Astronomical instruments and observations with them. Optical telescopes - types and device. Types of telescopes How a telescope works

Designed to use it to observe distant celestial objects. If this word is translated from Greek into Russian, it will mean "I observe far away."

Novice amateur astronomers are certainly interested in how a telescope works and what types of these optical instruments exist. A beginner, having come to an optics store, often asks the seller: “How many times does this telescope magnify?” To some, the following statement may seem surprising, but the very formulation of the question is incorrect.

Isn't it a matter of magnification?

There are people who think that the more the telescope magnifies, the "cooler" it is. Someone believes that it brings distant objects closer to us. Both of these opinions are wrong. The main task of this optical instrument is to collect the radiation of the waves of the electromagnetic spectrum, which include the light that we see. By the way, the concept of electromagnetic radiation also includes other waves (radio, infrared, ultraviolet, X-ray, etc.). Modern telescopes can capture all of these ranges.

So, the essence of the functions of the telescope is not how many times it magnifies, but how much light it can collect. The more light the lens or mirror collects, the clearer the picture we need will be.

To create a good image, the optical system of a telescope concentrates light rays at one point. It's called focus. If the light is not focused in it, we will get a blurry picture.

What are telescopes?

How is a telescope made? There are several main types:

- . In the design of the refractor, only lenses are used. His work is based on the refraction of light rays;

- . They consist entirely of mirrors, while the telescope layout looks like this: the lens is the main mirror, and there is also a secondary one;

- or mixed type. They consist of both lenses and mirrors.

How refractors work

The lens of any refractor looks like a biconvex lens. Its task is to collect light rays and concentrate them at one point (focusing). We get an increase in the original image through the eyepiece. The lenses used in modern telescope models are complex optical systems. If we limit ourselves to using only one large lens, convex on both sides, this is fraught with strong errors in the resulting image.

First, initially, the rays of light cannot clearly gather at one point. This phenomenon is called spherical aberration, as a result of which it is impossible to obtain an image with the same sharpness in all its areas. When using hover, we can sharpen the center of the image, but we get blurry edges - and vice versa.

In addition to spherical, refractors also "sin" with chromatic aberration. The distortion of color perception occurs because the composition of the light emanating from space objects includes rays of a different color spectrum. When they pass through the lens, they cannot be refracted in the same way, therefore, they are scattered along different parts of the optical axis of the instrument. The result is a strong distortion of the color of the resulting image.

Opticians have learned well how to "fight" various kinds of aberrations. To this end, they manufacture optical systems of refractors, consisting of different lenses. Thus, the correction of the picture becomes real, but such work requires considerable effort.

How reflectors work

The appearance of reflecting telescopes in astronomy is not accidental, since the chromatic aberration of the "reflex cameras" is completely absent, and spherical distortions can be corrected by making the main mirror in the shape of a parabola. Such a mirror is called parabolic. The secondary mirror, which is also included in its design, is designed to deflect the rays of light reflected by the main mirror and display the image in the right direction.

It is the main mirror, which has the shape of a parabola, that has the unique property of clearly bringing all the light rays into one focus.

Mirror-lens telescopes

The optical design of mirror-lens telescopes includes both lenses and mirrors at the same time. The lens here is a spherical mirror, and the lenses are designed to eliminate all possible aberrations. If you compare mirror-lens telescopes with refractors and reflectors, you can immediately pay attention to the fact that catadioptrics have a short and compact tube. This is due to the system of multiple reflections of light rays. To use the colloquial language of amateur astronomers, the focus of such telescopes seems to be in a “folded state”. Due to the compactness and lightness of catadioptrics, they are very popular in the astronomical environment, but such telescopes are much more expensive than a simple refractor or the usual Newtonian “reflex camera”.

The principle of a telescope is not to magnify objects, but to collect light. The larger the size of the main light-collecting element - a lens or a mirror, the more light will enter it. It is important that it is the total amount of light collected that ultimately determines the level of detail visible - whether it be a distant landscape or the rings of Saturn. While the magnification, or power, of the telescope is also important, it is not critical to achieving the level of detail.

Telescopes are constantly changing and improving, but the principle of operation remains the same.

Telescope collects and concentrates light

The larger the convex lens or concave mirror, the more light enters it. And the more light enters, the more distant objects it allows you to see. The human eye has its own convex lens (crystalline lens), but this lens is very small, so it collects quite a bit of light. The telescope allows you to see more precisely because its mirror is able to collect more light than the human eye.

A telescope focuses light beams and creates an image

In order to create a clear image, the lenses and mirrors of the telescope collect the captured rays into one point - into focus. If the light is not collected at one point, the image will be blurry.

Types of telescopes

Telescopes can be divided according to the way they work with light into "lens", "mirror" and combined - mirror-lens telescopes.

Refractors are refractive telescopes. The light in such a telescope is collected using a biconvex lens (in fact, it is the lens of the telescope). Among amateur instruments, the most common achromats are usually two-lens, but there are also more complex ones. An achromatic refractor consists of two lenses - a converging and a diverging one, which allows you to compensate for spherical and chromatic aberrations - in other words, distortions in the flow of light when passing through the lens.

A bit of history:

Galileo's refractor (invented in 1609) used two lenses to collect as much starlight as possible. and let the human eye see it. Light passing through a spherical mirror forms an image. Galileo's spherical lens makes the picture fuzzy. In addition, such a lens decomposes light into color components, due to which a blurry colored area forms around the luminous object. Therefore, the spherical convex collects starlight, and the concave lens following it turns the collected light rays back into parallel ones, which allows you to restore clarity and clarity to the observed image.

Keppler refractor (1611)

Any spherical lens refracts light rays, defocuses them and blurs the picture. A spherical Keppler lens has less curvature and a longer focal length than a Galilean lens. Therefore, the focus points of rays passing through such a lens are closer to each other, which reduces, but does not completely eliminate, image distortion. In fact, Keppler himself did not create such a telescope, but the improvements he proposed had a strong influence on the further development of refractors.

Achromatic refractor

The achromatic refractor is based on the Keppler telescope, but instead of one spherical lens, it uses two lenses of different curvatures. Light passing through these two lenses is focused at one point, i.e. this method avoids both chromatic and spherical aberration.

- Telescope Sturman F70076

A simple and lightweight refractor for beginners with a 50mm objective lens. Magnification - 18*,27*,60*,90*. It is completed with two eyepieces - 6 mm and 20 mm. Can be used as a pipe as it does not flip the image. On the azimuth bracket. - >Telescope Konus KJ-7

60 mm long-focus refractor telescope on a German (equatorial) mount. The maximum magnification is 120x. Suitable for children and novice astronomers. - Telescope MEADE NGC 70/700mm AZ

A classic refractor with a diameter of 70 mm and a maximum useful magnification of up to 250*. Comes with three eyepieces, a prism and a mount. Allows you to observe almost all the planets of the solar system and faint stars up to magnitude 11.3. - Telescope Synta Skywatcher 607AZ2

A classic refractor on an azimuth mount AZ-2 on an aluminum tripod and the possibility of microdimensional pointing of the telescope in height. Objective diameter 60 mm, maximum magnification 120x, penetrating power 11 (magnitudes). Weight 5 kg. - Telescope Synta Skywatcher 1025AZ3

Lightweight refractor with AZ-3 alt-azimuth mount on an aluminum tripod with microdimensional telescope pointing on both axes. Can be used as a telephoto lens for most SLR cameras to capture distant subjects. Objective diameter 100 mm, focal length 500 mm, penetrating power 12 (magnitudes). Weight 14 kg.

Reflector is any telescope whose objective consists only of mirrors. Reflectors are reflecting telescopes, and the image in such telescopes is on the other side of the optical system than in refractors.

A bit of history

Gregory's reflecting telescope (1663)

James Gregory introduced a completely new technology to telescope construction by inventing the telescope with a parabolic primary mirror. The image that can be observed in such a telescope is free from both spherical and chromatic aberrations.

