 3 containing about 10 wt.% Al 2 O 3 is subjected to electrolysis, which melts at 960 o C and has electrical conductivity , density and viscosity, the most favorable for the process. By adding AlF 3 , CaF 2 and MgF 2 electrolysis is possible at 950°C.

The electrolytic cell for aluminum smelting is an iron casing lined with refractory bricks from the inside. Its bottom (under), assembled from blocks of compressed coal, serves as a cathode. The anodes are located on top: these are aluminum frames filled with coal briquettes.

Al 2 O 3 \u003d Al 3+ + AlO 3 3-

Liquid aluminum is released at the cathode:

Al 3+ + 3e - \u003d Al

Aluminum is collected at the bottom of the furnace, from where it is periodically released. Oxygen is released at the anode:

4AlO 3 3- - 12e - \u003d 2Al 2 O 3 + 3O 2

Oxygen oxidizes graphite to carbon oxides. As the carbon burns, the anode is built up.

Aluminum is also used as an alloying addition to many alloys to give them heat resistance.

Physical properties of aluminum. Aluminum combines a very valuable set of properties: low density, high thermal and electrical conductivity, high ductility and good corrosion resistance. It can be easily forged, stamped, rolled, drawn. Aluminum is well welded by gas, contact and other types of welding. The aluminum lattice is face-centered cubic with parameter a = 4.0413 Å. The properties of aluminum, like those of all metals, depend to a large extent on its purity. Properties of high purity aluminum (99.996%): density (at 20 °C) 2698.9 kg/m 3 ; t pl 660.24 °C; t bale about 2500 °C; thermal expansion coefficient (from 20 ° to 100 ° C) 23.86 10 -6; thermal conductivity (at 190 °C) 343 W/m K, specific heat capacity (at 100 °C) 931.98 J/kg K. ; electrical conductivity with respect to copper (at 20 °C) 65.5%. Aluminum has low strength (tensile strength 50–60 MN/m2), hardness (170 MN/m2 according to Brinell) and high ductility (up to 50%). During cold rolling, the tensile strength of Aluminum increases to 115 MN/m 2 , hardness - up to 270 MN/m 2 , relative elongation decreases to 5% (1 MN/m 2 ~ and 0.1 kgf/mm 2). Aluminum is well polished, anodized and has a high reflectivity close to silver (it reflects up to 90% of the incident light energy). Possessing a high affinity for oxygen, aluminum in air is covered with a thin, but very strong oxide film Al 2 O 3 , which protects the metal from further oxidation and determines its high anti-corrosion properties. The strength of the oxide film and its protective effect greatly decrease in the presence of impurities of mercury, sodium, magnesium, copper, etc. Aluminum is resistant to atmospheric corrosion, sea and fresh water, practically does not interact with concentrated or highly diluted nitric acid, with organic acids, food products.

Chemical properties

When finely divided aluminum is heated, it burns vigorously in air. Its interaction with sulfur proceeds similarly. With chlorine and bromine, the combination occurs already at ordinary temperature, with iodine - when heated. At very high temperatures, aluminum also combines directly with nitrogen and carbon. On the contrary, it does not interact with hydrogen.

Aluminum is quite resistant to water. But if the protective effect of the oxide film is removed mechanically or by amalgamation, then an energetic reaction occurs:

Highly dilute, as well as very concentrated HNO3 and H2SO4, have almost no effect on aluminum (in the cold), while at medium concentrations of these acids, it gradually dissolves. Pure aluminum is quite stable with respect to hydrochloric acid, but the usual technical metal dissolves in it.

Under the action of alkali aqueous solutions on aluminum, the oxide layer dissolves, and aluminates are formed - salts containing aluminum in the composition of the anion:

Al 2 O 3 + 2NaOH + 3H 2 O \u003d 2Na

Aluminum, devoid of a protective film, interacts with water, displacing hydrogen from it:

2Al + 6H 2 O \u003d 2Al (OH) 3 + 3H 2

The resulting aluminum hydroxide reacts with an excess of alkali, forming hydroxoaluminate:

Al(OH) 3 + NaOH = Na

The overall equation for the dissolution of aluminum in an aqueous solution of alkali:

2Al + 2NaOH + 6H 2 O = 2Na + 3H 2

Aluminum noticeably dissolves in solutions of salts that have an acidic or alkaline reaction due to their hydrolysis, for example, in a solution of Na 2 CO 3 .