Newton's reflector (1668)

Newton used a metal primary mirror to collect the light and a follower mirror to direct the light rays towards the eyepiece. Thus, it was possible to cope with chromatic aberration - after all, mirrors are used in this telescope instead of lenses. But the picture still turned out blurry due to the spherical curvature of the mirror.

Until now, a telescope made according to Newton's scheme is often called a reflector. Unfortunately, it is not free from aberrations either. Slightly away from the axis, coma (non-isoplanatism) is already beginning to appear - an aberration associated with the uneven increase in different annular aperture zones. The coma causes the diffuse spot to look like a projection of a cone - the sharpest and brightest part towards the center of the field of view, obtuse and rounded away from the center. The size of the scattering spot is proportional to the distance from the center of the field of view and is proportional to the square of the aperture diameter. Therefore, the manifestation of coma is especially strong in the so-called "fast" (high-aperture) Newtons at the edge of the field of view.

Newtonian telescopes are very popular today: they are very simple and cheap to manufacture, which means that the average price level for them is much lower than for the corresponding refractors. But the design itself imposes some limitations on such a telescope: distortions of the rays passing through a diagonal mirror noticeably worsen the resolution of such a telescope, and with an increase in the diameter of the objective, the length of the tube increases proportionally. As a result, the telescope becomes too large, and the field of view with a long tube becomes smaller. Actually, reflectors with a diameter of more than 15 cm are practically not produced, because. The disadvantages of such devices will be more than advantages.

- Telescope Synta Skywatcher 1309EQ2

Reflector with a 130 mm objective lens on an equatorial mount. Max magnification 260. Insight 13.3 - Telescope F800203M STURMAN

Reflector with a 200 mm objective lens on an equatorial mount. Supplied with two eyepieces, moon filter, tripod and viewfinders. - Telescope Meade Newton 6 LXD-75 f/5 with EC Remote

A classic Newtonian reflector with a lens diameter of 150 mm and a useful magnification of up to 400x. A telescope for astronomy enthusiasts who appreciate a large light diameter and large aperture. An electronically driven mount with hourly tracking allows long exposure astrophotography.

Mirror lens(catadioptric) telescopes use both lenses and mirrors, whereby their optical design achieves excellent high-resolution image quality, while the entire structure consists of very short portable optical tubes.

Telescope parameters

Diameter and magnification

When choosing a telescope, it is important to be aware of objective lens diameter, resolution, magnification, and quality of construction and components.

The amount of light collected by a telescope directly depends on diameter(D) primary mirror or lens. The amount of light passing through the lens is proportional to its area.

In addition to the diameter, the characteristic of the lens is important value relative bore(A), equal to the ratio of the diameter to the focal length (it is also called aperture ratio).

Relative Focus called the reciprocal of the relative aperture.

Permission- is the ability to display details - ie. the higher the resolution, the better the image. A high-resolution telescope is able to separate two distant near objects, while a low-resolution telescope will only see one, mixed of the two, object. Stars are point sources of light, so they are difficult to observe, and only the diffraction image of a star can be seen in a telescope as a disk with a ring of light around it. Officially, the maximum resolution of a visual telescope is the minimum angular gap between a pair of stars of the same brightness, when they are still visible at sufficient magnification and the absence of interference from the atmosphere separately. This value for good instruments is approximately equal to 120/D arcseconds, where D is the telescope aperture (diameter) in mm.

Magnifications telescope should lie in the range from D / 7 to 1.5D, where D is the aperture diameter of the telescope objective. That is, for a tube with a diameter of 100 mm, eyepieces must be selected so that they provide magnifications from 15x to 150x.

With a magnification numerically equal to the diameter of the lens, expressed in millimeters, the first signs of a diffraction pattern appear, and further increase in magnification will only worsen the image quality, preventing fine details from being distinguished. In addition, it is worth remembering the jitter of the telescope, atmospheric turbulence, etc. Therefore, when observing the Moon and planets, magnifications exceeding 1.4D - 1.7D are usually not used. In any case, a good instrument should "pull out" up to 1.5D without significant deterioration in image quality. Refractors do this best, and reflectors with their central shielding can no longer work confidently at such magnifications, therefore, it is not advisable to use them for observing the Moon and planets.

The upper limit of rational magnifications is determined empirically and is related to the influence of diffraction phenomena (with increasing magnification, the size of the exit pupil of the telescope decreases - its exit aperture). It turned out that the highest resolution is achieved with exit pupils less than 0.7 mm, and further increase in magnification does not lead to an increase in the number of details. On the contrary, a loose, cloudy and dim image creates the illusion of reduced detail. Large magnifications of 1.5D make sense as more comfortable, especially for people with visual impairments and only for bright contrasting objects.

The lower limit of a reasonable range of magnifications is determined by the fact that the ratio of the lens diameter to the exit pupil diameter (i.e., the diameter of the light beam emerging from the eyepiece) is equal to the ratio of their focal lengths, i.e. increase. If the diameter of the beam exiting the eyepiece exceeds the diameter of the observer's pupil, some of the rays will be cut off, and the observer's eye will see less light - and a smaller part of the image.

Thus, the following series of recommended magnifications 2D, 1.4D, 1D, 0.7D, D/7 emerges. A magnification of D/2..D/3 is useful for observing ordinary-sized clusters and dim nebulous objects.

mounts

Telescope mount- the part of the telescope on which its optical tube is fixed. Allows you to direct it to the observed region of the sky, ensures the stability of its installation in the working position, the convenience of performing various types of observations. The mount consists of a base (or column), two mutually perpendicular axes for turning the telescope tube, a drive and a system for measuring the angles of rotation.

AT equatorial mount the first axis is directed to the celestial pole and is called the polar (or hourly) axis, and the second lies in the plane of the equator and is called the declination axis; a telescope tube is attached to it. When the telescope is rotated around the 1st axis, its hour angle changes at a constant declination; when rotated around the 2nd axis, the declination changes at a constant hour angle. If the telescope is mounted on such a mount, tracking of a celestial body moving due to the apparent diurnal rotation of the sky is carried out by rotating the telescope at a constant speed around one polar axis.

AT azimuthal mount the first axis is vertical, and the second, carrying the pipe, lies in the horizon plane. The first axis is used to rotate the telescope in azimuth, the second - in height (zenith distance). When observing stars with a telescope mounted on an azimuth mount, it must be rotated continuously and with a high degree of accuracy around two axes simultaneously, and at speeds that vary according to a complex law.

Used photos from www.amazing-space.stsci.edu

optical telescope- a tool for collecting and focusing electromagnetic radiation in the optical range. The telescope increases the brightness and apparent angular size of the observed object. Simply put, a telescope allows you to study finer details of the object of observation, by increasing the amount of incoming light. With a telescope, you can observe with the eye (visual observations), and you can also take photos or videos. To determine the characteristics of the telescope, the main parameters are the diameter (aperture) and focal length of the objective, as well as the focal length and field of view of the eyepiece. The telescope is mounted on a mount, which allows you to make the observation process more comfortable. The mount makes it possible to simplify the process of pointing and tracking the object of observation.

According to the optical scheme, telescopes are divided into:

Lens (refractors or diopters) - a lens or lens system is used as a lens.

- Mirror (reflectors or cataptric) - a concave mirror is used as a lens.

- Mirror-lens telescopes (catadioptric) - a spherical mirror is used as an objective, and a lens, lens system or meniscus serves to compensate for aberrations.

The first astronomer to build a telescope was the Italian Galileo Galilei. The created telescope was of modest size, the length of the tube was 1245 mm, the diameter of the objective was 53 mm, and the eyepiece was 25 diopters. Its optical design was not perfect, and the magnification was only 30x. But for all its shortcomings, having more than a modest size, the telescope made it possible to make a number of remarkable discoveries: craters and mountains on the Moon, four satellites of Jupiter, spots on the Sun, a change in the phases of Venus, strange “appendages” of Saturn (the ring of Saturn, which was subsequently discovered by and described by Huygens), the aurora in the Milky Way consists of stars.

Portrait of Galileo, a broken lens from the first telescope in the center of the vignette and his telescopes on a museum stand, stored in the Museum of the History of Science (Florence).

Classical optical schemes.

Galileo's scheme.

In 1609, the Italian Galileo Galilei built the first telescope. His objective was one converging lens, and the diverging lens served as the eyepiece, as a result of which the image was not inverted (Earthly). The main disadvantages of such an optical scheme are very strong chromatic aberration and a small field of view. Until now, such a scheme is still used in theatrical binoculars and home-made amateur telescopes.

Kepler's scheme

In 1611, the German astronomer Johannes Kepler improved Galileo's telescope. He replaced the diverging lens in the eyepiece with a converging one. His changes made it possible to increase the field of view and eye relief. Such an optical scheme gives an inverted real image. In fact, all subsequent refracting telescopes are Kepler tubes. The disadvantages of the system include strong chromatic aberration, which, before the creation of an achromatic lens, was eliminated by reducing the relative aperture of the telescope.

Newton's scheme

In 1667, the English astronomer Isaac Newton proposed a scheme in which light falls on the main mirror, and then a flat diagonal mirror located near the focus deflects the beam of light outside the tube. The main mirror has a parabolic shape, and in the case when the relative aperture is not too large, the shape of the mirror is spherical.

Gregory's scheme

In 1663, the Scottish astronomer James Gregory proposed the following scheme in his book Optica Promota. The concave parabolic primary mirror reflects light onto the concave elliptical secondary mirror, after which the light, passing through the hole in the primary mirror, enters the eyepiece. The distance between the mirrors is greater than the focal length of the main mirror, so the image is upright (as opposed to inverted in a Newtonian telescope). The secondary mirror provides a relatively high magnification due to the lengthening of the focal length.

Cassegrain scheme

In 1672, the Frenchman Laurent Cassegrain proposed a scheme for a two-mirror telescope lens. The concave primary mirror (originally parabolic) reflects light onto a smaller, convex, hyperbolic secondary mirror, which then enters the eyepiece. According to Maksutov's classification, the scheme belongs to the so-called pre-focal lengthening - that is, the secondary mirror is located between the main mirror and its focus and the total focal length of the lens is greater than that of the main one. The lens with the same diameter and focal length has almost half the tube length and slightly less shielding than Gregory's. The system is not aplanatic, that is, not free from coma aberration. It has many mirror modifications, including the aplanatic Ritchie-Chrétien, with a spherical surface of the secondary (Doll-Kirkham) or primary mirror, and mirror-lens.

Maksutov-Cassegrain scheme

In 1941, the Soviet scientist, optician D. D. Maksutov found that the spherical aberration of a spherical mirror can be compensated for by a meniscus of large curvature. Having found a good distance between the meniscus and the mirror, Maksutov managed to get rid of coma and astigmatism. The curvature of the field, as in the Schmidt camera, can be eliminated by installing a plano-convex lens near the focal plane - the so-called Piazzi-Smith lens. By modifying the Cassegrain system, Maksutov created one of the most common systems in astronomy.

Ritchey-Chrétien scheme

In the early 1910s, the American and French astronomers George Ritchie and Henri Chrétien invented the optical design of the refractor telescope, a variation of the Cassegrain system. A feature of the Ritchie-Chrétien system, which distinguishes it from most other variants of the Cassegrain system, is the absence of third-order coma and spherical aberration. On the other hand, high-angle astigmatism and field curvature are great; the latter, however, is corrected by a simple two-lens field corrector. Like other cassegrains, it has a short body, a secondary mirror, which in the case of the Ritchey-Chrétien system is hyperbolic and prevents the appearance of coma and contributes to a wide field. This scheme is the most common in scientific telescopes. The most famous telescope using the Ritchie-Chrétien scheme is the Hubble Space Telescope.

Since the creation of the first telescope in 1611, astronomers have made discoveries by observing visually. As science progressed so did the methods of observation. After 1920, photographic plates became the receiver of the image. Although the eye is the most complex organ, in terms of sensitivity it is significantly inferior to photographic plates.

The next breakthrough was the creation of the CCD after 1980. In terms of sensitivity, they were significantly superior to photographic plates, and were much more convenient to use. In all modern telescopes, image sensors are CCD arrays. CCD matrix or CCD-matrix is a specialized analog integrated circuit, consisting of light-sensitive photodiodes, made on the basis of silicon, using CCD technology - charge-coupled devices. The resulting images are processed digitally on a computer. To obtain clear images without digital noise, the matrix is cooled to -130°C.

The largest telescope in Russia is BTA ("Large Azimuth Telescope").

The main mirror (MZ) has the shape of a paraboloid of revolution and a focal length of 24 m. The diameter of the mirror is 605 cm. The mass of the main mirror is 42 tons. The mass of the telescope is 850 tons. The height of the telescope is 42 m. The height of the tower is 53 m. The diameter of the primary focus cabin is 2 m. There are interchangeable optical instruments, as well as a drive mechanism for moving the lens corrector and the hyperbolic secondary mirror. Laboratory tests show that 90% of the energy is concentrated in a circle with a diameter of 0.8". The image diameter is determined by the microclimate in the tower room, as well as the temperature of the mirror. image is limited by atmospheric turbulence.The optical scheme of the BTA provides observations in the primary focus (aperture f/4) and in two Nasmith foci (aperture f/30).The restructuring time of the optical scheme is about 3-4 minutes, which makes nights of observations using equipment installed at different foci of the telescope.

At the moment, the largest telescope built is Very Large Telescope VLT (very large telescope).

The telescope complex was built by the European Southern Observatory (ESO). This is a complex of four separate 8.2-meter and four auxiliary 1.8-meter optical telescopes, combined into one system. The complex is located in the Republic of Chile on Mount Cerro Paranal, 2635 meters above sea level. The main 8.2 meter telescopes are housed in compact temperature-controlled towers that rotate in sync with the telescopes themselves. Such a scheme minimizes any distorting effects of external conditions during observations, for example, optical distortions introduced by air turbulence in the telescope tube, which usually appear due to changes in temperature and wind. The first of the Main Telescopes, Antu, began regular scientific observations on April 1, 1999. All four Main and all four Auxiliary Telescopes are currently in operation. VLT Main Telescope Towers: height 2850 cm, diameter 2900 cm. Although four 8.2 meter Main Telescopes can be used in combination to form the VLTI, they are primarily used for individual observations; in the interferometric mode, they operate only a limited number of nights per year. But thanks to four smaller dedicated Auxiliary Telescopes (ATs), the VLTI can function every night.

The Very Large Telescope is equipped with a large arsenal of imagers, allowing it to observe wavelengths ranging from near ultraviolet to mid-infrared. The adaptive optics system installed on the telescope almost completely eliminates the influence of the turbulent atmosphere in the infrared range. The resulting images in this range are sharper than those obtained by the Hubble telescope.

It's safe to say that everyone has ever dreamed of taking a closer look at the stars. With binoculars or a spyglass, you can admire the bright night sky, but you are unlikely to be able to see anything in detail with these devices. Here you need more serious equipment - a telescope. To have such a miracle of optical technology at home, you need to pay a large amount, which not all lovers of beauty can afford. But do not despair. You can make a telescope with your own hands, and for this, no matter how absurd it may sound, it is not necessary to be a great astronomer and designer. If only there was a desire and an irresistible craving for the unknown.