In a series of stresses, it is located between Mg and Zn. In all of its stable compounds, aluminum is trivalent.

The combination of aluminum with oxygen is accompanied by an enormous release of heat (1676 kJ/mol Al 2 O 3), much greater than that of many other metals. In view of this, when a mixture of the corresponding metal oxide with aluminum powder is heated, a violent reaction occurs, leading to the release of free metal from the taken oxide. The reduction method with Al (aluminum) is often used to obtain a number of elements (Cr, Mn, V, W, etc.) in a free state.

Aluminothermy is sometimes used for welding individual steel parts, in particular the joints of tram rails. The mixture used ("termite") usually consists of fine powders of aluminum and Fe 3 O 4 . It is ignited with a fuse from a mixture of Al and BaO 2. The main reaction goes according to the equation:

8Al + 3Fe 3 O 4 = 4Al 2 O 3 + 9Fe + 3350 kJ

Moreover, the temperature develops around 3000 o C.

Aluminum oxide is a white, very refractory (mp 2050 o C) and water-insoluble mass. Natural Al 2 O 3 (corundum mineral), as well as artificially obtained and then strongly calcined, are distinguished by high hardness and insolubility in acids. Al 2 O 3 (so-called alumina) can be converted into a soluble state by fusion with alkalis.

Natural corundum, normally contaminated with iron oxide, is used for the manufacture of grinding wheels, bars, etc. due to its extreme hardness. In finely crushed form, it is called emery and is used to clean metal surfaces and make sandpaper. For the same purposes, Al 2 O 3 is often used, obtained by fusing bauxite (technical name - alund).

Transparent colored corundum crystals - red ruby - an admixture of chromium - and blue sapphire - an admixture of titanium and iron - precious stones. They are also obtained artificially and used for technical purposes, for example, for the manufacture of parts for precision instruments, stones in watches, etc. Ruby crystals containing a small impurity of Cr 2 O 3 are used as quantum generators - lasers that create a directed beam of monochromatic radiation.

Due to the insolubility of Al 2 O 3 in water, the hydroxide Al(OH) 3 corresponding to this oxide can only be obtained indirectly from salts. The production of hydroxide can be represented as the following scheme. Under the action of alkalis, OH ions gradually replace 3+ water molecules in aquocomplexes:

3+ + OH - \u003d 2+ + H 2 O

2+ + OH - = + + H 2 O

OH - \u003d 0 + H 2 O

Al(OH) 3 is a voluminous white gelatinous precipitate, practically insoluble in water, but easily soluble in acids and strong alkalis. It therefore has an amphoteric character. However, its basic and especially acidic properties are rather weakly expressed. In excess of NH 4 OH, aluminum hydroxide is insoluble. One form of dehydrated hydroxide, aluminum gel, is used in engineering as an adsorbent.

When interacting with strong alkalis, the corresponding aluminates are formed:

NaOH + Al(OH) 3 = Na

Aluminates of the most active monovalent metals are highly soluble in water, but due to strong hydrolysis, their solutions are stable only in the presence of a sufficient excess of alkali. Aluminates produced from weaker bases are almost completely hydrolyzed in solution and therefore can only be obtained in a dry way (by alloying Al 2 O 3 with oxides of the corresponding metals). Metaaluminates are formed, which in their composition are produced from metaaluminum acid HAlO 2 . Most of them are insoluble in water.

Al(OH) 3 forms salts with acids. The derivatives of most strong acids are highly soluble in water, but are rather hydrolyzed, and therefore their solutions show an acidic reaction. Soluble salts of aluminum and weak acids are even more strongly hydrolyzed. Due to hydrolysis, sulfide, carbonate, cyanide and some other aluminum salts cannot be obtained from aqueous solutions.