Why should you try making a telescope? We can definitely say that astronomy is a very complex science. And it requires a lot of effort from the person involved in it. It may happen that you get an expensive telescope, and the science of the Universe will disappoint you, or you simply realize that this is absolutely not your job. In order to figure out what's what, it's enough to make a telescope for an amateur. Observing the sky through such an apparatus will allow you to see many times more than through binoculars, and you can also figure out if this activity is interesting for you. If you get excited about studying the night sky, then, of course, you cannot do without a professional apparatus. What can you see with a homemade telescope? Descriptions of how to make a telescope can be found in many textbooks and books. Such a device will allow you to clearly see the lunar craters. With it, you can see Jupiter and even see its four main satellites. The rings of Saturn familiar to us from the pages of textbooks can also be seen with a telescope made by ourselves.

In addition, many more celestial bodies can be seen with your own eyes, for example, Venus, a large number of stars, clusters, nebulae. A little about the structure of the telescope The main parts of our unit are its lens and eyepiece. With the help of the first detail, the light emitted by celestial bodies is collected. How far away bodies can be seen, as well as what the magnification of the device will be, depends on the diameter of the lens. The second member of the tandem, the eyepiece, is designed to increase the resulting image so that our eye can admire the beauty of the stars. Now about the two most common types of optical devices - refractors and reflectors. The first type has a lens made of a lens system, and the second has a mirror lens. Lenses for a telescope, unlike a reflector mirror, can be easily found in specialized stores. Buying a mirror for a reflector will cost a lot, and making it yourself will be impossible for many.

Therefore, as it has already become clear, we will assemble a refractor, and not a mirror telescope. Let's finish the theoretical digression with the concept of telescope magnification. It is equal to the ratio of the focal lengths of the lens and the eyepiece. Personal experience: how I did laser vision correction Actually, I did not always radiate joy and self-confidence. But first things first .. How to make a telescope? We select materials In order to start assembling the device, you need to stock up on a 1-diopter lens or its blank. By the way, such a lens will have a focal length of one meter. The diameter of the blanks will be about seventy millimeters. It should also be noted that it is better not to choose lenses for a telescope, as they are mostly concave-convex in shape and are not suitable for a telescope, although if they are at hand, then you can use them. It is recommended to use long focal length biconvex lenses. As an eyepiece, you can take an ordinary magnifying glass of a thirty-millimeter diameter. If it is possible to get an eyepiece from a microscope, then, undoubtedly, it is worth using it. It's great for a telescope too. What to make a case for our future optical assistant? Two pipes of different diameters made of cardboard or thick paper are perfect. One (the one that is shorter) will be inserted into the second, with a larger diameter and longer.

A pipe with a smaller diameter should be made twenty centimeters long - this will eventually be an ocular node, and it is recommended to make the main one meter long. If you don’t have the necessary blanks at hand, it doesn’t matter, the case can be made from an unnecessary roll of wallpaper. To do this, the wallpaper is wound in several layers to create the desired thickness and rigidity and glued. How to make the diameter of the inner tube depends on which lens we use. Stand for a telescope A very important point in creating your own telescope is the preparation of a special stand for it. Without it, it will be almost impossible to use it. There is an option to install the telescope on a tripod from the camera, which is equipped with a moving head, as well as fasteners that will allow you to fix various positions of the body. Assembling the telescope The objective lens is fixed in a small tube with the bulge outward. It is recommended to fix it with the help of a frame, which is a ring similar in diameter to the lens itself.

You have a wonderful blank for the main mirror. But only if it's K8 lenses. Because in condensers (and these are undoubtedly condenser lenses) they often put a pair of lenses, one of which is from a crown, the other from a flint. A flint lens as a blank for the main mirror is absolutely unsuitable for a number of reasons (one of which is its high sensitivity to temperature). A flint lens is great as a base for a polishing pad, but it will not work with it, since the flint has a much greater hardness and abradability than a crown. In this case, use a plastic grinder.

Secondly, I strongly advise you to carefully read not only the book by Sikoruk, but also the "Telescope of an amateur astronomer" by M.S. Navashina. And as far as tests and measurements of the mirror are concerned, one should be guided precisely by Navashin, in whom this aspect is described in great detail. Naturally, it is not worth making a shadow device "according to Navashin" exactly, since now it is easy to introduce such improvements into its design as using a powerful LED as a light source (which will significantly increase the light intensity and the quality of measurements on an uncoated mirror, and also allow bring the "star" close to the knife; it is advisable to use a rail from an optical bench as a base, etc.). The manufacture of a shadow device must be approached with all the attention, since it is how well you make it that will determine the quality of your mirror.

In addition to the aforementioned rail from the optical bench, a useful “swag” for its manufacture is a support from a lathe, which will be a wonderful device for smoothly moving the Foucault knife and at the same time measuring this movement. An equally useful find would be a ready-made slit from a monochromator or diffractometer. I also advise you to adapt a webcam to the shadow device - this will eliminate the error from the position of the eye, reduce convection interference from the heat of your body, and in addition, it will allow you to register and store all shadow pictures during the process of polishing and figuring the mirror. In any case, the base for the shadow device must be reliable and heavy, the fastening of all parts must be ideally rigid and durable, and the movement must be without backlash. Organize a pipe or tunnel along the entire path of the rays - this will reduce the effect of convection currents, and in addition, it will allow you to work in the light. In general, convection currents are the scourge of any mirror testing methods. Fight them with all possible means.

Invest in good quality abrasives and resins. Cooking resin and elutriating abrasives is, firstly, an unproductive expenditure of energy, and secondly, bad resin is a bad mirror, and bad abrasives are a bunch of scratches. But the grinding machine can and should be the most primitive, the only requirement for it is the impeccable rigidity of the structure. Here, a wooden barrel covered with rubble is absolutely ideal, around which Chikin, Maksutov and other "founding fathers" used to walk around. A useful addition to Chikin's barrel is the "Grace" disk, which allows you not to wind kilometers around the barrel, but to work while standing in one place. A barrel for peeling and rough grinding is better to equip on the street, but fine grinding and polishing is a matter for a room with a constant temperature and without drafts. An alternative to a barrel, especially at the stage of fine grinding and polishing, is the floor. Of course, it is less convenient to work on your knees, but the rigidity of such a "machine" is ideal.

Particular attention must be paid to fixing the workpiece. A good option for unloading the lens is gluing a "patch" of minimum size in the center and three stops near the edges, which should only touch, but not put pressure on the workpiece. Piglet needs to be ground on a plane and brought to No. 120.

To prevent scratches and chips, it is necessary to make a chamfer along the edge of the workpiece before peeling and bring it to fine grinding. The width of the chamfer should be calculated so that it remains until the end of the work with the mirror. If the chamfer "ends" in the process, it must be resumed. The chamfer must be uniform, otherwise it will be a source of astigmatism.

The most rational is peeling with a ring, or with a reduced grinder in the “mirror from below” position, but given the small size of the mirror, you can also do it according to Navashin - a mirror from above, a grinder of normal size. Silicon carbide or boron carbide is used as an abrasive. When peeling, one must beware of picking up astigmatism and "going away" into a hyperboloid form, to which such a system has a clear tendency. The alternation of a normal stroke with a shortened one helps to avoid the latter, especially towards the end of the peeling. If, during roughing, a surface that is as close to a sphere as possible is initially obtained, this will dramatically speed up all further work on grinding.

Abrasives when grinding - starting from the 120th number and smaller, it is better to use electrocorundum, and larger - carborundum. The main characteristic of abrasives to strive for is the narrowness of the particle distribution spectrum. If the particles in a given number of abrasive vary in size, then larger grains are the source of scratches, and smaller grains are the source of local errors. And with abrasives of this quality, their "ladder" should be much flatter, and we will come to polishing with "waves" on the surface, which we will then get rid of for a long time.

A shamanic trick against this with not the best abrasives is to grind the mirror with an even finer abrasive before changing the number to a thinner one. For example, instead of the series 80-120-220-400-600-30u-12u-5u, the series will be: 80-120-400-220-600-400-30u-600... and so on, and these intermediate steps short. Why it works, I don't know. With a good abrasive, you can grind after the 220th number immediately with thirty microns. It is good to add Fairy abrasives to coarse (up to No. 220) abrasives diluted with water. It makes sense to look for micron powders with the addition of talc (or add it yourself, but you need to be sure that talc is abrasive-sterile) - it reduces the likelihood of scratches, facilitates the grinding process and reduces biting.