In an aqueous medium, the Al 3+ anion is directly surrounded by six water molecules. Such a hydrated ion is somewhat dissociated according to the scheme:

3+ + H 2 O \u003d 2+ + OH 3 +

Its dissociation constant is 1. 10 -5 i.e. it is a weak acid (similar in strength to acetic acid). The octahedral environment of Al 3+ with six water molecules is also retained in crystalline hydrates of a number of aluminum salts.

Aluminosilicates can be considered as silicates, in which part of the silicon-oxygen tetrahedra SiO 4 4 - is replaced by aluminum-oxygen tetrahedra AlO 4 5- Of the aluminosilicates, feldspars are the most common, accounting for more than half of the mass of the earth's crust. Their main representatives are minerals

orthoclase K 2 Al 2 Si 6 O 16 or K 2 O . Al 2 O 3 . 6SiO2

albite Na 2 Al 2 Si 6 O 16 or Na 2 O . Al 2 O 3 . 6SiO2

anorthite CaAl 2 Si 2 O 8 or CaO. Al 2 O 3 . 2SiO2

The minerals of the mica group are very common, for example muscovite Kal 2 (AlSi 3 O 10) (OH) 2. Of great practical importance is the mineral nepheline (Na, K) 2, which is used to obtain alumina, soda products and cement. This production consists of the following operations: a) nepheline and limestone are sintered in tube furnaces at 1200°C:

(Na, K) 2 + 2CaCO 3 = 2CaSiO 3 + NaAlO 2 + KAlO 2 + 2CO 2

b) the resulting mass is leached with water - a solution of sodium and potassium aluminates and CaSiO 3 sludge are formed:

NaAlO 2 + KAlO 2 + 4H 2 O \u003d Na + K

c) CO 2 formed during sintering is passed through a solution of aluminates:

Na + K + 2CO 2 = NaHCO 3 + KHCO 3 + 2Al(OH) 3

d) heating Al (OH) 3 alumina is obtained:

2Al(OH) 3 \u003d Al 2 O 3 + 3H 2 O

e) by evaporation of the mother liquor, soda and potage are isolated, and the previously obtained sludge is used for the production of cement.

In the production of 1 t of Al 2 O 3, 1 t of soda products and 7.5 t of cement are obtained.

Some aluminosilicates have a loose structure and are capable of ion exchange. Such silicates - natural and especially artificial - are used for water softening. In addition, due to their highly developed surface, they are used as catalyst carriers, i.e. as materials impregnated with a catalyst.

Aluminum halides under normal conditions are colorless crystalline substances. In the series of aluminum halides, AlF 3 differs greatly in properties from its analogues. It is refractory, slightly soluble in water, chemically inactive. The main method for obtaining AlF 3 is based on the action of anhydrous HF on Al 2 O 3 or Al:

Al 2 O 3 + 6HF = 2AlF 3 + 3H 2 O

Aluminum compounds with chlorine, bromine and iodine are fusible, highly reactive and highly soluble not only in water, but also in many organic solvents. The interaction of aluminum halides with water is accompanied by a significant release of heat. In an aqueous solution, they are all highly hydrolyzed, but unlike typical non-metal acid halides, their hydrolysis is incomplete and reversible. Being noticeably volatile already under normal conditions, AlCl 3 , AlBr 3 and AlI 3 smoke in moist air (due to hydrolysis). They can be obtained by direct interaction of simple substances.

Vapor densities of AlCl 3 , AlBr 3 and AlI 3 at relatively low temperatures correspond more or less exactly to the doubled formulas - Al 2 Hal 6 . The spatial structure of these molecules corresponds to two tetrahedra with a common edge. Each aluminum atom is bonded to four halogen atoms, and each of the central halogen atoms is bonded to both aluminum atoms. Of the two bonds of the central halogen atom, one is donor-acceptor, with aluminum functioning as an acceptor.