Another tip that allows you to control the shape of the mirror even at the stage of grinding (not even fine) is to polish the surface by grinding it with suede with polyrite to a shine, after which you can easily determine the focal length by the Sun or a lamp and even (at finer stages of grinding) get shadow picture. A sign of the accuracy of the spherical shape is also the uniformity of the ground surface and the rapid uniform grinding of the entire surface after changing the abrasive. Vary the length of the stroke within small limits - this will help to avoid a "broken" surface.

The process of polishing and figuring is probably described so well and in detail that it is more reasonable not to go into it, but to refer it to Navashin. True, he recommends crocus, but now everyone uses polyrite, otherwise everything is the same. Crocus, by the way, is useful for figuring - it works more slowly than polyrite, and there is less risk of "missing" the desired shape.

Directly behind the lens, further along the pipe, it is necessary to equip the diaphragm in the form of a disk with a thirty-millimeter hole strictly in the middle. Aperture is designed to negate the distortion of the picture that appears in connection with the use of a single lens. Also, setting it will affect the reduction of light that the lens receives. The telescope lens itself is mounted near the main tube. Naturally, in the ocular assembly one cannot do without the eyepiece itself. First you need to prepare fasteners for it. They are made in the form of a cardboard cylinder and are similar to the eyepiece in diameter. Fastening is established in a pipe by means of two disks. They are the same diameter as the cylinder and have holes in the middle. Setting up the device at home It is necessary to focus the image using the distance from the lens to the eyepiece. To do this, the ocular assembly moves in the main tube.

Since the pipes must be well pressed together, the required position will be securely fixed. The tuning process is convenient to carry out on large bright bodies, for example, the Moon, and a neighboring house will also do. When assembling, it is very important to ensure that the lens and the eyepiece are parallel and their centers are on the same straight line. Another way to make a telescope with your own hands is to change the aperture size. By varying its diameter, you can achieve the optimal picture. Using optical lenses of 0.6 diopters, which have a focal length of about two meters, it is possible to increase the aperture and make the zoom on our telescope much larger, but it should be understood that the body will also increase.

Beware of the Sun! By the standards of the Universe, our Sun is far from the brightest star. However, for us it is a very important source of life. Naturally, having a telescope at their disposal, many will want to take a closer look at it. But you need to know that it is very dangerous. After all, sunlight, passing through the optical systems we have built, can be focused to such an extent that it will be able to burn through even thick paper. What can we say about the delicate retina of our eyes. Therefore, one must remember a very important rule: one should not look at the Sun through zooming devices, especially through a home telescope, without special protective equipment.

First of all, you need to purchase a lens and an eyepiece. As a lens, you can use two glasses for glasses (menisci) of +0.5 diopters, placing them with their convex sides one outward and the other inward at a distance of 30 mm from one another. Between them, put a diaphragm with a hole with a diameter of about 30 mm. This is the last resort. But it is better to use a long-focal biconvex lens.

For an eyepiece, you can take an ordinary magnifying glass (loupe) 5-10 times with a small diameter of about 30 mm. As an option, there may also be an eyepiece from a microscope. Such a telescope will give a magnification of 20-40 times.

For the case, you can take thick paper or pick up metal or plastic tubes (there should be two of them). A short tube (about 20 cm, ocular assembly) is inserted into a long one (about 1m, main). The inner diameter of the main tube should be equal to the diameter of the spectacle lens.

The lens (spectacle lens) is mounted in the first tube with the convex side outward using a frame (rings with a diameter equal to the diameter of the lens and a thickness of about 10 mm). Immediately behind the lens, a disk is installed - a diaphragm with a hole in the center with a diameter of 25 - 30 mm, this is necessary in order to reduce significant image distortions obtained by a single lens. The lens is mounted closer to the edge of the main pipe. The eyepiece is installed in the eyepiece node closer to its edge. To do this, you will have to make a mount for the eyepiece out of cardboard. It will consist of a cylinder, equal in diameter to the eyepiece. This cylinder will be attached to the inside of the tube with two discs with a diameter equal to the inner diameter of the eyepiece assembly with a hole equal in diameter to the eyepiece.

Focusing is done by changing the distance between the lens and the eyepiece due to the movement of the eyepiece unit in the main tube, and fixation will occur due to friction. Focusing is best done on bright and large objects: the moon, bright stars, nearby buildings.

When creating a telescope, it is necessary to take into account that the lens and the eyepiece must be parallel to each other, and their centers must be strictly on the same line.

Making a homemade reflecting telescope

There are several systems of reflecting telescopes. It is easier for an amateur astronomer to make a Newtonian reflector.

Plano-convex condenser lenses for photographic enlargers can be used as mirrors by processing their flat surface. Such lenses with a diameter of up to 113 mm can also be purchased at photo stores.

The concave spherical surface of a polished mirror reflects only about 5% of the light falling on it. Therefore, it must be covered with a reflective layer of aluminum or silver. It is impossible to aluminize a mirror at home, but it is quite possible to silver it.

In a Newtonian reflecting telescope, a diagonal flat mirror deflects sideways the cone of rays reflected from the main mirror. It is very difficult to make a flat mirror yourself, so use a prism with total internal reflection from prism binoculars. You can also use a flat lens surface for this purpose, the surface of a light filter from a camera. Cover it with silver.

Eyepiece set: weak eyepiece with a focal length of 25-30 mm; average 10-15 mm; strong 5-7 mm. You can use eyepieces from a microscope, binoculars, lenses from small-format movie cameras for this purpose.

Mount the main mirror, flat diagonal mirror and eyepiece in the telescope tube.

For a reflecting telescope, make a parallax tripod with a polar axis and a declination axis. The polar axis should be directed to the North Star.

Such means are light filters and a method of projecting an image onto a screen. What if you didn’t manage to assemble a telescope with your own hands, but you really want to look at the stars? If suddenly, for some reason, assembling a homemade telescope is impossible, then do not despair. You can find a telescope in the store for a reasonable price. The question immediately arises: "Where are they sold?" Such equipment can be found in specialized stores of astro-devices. If there is no such thing in your city, then you should visit a photographic equipment store or find another store selling telescopes. If you are lucky - in your city there is a specialized store, and even with professional consultants, then you are definitely there. It is recommended to look at the review of telescopes before the trip. First, you will understand the characteristics of optical devices. Secondly, it will be more difficult for you to deceive and slip low-quality goods.

Then you will definitely not be disappointed in the purchase. A few words about buying a telescope through the World Wide Web. This type of shopping is becoming very popular in our time, and it is possible that you will use it. It is very convenient: you look for the device you need, and then order it. However, you can stumble upon such a nuisance: after a long selection, it may turn out that the product is no longer available. A much more unpleasant problem is the delivery of goods. It's no secret that the telescope is a very fragile thing, so only fragments can be brought to you. It is possible to buy a telescope with hands.

This option will allow you to save a lot, but you should be well prepared so as not to buy a broken item. A good place to find a potential seller is the astronomy forums. Price for a telescope Consider some price categories: About five thousand rubles. Such a device will correspond to the characteristics that a do-it-yourself telescope has at home. Up to ten thousand rubles. This device will certainly be more suitable for high-quality observation of the night sky. The mechanical part of the case and the equipment will be very scarce, and you may have to spend money on some spare parts: eyepieces, filters, etc. From twenty to one hundred thousand rubles. This category includes professional and semi-professional telescopes.

Amateur astronomers build homemade reflecting telescopes mainly according to Newton's system. It was Isaac Newton who invented the first reflecting telescope around 1670. This allowed him to get rid of chromatic aberrations (they lead to a decrease in the clarity of the image, to the appearance of colored contours or stripes on it, which are not present on a real object) - the main drawback of the refracting telescopes that existed at that time.

diagonal mirror - this mirror directs the beam of reflected rays through the eyepiece to the observer. The element marked with the number 3 is the ocular assembly.

The focus of the main mirror and the focus of the eyepiece inserted into the eyepiece tube must match. The focus of the primary mirror is defined as the apex of the cone of rays reflected by the mirror.

The diagonal mirror is made in small sizes, it is flat and can have a rectangular or elliptical shape. A diagonal mirror is mounted on the optical axis of the main mirror (objective), at an angle of 45° to it.

An ordinary household flat mirror is not always suitable for use as a diagonal mirror in a homemade telescope - an optically more accurate surface is needed for a telescope. Therefore, a flat surface of a plano-concave or plano-convex optical lens can be used as a diagonal mirror if this plane is first coated with a layer of silver or aluminum.

The dimensions of a flat diagonal mirror for a homemade telescope are determined from the graphical construction of the cone of rays that are reflected by the main mirror. With a rectangular or elliptical mirror, the sides or axes are related to each other as 1:1.4.

The objective and eyepiece of a self-made reflecting telescope are mounted mutually perpendicular in the telescope tube. To mount the main mirror of a homemade telescope, a frame, wooden or metal, is required.

To make a wooden frame for the main mirror of a home-made reflecting telescope, you can take a round or octagonal plate at least 10 mm thick and 15-20 mm larger than the diameter of the main mirror. The main mirror is fixed on this plate with 4 pieces of a thick-walled rubber tube, put on screws. For better fixation, plastic washers can be placed under the screw heads (the mirror itself cannot be clamped with them).

The pipe of a homemade telescope is made from a piece of metal pipe, from several layers of cardboard glued together. You can also make a metal-cardboard pipe.

Three layers of thick cardboard should be glued together with carpentry or casein glue, then insert the cardboard tube into the metal stiffening rings. They also make a bowl for the frame of the main mirror of a homemade telescope and a pipe cover from metal.

The length of the tube (tube) of a home-made reflecting telescope should be equal to the focal length of the main mirror, and the inner diameter of the tube should be 1.25 of the diameter of the main mirror. From the inside, the tube of a home-made reflecting telescope should be “blackened”, i.e. cover with matte black paper or paint with matte black paint.

The ocular assembly of a homemade reflecting telescope in the simplest version can be based, as they say, “on friction”: the movable inner tube moves along the stationary outer tube, providing the necessary focusing. The ocular assembly can also be threaded.

Before use, a home-made reflecting telescope must be installed on a special stand - a mount. You can purchase both a ready-made factory mount, and make it yourself, from improvised materials. You can read more about the types of mounts for homemade telescopes in our next materials.

Surely a beginner will not need a mirror device with an astronomical cost. It is simply, as they say, a waste of money. Conclusion In the end, we got acquainted with important information on how to make a simple telescope with your own hands, and some of the nuances of buying a new apparatus for observing stars. In addition to the method that we examined, there are others, but this is a topic for another article. Whether you have built a telescope at home or purchased a new one, astronomy will allow you to immerse yourself in an unknown world and get experiences that you have never experienced before.

A spectacle tube is essentially a simple refractor with a single lens instead of a lens. The rays of light coming from the observed object are collected in the tube by a lens objective. To destroy the iridescent coloring of the image - chromatic aberration - use two lenses from different types of glass. Each surface of these lenses must have its own curvature, and

all four surfaces must be coaxial. It is almost impossible to make such a lens in amateur conditions. It is difficult to get a good, even a small, lens objective for a telescope.

H0 is another system - a reflecting telescope. or reflector. In it, the lens is a concave mirror, where the exact curvature needs to be given to only one reflective surface. How is it arranged?

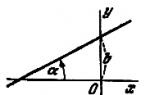

Rays of light come from the observed object (Fig. 1). The main concave (in the simplest case, spherical) mirror 1, which collects these rays, gives an image in the focal plane, which is viewed through the eyepiece 3. In the path of the beam of rays reflected from the main mirror, a small flat mirror 2 is placed, located at an angle of 45 degrees to optical axis of the main. It deflects the cone of rays at a right angle so that the observer does not obstruct the open end of the telescope tube 4 with his head. On the side of the tube opposite the diagonal flat mirror, a hole was cut for the exit of the cone of rays and the eyepiece tube 5 was fixed. that the reflective surface is processed with very high accuracy - the deviation from the specified size should not exceed 0.07 microns (seven hundred-thousandths of a millimeter), - the manufacture of such a mirror is quite affordable for a schoolboy.

First, cut out the main mirror.

The main concave mirror can be made from ordinary mirror, table or display glass. It should have sufficient thickness and be well annealed. Poorly annealed glass warps strongly when the temperature changes, and this distorts the shape of the mirror surface. Plexiglas, plexiglass and other plastics are not suitable at all. The thickness of the mirror should be slightly more than 8 mm, the diameter should not exceed 100 mm. Under a piece of a metal pipe of a suitable diameter with a wall thickness of 02-2 mm, a slurry of emery powder or carborundum powder with water is applied. Two disks are cut out of mirror glass. Manually from glass with a thickness of 8 - 10 mm, you can cut a disk with a diameter of 100 mm in about an hour to facilitate work, you can use a machine tool (Fig. 2).

Frame reinforced on base 1

3. An axis 4 passes through the middle of its upper crossbar, equipped with a handle 5. A tubular drill 2 is fixed at the lower end of the axis, and a load b is at the upper end. The axis of the drill can be equipped with bearings. You can make a motor drive, then you do not have to turn the handle. The machine is made of wood or metal.

Now - polishing

If you put one glass disk on top of another and, having smeared the contacting surfaces with a gruel of abrasive powder with water, move the upper disk towards you and away from you, at the same time uniformly rotating both disks in opposite directions, then they will be ground to each other. The lower disc gradually becomes more and more convex, and the upper disc becomes concave. When the desired radius of curvature is reached - which is checked by the depth of the center of the recess - the arrow of curvature - they move on to finer abrasive powders (until the glass becomes dark matte). The radius of curvature is determined by the formula: X =

where y is the radius of the primary mirror; . R is the focal length.

for the first homemade telescope, the mirror diameter (2y) is chosen to be 100-120 mm; F - 1000--1200 mm. The concave surface of the upper disk will be reflective. But it still needs to be polished and coated with a reflective layer.

How to get an accurate sphere

The next step is polishing.

The instrument is still the same second glass disc. It needs to be turned into a polishing pad, and for this, a layer of resin with an admixture of rosin is applied to the surface (the mixture gives the polishing layer greater hardness).

Cook the resin for the polisher like this. Rosin is melted in a small saucepan over low heat. and then small pieces of soft resin are added to it. The mixture is stirred with a stick. It is difficult to determine the ratio of rosin and resin in advance. Having cooled a drop of the mixture well, you need to test it for hardness. If the thumbnail leaves a shallow mark with strong pressure, the hardness of the resin is close to the required one. it is impossible to bring the resin to a boil and the formation of bubbles; it will be unsuitable for work. A network of longitudinal and transverse grooves is cut on the layer of the polishing mixture so that the polishing agent and air circulate freely during work and the resin patches make good contact with the Mirror. Polishing is done in the same way as grinding: the mirror moves back and forth; in addition, both the polisher and the mirror are turned little by little in opposite directions. In order to obtain the most accurate sphere possible, during grinding and polishing it is very important to observe a certain rhythm of movements, uniformity in the length of the “stroke” and the turns of both glasses.

All this work is done on a simple home-made machine (Fig. 3), similar in design to a pottery one. On the basis of a thick board is placed a rotating wooden table with an axis passing through the base. A grinder or polisher is fixed on this table. So that the tree does not warp, it is impregnated with oil, paraffin or waterproof paint.