With halide salts of a number of monovalent metals, aluminum halides form complex compounds, mainly of the M 3 and M types (where Hal is chlorine, bromine or iodine). The tendency to addition reactions is generally strongly pronounced in the halides under consideration. This is the reason for the most important technical application of AlCl 3 as a catalyst (in oil refining and in organic syntheses).

Of the fluoroaluminates, cryolite Na 3 has the greatest application (for the production of Al, F 2 , enamels, glass, etc.). The industrial production of artificial cryolite is based on the treatment of aluminum hydroxide with hydrofluoric acid and soda:

2Al(OH) 3 + 12HF + 3Na 2 CO 3 = 2Na 3 + 3CO 2 + 9H 2 O

Chloro-, bromo- and iodoaluminates are obtained by fusing aluminum trihalides with halides of the corresponding metals.

Although aluminum does not react chemically with hydrogen, aluminum hydride can be obtained indirectly. It is a white amorphous mass of composition (AlH 3) n . Decomposes when heated above 105 ° C with the release of hydrogen.

When AlH 3 interacts with basic hydrides in an ether solution, hydroaluminates are formed:

LiH + AlH 3 = Li

Hydridoaluminates are white solids. Rapidly decomposed by water. They are powerful restorers. Used (especially Li) in organic synthesis.

Aluminum sulfate Al 2 (SO 4) 3. 18H 2 O is obtained by the action of hot sulfuric acid on aluminum oxide or kaolin. It is used to purify water, as well as in the preparation of some types of paper.

Potassium alum KAl(SO 4) 2 . 12H 2 O is used in large quantities for tanning leather, as well as in dyeing as a mordant for cotton fabrics. In the latter case, the effect of alum is based on the fact that the aluminum hydroxide formed as a result of their hydrolysis is deposited in the fibers of the fabric in a finely dispersed state and, adsorbing the dye, firmly holds it on the fiber.

Of the other aluminum derivatives, mention should be made of its acetate (otherwise, the acetic acid salt) Al(CH 3 COO) 3, used in dyeing fabrics (as a mordant) and in medicine (lotions and compresses). Aluminum nitrate is easily soluble in water. Aluminum phosphate is insoluble in water and acetic acid, but soluble in strong acids and alkalis.

aluminum in the body. Aluminum is part of the tissues of animals and plants; in the organs of mammals, from 10 -3 to 10 -5% of aluminum (per crude substance) was found. Aluminum accumulates in the liver, pancreas and thyroid glands. In vegetable products, the aluminum content ranges from 4 mg per 1 kg of dry matter (potato) to 46 mg (yellow turnip), in animal products - from 4 mg (honey) to 72 mg per 1 kg of dry matter (beef). In the daily human diet, the aluminum content reaches 35-40 mg. There are known organisms - aluminum concentrators, for example, club mosses (Lycopodiaceae), containing up to 5.3% aluminum in the ash, mollusks (Helix and Lithorina), in the ashes of which 0.2–0.8% aluminum. Forming insoluble compounds with phosphates, aluminum disrupts the nutrition of plants (phosphate absorption by roots) and animals (phosphate absorption in the intestines).

Geochemistry of aluminum. The geochemical features of aluminum are determined by its high affinity for oxygen (in minerals, aluminum is included in oxygen octahedrons and tetrahedra), constant valency (3), and low solubility of most natural compounds. In endogenous processes during the solidification of magma and the formation of igneous rocks, aluminum enters the crystal lattice of feldspars, micas and other minerals - aluminosilicates. In the biosphere, aluminum is a weak migrant; it is scarce in organisms and the hydrosphere. In a humid climate, where the decaying remains of abundant vegetation form a lot of organic acids, aluminum migrates in soils and waters in the form of organomineral colloidal compounds; aluminum is adsorbed by colloids and precipitated in the lower part of soils. The bond between aluminum and silicon is partially broken and in places in the tropics minerals are formed - aluminum hydroxides - boehmite, diaspore, hydrargillite. Most of the aluminum is part of the aluminosilicates - kaolinite, beidellite and other clay minerals. Weak mobility determines the residual accumulation of aluminum in the weathering crust of the humid tropics. As a result, eluvial bauxites are formed. In past geological epochs, bauxites also accumulated in lakes and the coastal zone of the seas of tropical regions (for example, sedimentary bauxites of Kazakhstan). In the steppes and deserts, where there is little living matter, and the waters are neutral and alkaline, aluminum almost does not migrate. The migration of aluminum is most vigorous in volcanic areas, where highly acidic river and underground waters rich in aluminum are observed. In places of displacement of acidic waters with alkaline - marine (at the mouths of rivers and others), aluminum is deposited with the formation of bauxite deposits.

Aluminum Application. The combination of physical, mechanical and chemical properties of aluminum determines its wide application in almost all areas of technology, especially in the form of its alloys with other metals. In electrical engineering, Aluminum successfully replaces copper, especially in the production of massive conductors, for example, in overhead lines, high-voltage cables, switchgear busbars, transformers (the electrical conductivity of Aluminum reaches 65.5% of the electrical conductivity of copper, and it is more than three times lighter than copper; with a cross section that provides the same conductivity, the mass of aluminum wires is half that of copper wires). Ultra-pure Aluminum is used in the production of electrical capacitors and rectifiers, the operation of which is based on the ability of the aluminum oxide film to transmit electric current in only one direction. Ultra-pure aluminum, purified by zone melting, is used for the synthesis of type A III B V semiconductor compounds used for the production of semiconductor devices. Pure Aluminum is used in the production of various mirror reflectors. High-purity aluminum is used to protect metal surfaces from atmospheric corrosion (cladding, aluminum paint). Having a relatively low neutron absorption cross section, aluminum is used as a structural material in nuclear reactors.

Large-capacity aluminum tanks store and transport liquid gases (methane, oxygen, hydrogen, etc.), nitric and acetic acids, pure water, hydrogen peroxide and edible oils. Aluminum is widely used in food industry equipment and apparatus, for food packaging (in the form of foil), for the production of various household products. There has been a sharp increase in the consumption of aluminum for finishing buildings, architectural, transport and sports facilities.

In metallurgy, aluminum (besides alloys based on it) is one of the most common alloying additives in alloys based on Cu, Mg, Ti, Ni, Zn, and Fe. Aluminum is also used to deoxidize steel before pouring it into a mold, as well as in the processes of obtaining certain metals by aluminothermy. On the basis of aluminum, SAP (sintered aluminum powder) was created by powder metallurgy, which has high heat resistance at temperatures above 300 °C.

Aluminum is used in the production of explosives (ammonal, alumotol). Various aluminum compounds are widely used.

The production and consumption of aluminum is constantly growing, significantly outpacing the production of steel, copper, lead, and zinc in terms of growth rates.

List of used literature

1. V.A. Rabinovich, Z.Ya. Khavin "Concise Chemical Reference"

2. L.S. Guzey "Lectures on General Chemistry"

3. N.S. Akhmetov "General and inorganic chemistry"

4. B.V. Nekrasov "Textbook of General Chemistry"

5. N.L. Glinka "General Chemistry"

DEFINITION

Aluminum located in the third period, group III of the main (A) subgroup of the Periodic Table. This is the first p-element of the 3rd period.

Metal. Designation - Al. Ordinal number - 13. Relative atomic mass - 26.981 a.m.u.

The electronic structure of the aluminum atom

The aluminum atom consists of a positively charged nucleus (+13), inside which there are 13 protons and 14 neutrons. The nucleus is surrounded by three shells, along which 13 electrons move.

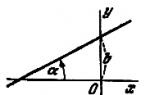

Rice. 1. Schematic representation of the structure of the aluminum atom.

The distribution of electrons in orbitals is as follows:

13Al) 2) 8) 3 ;

1s 2 2s 2 2p 6 3s 2 3p 1 .

There are three electrons on the outer energy level of aluminum, all electrons of the 3rd sublevel. The energy diagram takes the following form:

Theoretically, an excited state is possible for an aluminum atom due to the presence of a vacant 3 d-orbitals. However, electron depairing 3 s- sublevel does not actually occur.

Examples of problem solving

EXAMPLE 1