Fouquet comes to the rescue

Is it possible, without resorting to a special optical laboratory, to check how accurate the surface of the mirror turned out to be? You can, if you use a device designed about a hundred years ago by the famous French physicist Foucault. The principle of its operation is surprisingly simple, and the measurement accuracy is up to hundredths of a micrometer. The famous Soviet optician D. D. Maksutov in his youth made an excellent parabolic mirror (and it is much more difficult to obtain a parabolic surface than a sphere), using this device assembled from a kerosene lamp, a piece of cloth from a hacksaw saw and wooden blocks to test it . Here is how it works (Figure 4)

A point light source I, for example, a puncture in a foil illuminated by a bright bulb, is located near the center of curvature O of mirror Z. The mirror is slightly rotated so that the top of the cone of reflected rays O1 is located somewhat away from the light source itself. This vertex can be crossed by a thin flat screen H with a straight edge - the "Foucault knife". By placing the eye behind the screen near the point where the reflected rays converge, we will see that the entire mirror is, as it were, flooded with light. If the surface of the mirror is exactly spherical, then when the screen crosses the top of the cone, the entire mirror will begin to fade evenly. And a spherical surface (not a sphere) cannot - can collect all the rays at one point. Some of them will intersect in front of the screen, some - behind it. Then we see a relief shadow pattern” (Fig. 5), which can be used to find out what deviations from the sphere are on the surface of the mirror. By changing the polishing mode in a certain way, they can be eliminated.

The sensitivity of the shadow method can be judged from such experience. If you put your finger on the surface of the mirror for a few seconds and then look using a shadow device; then at the place where the finger was attached, a hillock will be visible with a rather

a noticeable shadow, gradually disappearing. The shadow device clearly showed the slightest elevation formed from the heating of a section of the mirror when it came into contact with a finger. If “Foucault's knife extinguishes the entire mirror at the same time, then its surface is indeed an exact sphere.

Some more important tips

When the mirror has been polished and its surface has been finely shaped, the reflective concave surface must be aluminized or silver plated. The reflective aluminum layer is very durable, but it is possible to cover the mirror with it only on a special installation under vacuum. Alas, fans of such installations do not have. But you can silver the mirror at home. The only pity is that the silver fades rather quickly and the reflective layer has to be renewed.

A good main mirror for a telescope is the main one. A flat diagonal mirror in small reflecting telescopes can be replaced by a prism with total internal reflection, used, for example, in prismatic binoculars. Ordinary flat mirrors used in everyday life are not suitable for a telescope.

Eyepieces can be picked up from an old microscope or surveying instruments. In extreme cases, a single biconvex or plano-convex lens can also serve as an eyepiece.

The tube (tube) and the entire installation of the telescope can be made in a variety of ways - from the simplest, where the material is cardboard, planks and wooden blocks (Fig. 6), to very perfect ones. with Details and specially cast turned on a lathe. But the main thing is the strength, stability of the pipe. Otherwise, especially at high magnifications, the image will tremble and it will be difficult to focus the eyepiece, and it is inconvenient to work with the telescope

Now the key is patience.

A schoolboy in the 7th or 8th grade can make a telescope that gives very good images at magnifications up to 150 times or more. But this work requires a lot of patience, perseverance and accuracy. But what joy and pride should one feel who gets acquainted with the cosmos with the help of the most accurate optical device - a telescope made by one's own hands!

The heaviest part for independent production is the main mirror. We recommend you a new rather simple method of its manufacture, for which there is no need for complex equipment and special machines. True, you need to strictly follow all the advice in fine grinding and especially mirror polishing. Only under this condition can you build a telescope that is in no way worse than an industrial one. It is this detail that causes the most difficulties. Therefore, we will talk about all the other details very briefly.

The blank for the main mirror is a glass disk 15-20 mm thick.

You can use a lens from a photographic enlarger condenser, which is often sold in photographic shopping centers. Or glue with epoxy glue from thin glass discs that are easy to cut with a diamond or roller glass cutter. Take care to keep the adhesive joint as thin as possible. A "layered" mirror has some advantages over a solid one - it is not so prone to warping with changes in ambient temperature, and consequently, it gives a better image quality.

The grinding disc can be glass, iron or cement-concrete. The diameter of the grinding wheel should be equal to the diameter of the mirror, and its thickness should be 25-30mm. The working surface of the grinder should be glass or, even better, made of cured epoxy resin with a layer of 5-8mm. Therefore, if you managed to carve or select a suitable disk on scrap metal, or cast it from a cement mortar (1 part of cement and 3 shares of sand), then you need to arrange its working side, as shown in Figure 2.

Abrasive grinding powders can be made from carborundum, corundum, emery or quartz sand. The latter polishes slowly, but despite all the above, the quality of the finish is noticeably higher. Abrasive grains (200-300 g will be needed) for rough grinding, when we need to make the desired radius of curvature in the mirror blank, should be 0.3-0.4 mm in size. In addition, smaller powders with grain sizes will be required.

If it is not possible to purchase ready-made powders, then it is quite possible to prepare them yourself by crushing small pieces of a grinding abrasive wheel in a mortar.

Rough polished mirror.

Fix the grinder on a stable cabinet or table with the working side up. You have to worry about the painstaking cleaning of your home sander "machine" after changing the abrasives. Why on its surface it is necessary to lay a layer of linoleum or rubber. A special pallet is very convenient, which, together with the mirror, can then be removed from the table after work. Rough grinding is done by a reliable "old-fashioned" method. Mix the abrasive with water in a ratio of 1:2. Smear on the surface of the grinder about 0.5 cm3. the resulting slurry, put the mirror blank with the outer side down and start grinding. Hold the mirror with 2 hands, this will prevent it from falling, and the correct position of the hands will quickly and accurately obtain the desired radius of curvature. Make movements during grinding (strokes) in the direction of the diameter, evenly turning the mirror and grinder.

Try from the very beginning to accustom yourself to the subsequent rhythm of work: for every 5 strokes, 1 turn the mirror in your hands by 60 °. Rate of work: approximately 100 strokes per minute. As you move the mirror back and forth over the surface of the grinder, try to keep it in a state of stable equilibrium on the circle line of the grinder. As the grinding progresses, the crunch of the abrasive and the intensity of grinding decrease, the plane of the mirror and the grinder become contaminated with spent abrasive and glass particles with water - sludge. It must be washed off or wiped with a damp sponge from time to time. After sanding for 30 minutes, check the indentation with a metal ruler and safety razor blades. Knowing the thickness and the number of blades that pass between the ruler and the central part of the mirror, you can easily measure the resulting recess. If it is not enough, continue grinding until you get the desired value (0.9mm in our case). If the grinding powder is of good quality, then rough grinding can be done in 1-2 hours.

Fine grinding.

In fine finishing, the surfaces of the mirror and grinder are rubbed against each other on a spherical surface with the highest precision. Grinding is done in several passes with increasingly fine abrasives. If during coarse grinding the center of pressure was located near the edges of the grinder, then with fine grinding it should be no more than 1/6 of the diameter of the workpiece from its center. At times it is necessary to make, as it were, erroneous movements of the mirror along the surface of the grinder, now to the left, then to the right. Start fine sanding only after a major cleaning. Large, hard particles of abrasive should not be allowed near the mirror. They have an unpleasant ability to "independently" seep into the grinding area and produce scratches. At first, use an abrasive with a particle size of 0.1-0.12 mm. The finer the abrasive, the smaller doses it should be added. Depending on the type of abrasive, it is necessary to experimentally select its concentration with water in suspension and the value of the portion. The time of its production (suspension), as well as the frequency of cleaning from sludge. It is impossible to allow the mirror to stick (get stuck) on the grinder. It is convenient to keep the abrasive suspension in bottles, in the corks of which plastic tubes with a diameter of 2-3 mm are inserted. This will facilitate its application to the work surface and protect it from clogging with large particles.

Check the progress of grinding by viewing the mirror in the light after rinsing with water. Large knockouts left after clumsy grinding should completely disappear, the haze should be completely uniform - only in this case, work with this abrasive can be considered finished. It is useful to work for an extra 15-20 minutes, in order to grind with a guarantee not only unnoticed punches, but also a layer of microcracks. After that, rinse the mirror, grinder, pallet, table, hands and proceed to grinding with one more, smallest abrasive. Add the abrasive suspension evenly, a few drops, after shaking the bottle. If too little abrasive suspension is added, or if there are huge deviations from the spherical surface, then the mirror can "grab". Therefore, you need to put the mirror on the grinder and make the first movements very carefully, without much pressure. Particularly ticklish is the "grabbing" of the mirror in the last stages of fine grinding. If such a threat has occurred, then in no case should you rush. Take the trouble evenly (for 20 minutes) to heat the mirror with a grinder under a stream of warm water to a temperature of 50-60 °, and then cool them. Then the mirror and the grinder will "disperse". You can tap with a piece of wood on the edge of the mirror in the direction of its radius, taking all precautions. Do not forget that glass is a very fragile and low heat-conducting material and at a very large temperature difference it cracks, as sometimes happens with a glass glass if boiling water is poured into it. Quality control at the final steps of fine grinding should be carried out using a powerful magnifying glass or microscope. In the final stages of fine grinding, the likelihood of scratches increases dramatically.

Therefore, we list the precautionary measures against their appearance:

perform painstaking cleaning and washing of the mirror, pallet, hands;

do wet cleaning in the work area after each approach;

try to remove the mirror from the grinder as little as possible. It is necessary to add abrasive by moving the mirror to the side by half the diameter, evenly distributing it according to the surface of the grinder;

putting the mirror on the grinder, press it, while large particles that accidentally fall on the grinder will be crushed and will not scratch the plane of the glass blank in any way.

Separate scratches or pits will not spoil the image quality in any way. However, if there are a lot of them, then they will lower the contrast. After fine grinding, the mirror becomes translucent and perfectly reflects the rays of light falling at an angle of 15-20 °. After making sure that this is the case, sand it still in the absence of any pressure, quickly turning it to equalize the temperature from the heat of the hands. If the mirror moves simply on a thin layer of the finest abrasive, with a slight whistle resembling a whistle through teeth, this means that its surface is very close to spherical and differs from it only by hundredths of a micron. Our task in the future during the polishing operation is not to spoil it in any way.

Mirror polishing

The difference between mirror polishing and fine polishing is that it is made on a soft material. High-precision optical surfaces are obtained by polishing on resin polishing pads. Moreover, the harder the resin and the smaller its layer on the surface of a hard grinder (it is used as the base of the polishing pad), the more accurate the surface of the sphere on the mirror is. To make a resin polishing pad, you first need to prepare a bitumen-rosin mixture in solvents. To do this, grind into small pieces 20 g of grade IV oil-bitumen and 30 g of rosin, mix them and pour into a bottle with a capacity of 100 cm3; then pour 30 ml of gasoline and 30 ml of acetone into it and close the cork. To speed up the dissolution of rosin and bitumen, periodically shake the mixture, and after a few hours the varnish will be ready. Apply a layer of varnish to the surface of the grinder and let it dry. The thickness of this layer after drying should be 0.2-0.3 mm. After that, pick up the varnish with a pipette and drip one drop onto the dried layer, preventing the drops from merging. What is very important is to evenly distribute the drops. After the varnish has dried, the polisher is ready for use.

Then prepare a polishing suspension - a mixture of polishing powder with water in a ratio of 1:3 or 1:4. It is also convenient to store it in a bottle with a stopper, equipped with a polyethylene tube. Now you have everything to polish the mirror. Moisten the surface of the mirror with water and put a few drops of polishing suspension on it. Then carefully place the mirror on the polishing pad and move it around. The movements for polishing are the same as for fine grinding. But you can press on the mirror only when it moves forward (shift from the polishing pad), it is necessary to return it to its original position without any pressure, holding its cylindrical part with your fingers. Polishing will go almost without noise. If the room is quiet, you can hear a noise that resembles breathing. Polish slowly, without pressing too hard on the mirror. It is important to set a mode in which the mirror under load (3-4 kg) goes forward rather tightly, and back easily. The polisher seems to "get used" to this mode. The number of strokes is 80-100 per minute. Make the wrong moves from time to time. Check the condition of the polisher. Its pattern should be uniform. If necessary, dry it and drip varnish in the right places, after thoroughly shaking the bottle with it. The polishing process should be monitored in the light, using a strong magnifying glass or a microscope with a magnification of 50-60 times.

The surface of the mirror should be polished evenly. It is very bad if the middle zone of the mirror or near the edges is polished faster. This can happen if the pad surface is not spherical. This defect must be immediately eliminated by adding bitumen-rosin varnish to the lowered places. After 3-4 hours, the work usually comes to an end. If you examine the edges of the mirror through a strong magnifying glass or microscope, then you will no longer see pits and small scratches. It is useful to work for another 20-30 minutes, reducing the pressure by two to three times and making stops for 2-3 minutes every 5 minutes of work. This ensures that the temperature equalizes from the heat of friction and hands and that the mirror acquires a more precise shape of a spherical surface. So, the mirror is ready. Now about the design features and details of the telescope. The views of the telescope are shown in the sketches. You will need few materials, and they are all available and relatively cheap. As a secondary mirror, you can use a total internal reflection prism from a large binocular, a lens or a light filter from a camera, on the flat surfaces of which a reflective coating is applied. As a telescope eyepiece, you can use an eyepiece from a microscope, a short-focus lens from a camera, or single plano-convex lenses with a focal length of 5 to 20 mm. It should be especially noted that the frames of the primary and secondary mirrors must be made very carefully.

The quality of the image depends on their correct adjustment. The mirror in the frame should be fixed with a small gap. The mirror must not be clamped in the radial or axial direction. In order for the telescope to provide a high quality image, it is necessary that its optical axis coincides with the direction to the object of observation. This adjustment is made by changing the position of the secondary auxiliary mirror, and then adjusting the nuts of the main mirror frame. When the telescope is assembled, it is necessary to make reflective coatings on the working surfaces of the mirrors and install them. The easiest way is to cover the mirror with silver. This coating reflects more than 90% of the light, but fades over time. If you master the method of chemical deposition of silver and take measures against tarnishing, then for most amateur astronomers this will be the best solution to the problem.

To magnify an observed astronomical object, you need to collect the light from this object and focus it (i.e. the image of the object) at some point.

This can be done either by a lens made of lenses or a special mirror.

Telescope types

*Refractors - light collects the lens objective. It also creates an image of an object at a point, which is then viewed through the eyepiece.

*Reflectors - light is collected by a concave mirror, then the light is reflected by a small flat mirror to the surface of the telescope tube, where the image can be observed.

*Mirror-lens (catadioptric) - both lenses and mirrors are used together.

Choosing a Telescope

Firstly, the magnification of the telescope is not its main characteristic! The main characteristic of all telescopes is the aperture= diameter of the lens (or mirror). A large aperture allows the telescope to collect more light, therefore, the observed luminary will be clearer, details will be better visible, higher magnifications can be applied.

Next, you need to find out which stores in your city sell telescopes. It is better to buy in stores that specialize in selling only telescopes and other optical instruments. Otherwise, carefully check the telescope: the lenses must be free of scratches, all eyepieces, assembly instructions, etc. are included. You can also order a telescope through an online store (for example, here). In this case, you will have more choice. Don't forget to find out how to ship the telescope and pay.

Pros and cons of the main types of telescopes:

Refractors: More durable and require less maintenance (because the lenses are in a closed tube). The image obtained through the refractor is more contrast and saturated. 100% transmits light (with an enlightened lens). Temperature changes have little effect on image quality.

-Refractors: more expensive than reflectors, the presence of chromatic aberration. (for apochromatic refractors it is less pronounced than for achromatic refractors) Small aperture.

Reflectors: Cheaper than refractors, no chromatic aberration, short tube length.